Machining device for automobile parts

A technology of auto parts and processing devices, which is applied in the field of parts processing, and can solve the problems of occupying production workshop space, requiring more equipment, and a large number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

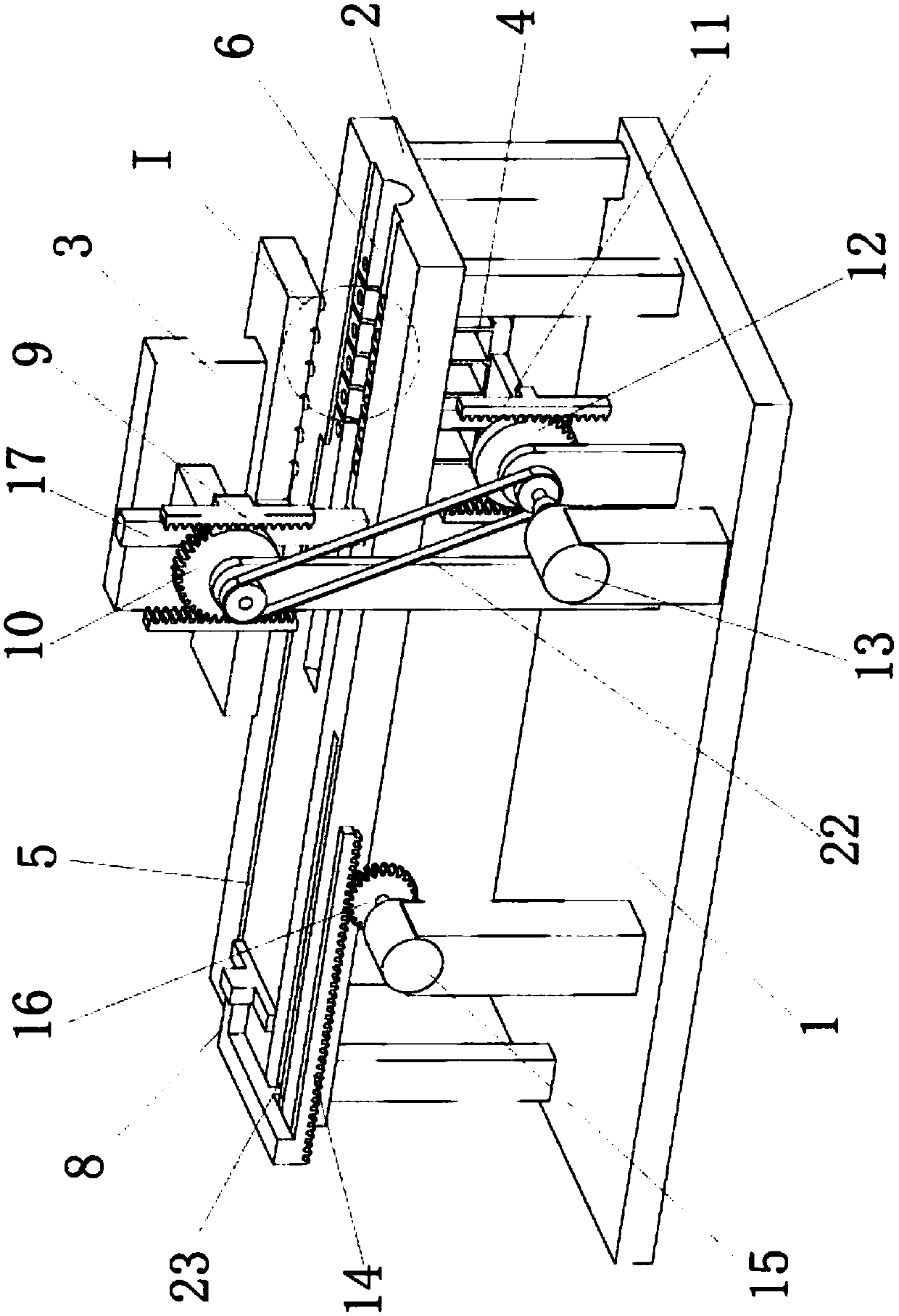

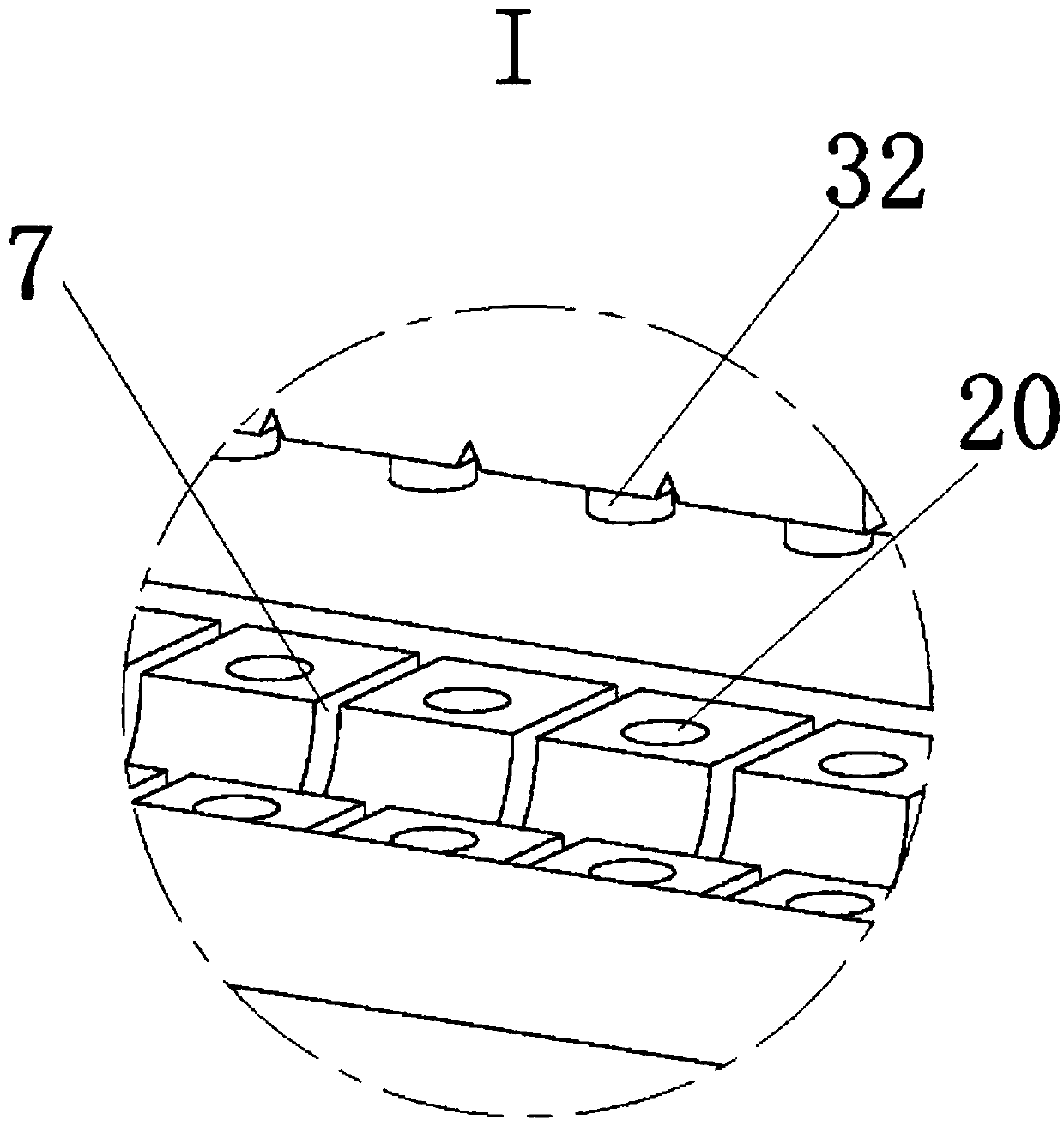

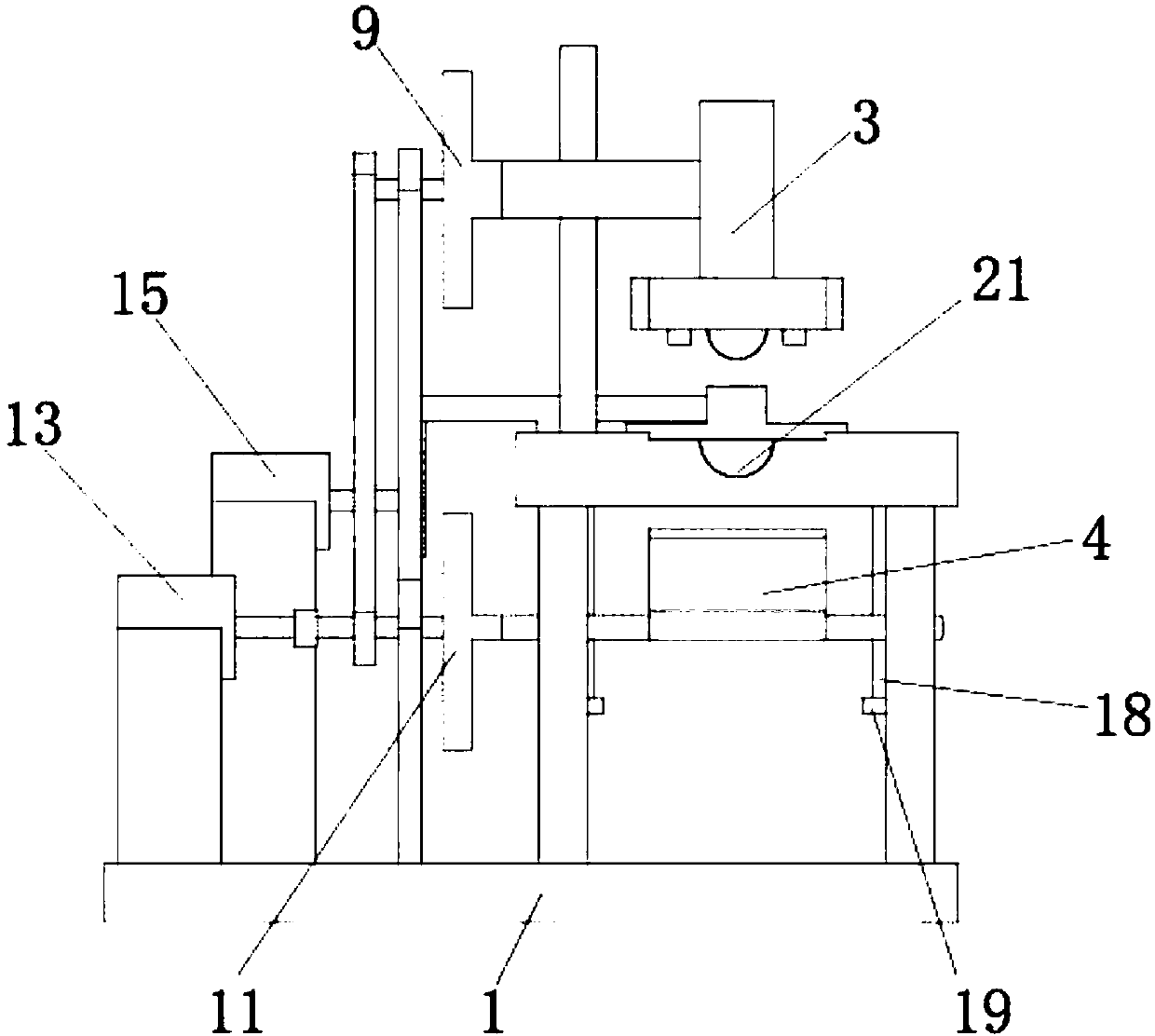

[0025] Such as Figure 1 to Figure 6 As shown, an auto parts processing device includes a base plate 1, a platform 2 fixed on the base plate 1, a vertically reciprocating sliding punch 3 is installed above the platform 2, and a vertical reciprocating mold is installed below the platform 2. Sliding cutter 4, the punch 3 and the cutter 4 are jointly connected with a power unit, the platform 2 is provided with a feed passage 5, and the feed passage 5 is provided with a die 6 that cooperates with the punch 3, The die 6 is provided with a knife edge 7 matching with the cutter 4, and the left end of the platform 2 is provided with a pushing block 8 matching with the feeding channel 5, and the pushing block 8 is connected with a pushing device.

[0026] In this way, under the push of the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com