Wood processing machine tool capable of automatically pushing wood

A technology for processing machine tools and pushing mechanisms, which is applied to wood processing appliances, processing machines for manufacturing flat surfaces, and special forming/shaping machines. Achieve the effect of ingenious structure, reduced labor intensity and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

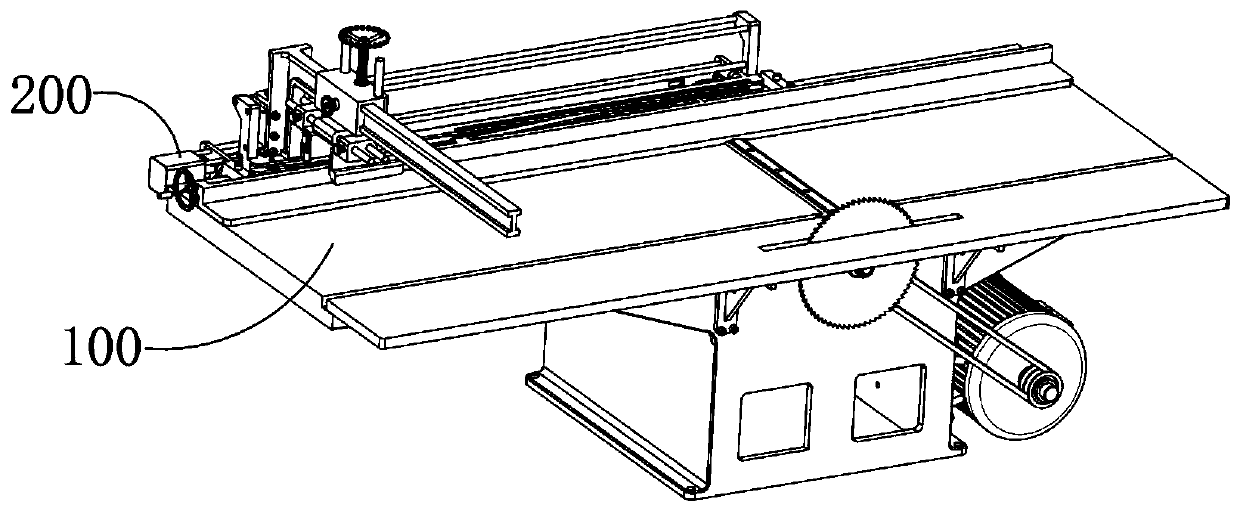

[0060] A wood processing machine tool that automatically pushes wood, which includes a planer body 100, a traveling drive device 200, and a retraction reset device 300. The planer body 100 includes a rectangular front panel 102 and a rear panel 103 arranged horizontally, and a bed arranged below the two The body 101 supports it, and a planing mechanism 110 is arranged between the front board 102 and the back board 103. An automatic pushing mechanism 130 is also movable, and the automatic pushing mechanism 130 is used to push the wood workpiece close to the front panel 102 and move to the back panel 103 after being planed by the planing mechanism 110. The driving device 200 is connected with the automatic pushing mechanism 130 and used In order to provide pushing power to the automatic pushing mechanism 130 , the retraction reset device 300 is used to cut off the power output of the traveling driving device 200 and control the traveling driving device 200 and the automatic pushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com