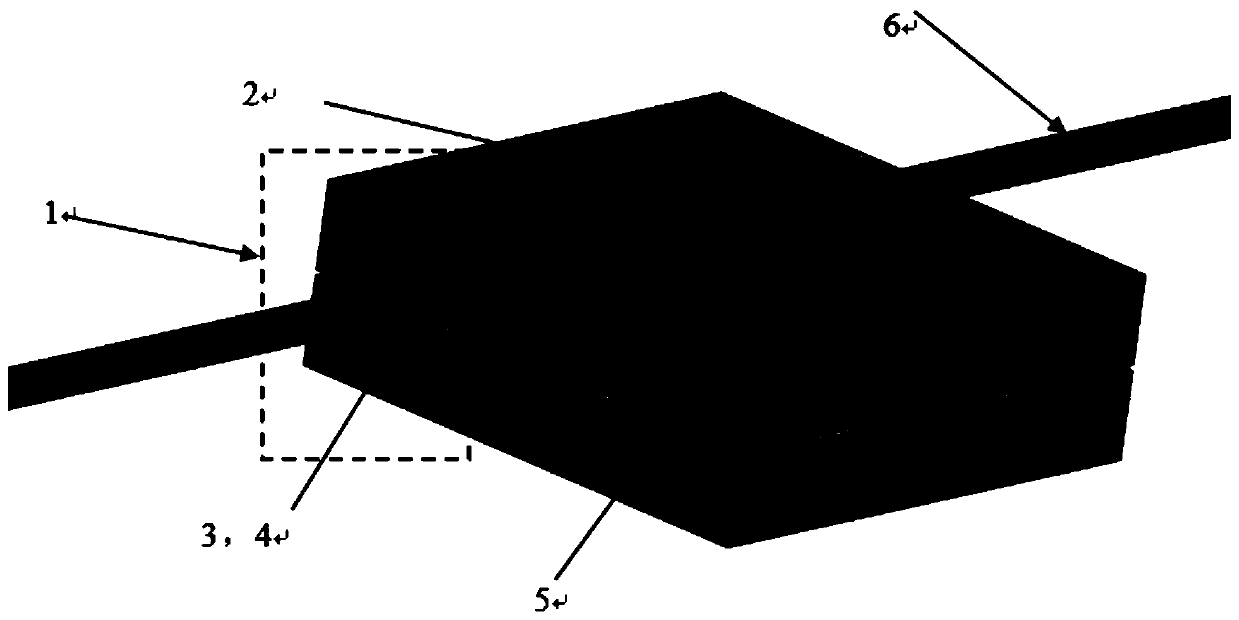

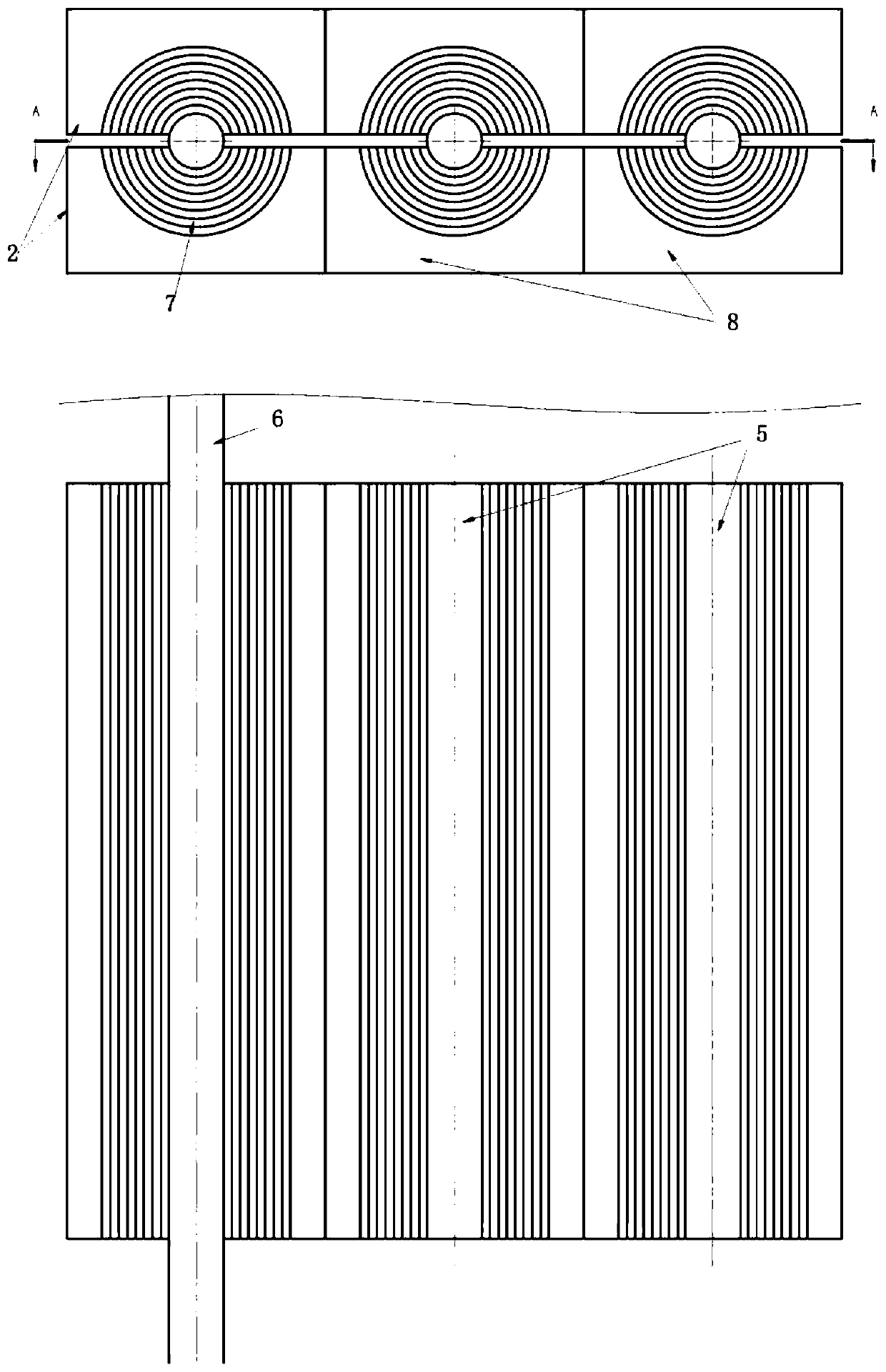

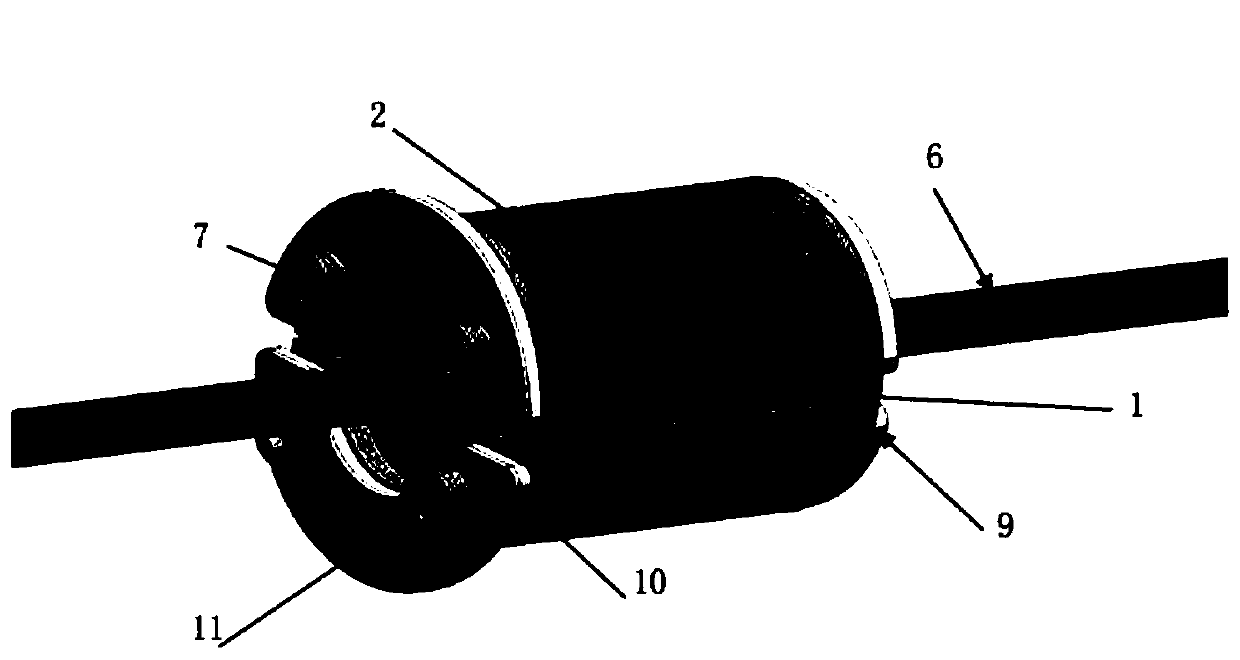

A cable duct sealing module

A cable duct and airtight technology, applied in the field of cable duct airtight modules, can solve the problems of cable damage, difficult cable construction, poor sealing effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The present invention also provides a preparation method of each component material, and the preparation method is a conventional technique in the field. Such as compounding and supplementary processing → raw rubber and compounding agent weighing → mixing → quality inspection.

[0082] The processing method of the base diaphragm is as follows:

[0083] Preparation process: heat refining (adding initiator and vulcanizing agent according to the corresponding proportion of the material) → blanking → vulcanization (vulcanization parameters of standard thickness: 180°C, 6min, pressure 20MPa, the actual vulcanization time of the matrix is calculated according to the equivalent vulcanization time, The pressure is calculated according to the area of the parting surface)→trimming→finished product.

[0084] The preparation methods not mentioned in the present invention are all conventional preparation methods in this field.

[0085] The materials used in the present inventi...

Embodiment 1

[0095] The first aspect of Embodiment 1 provides a cable duct sealing module, and each component material includes the following components by weight percentage.

[0096] 1) By weight percentage, the preparation material of the base comprises the following components:

[0097] 34% of silicon dioxide, 27% of rubber, 21% of aluminum hydroxide, 7.5% of alkane oil, 2.5% of kaolin, 0.3% of pigment, and 7.7% of other additives; said other additives include 4,4'-butylene bis( 6-tert-butyl-3-methylphenol) 0.3%, polyethylene glycol 0.8%, ethylene bisoleamide 0.6%, erucamide 0.2%, titanium dioxide 0.2%, di-tert-butyl peroxyisopropyl Benzene 0.7%, Stearamide 0.6%, Calcium Carbonate 4.3%. The pigment is carbon black.

[0098] 2) In terms of weight percentage, the preparation material of the rubber diaphragm 1 comprises the following components:

[0099] Aluminum hydroxide 29%, kaolin 27.5%, rubber 27%, calcium carbonate 4%, titanium dioxide 4.5%, alkane oil 2.5%, pigment 0.2%, other ad...

Embodiment 2

[0114] The first aspect of Embodiment 2 provides a cable duct sealing module, and each component material includes the following components by weight percentage.

[0115] 1) By weight percentage, the preparation material of the base comprises the following components:

[0116] 33% of silicon dioxide, 25% of rubber, 20% of aluminum hydroxide, 7% of alkane oil, 2% of kaolin, 0.1% of pigment, and 2.5% of other additives; said other additives include 4,4'-butylene bis( 6-tert-butyl-3-methylphenol) 0.2%, polyethylene glycol 0.6%, ethylene bisoleamide 0.5%, erucamide 0.1%, titanium dioxide 0.1%, di-tert-butyl peroxyisopropyl Benzene 0.6%, stearamide 0.4%. The pigment is carbon black.

[0117] 2) In terms of weight percentage, the preparation material of the rubber diaphragm 1 comprises the following components:

[0118] Aluminum hydroxide 29%, kaolin 27%, rubber 26%, calcium carbonate 4%, titanium dioxide 4%, alkane oil 2%, other additives 1%; said other additives are polyisobuty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com