A method of assembling an engine

An assembly method and engine technology, which is applied in the direction of machines/engines, assembly machines, mechanical equipment, etc., can solve the problems of uneven volume of combustion chambers and the impact of cylinder gasket sealing on the volume of combustion chambers, so as to achieve consistent volumes and avoid combustion chamber volumes Variation, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the reference numerals refer to components and techniques in the present invention, so that the advantages and features of the present invention can be more easily understood in a suitable environment. The following description is the embodiment of the claims of the present invention, and other specific implementations related to the claims that are not explicitly described also belong to the scope of the claims.

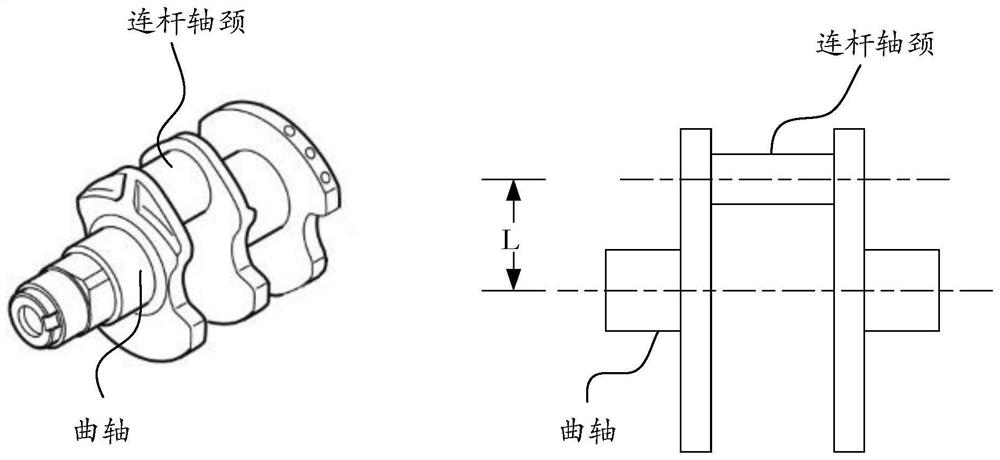

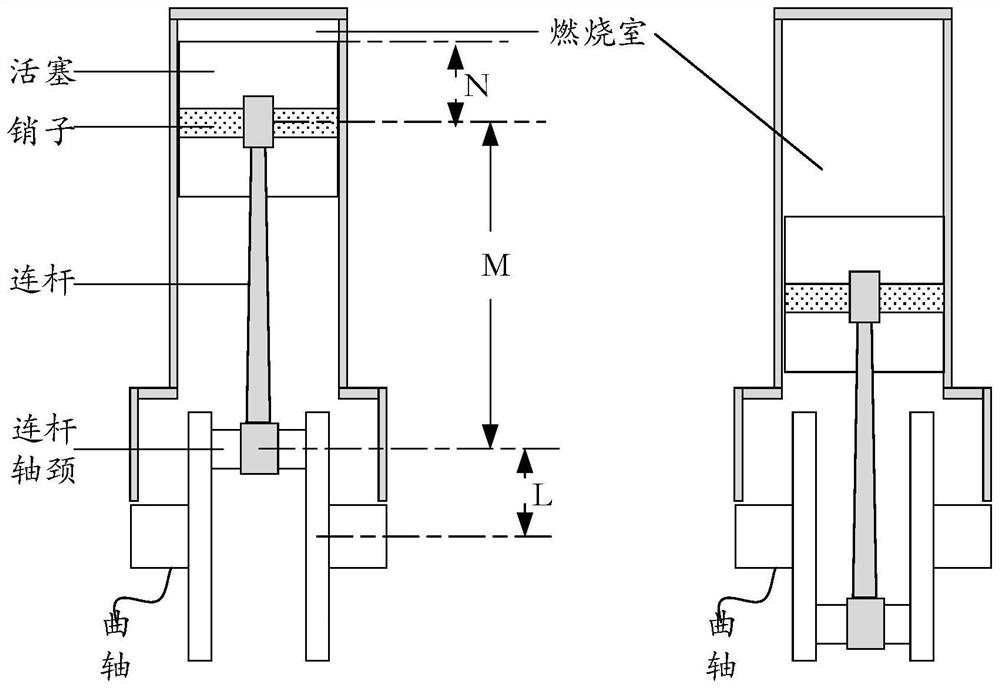

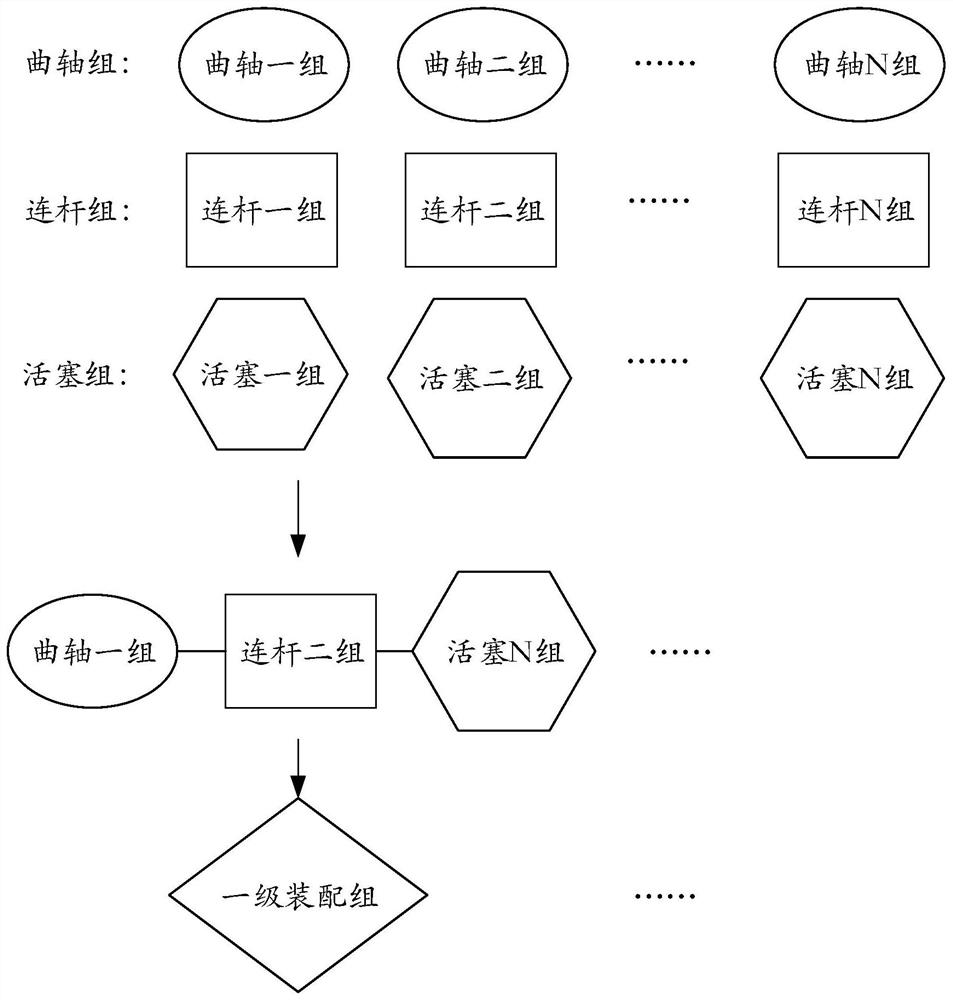

[0024] The invention provides an assembly method of an engine, which includes obtaining the rotation diameter tolerance of the connecting rod journal of the crankshaft as the crankshaft tolerance; obtaining the length tolerance of the connecting rod as the connecting rod tolerance; obtaining the tolerance of the distance from the pin hole to the top of the piston as the piston tolerance ; Select the crankshaft, connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com