A positioning device and method for cleaning billet corners

A positioning device and casting billet technology, applied in the field of casting billet corner cleaning, can solve the problems of loss of heat energy, increase carbon emissions, products that cannot meet the requirements of heat transfer, etc., and achieve the effect of filling technical gaps and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

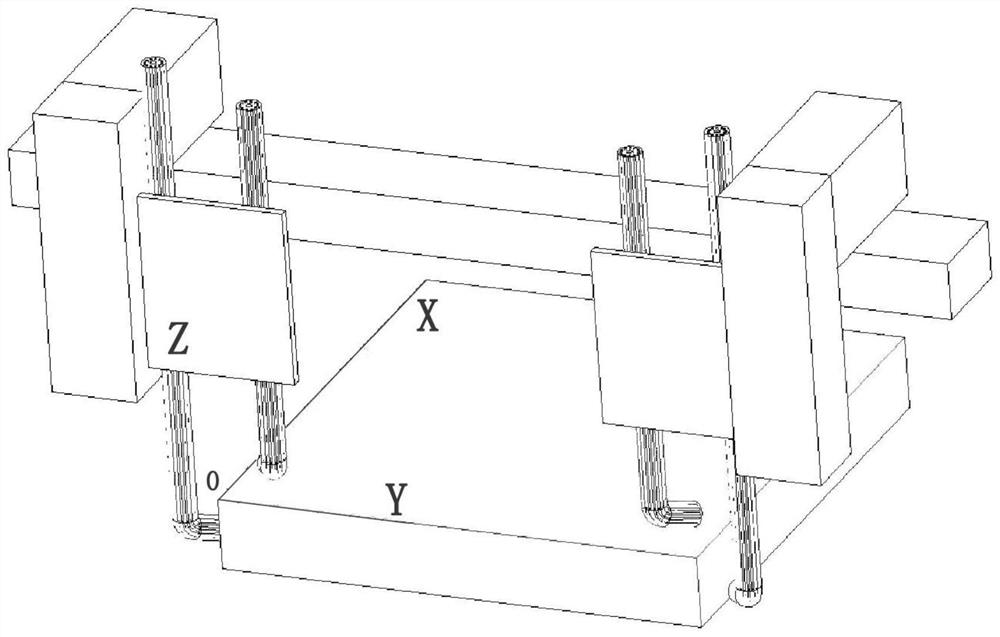

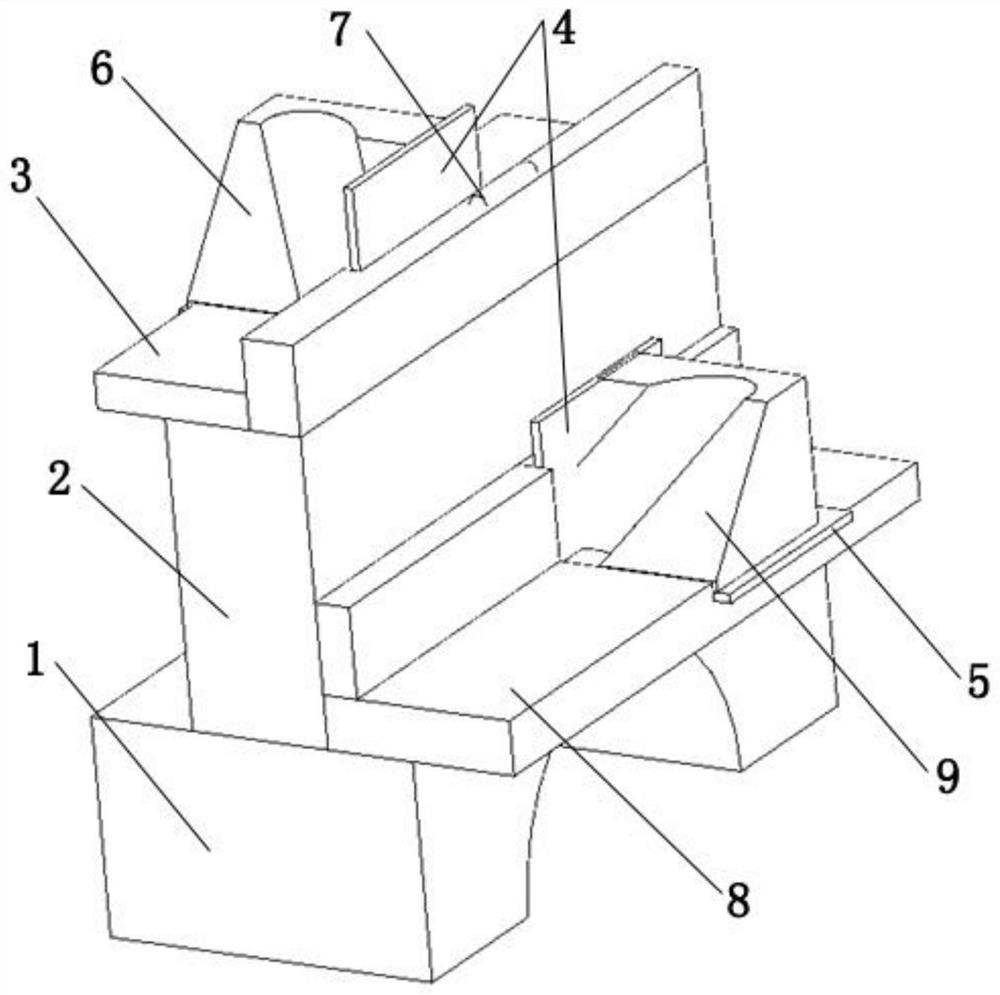

[0051] See Figure 1-Figure 4 , a positioning method for billet corner cleaning, taking a 115° cleaning gun as an example, includes the following steps:

[0052] 1) Device positioning: fix the positioning device horizontally on the roller table 10 below the corner cleaning machine through the magnetic base 1, the arc-shaped semi-cylindrical surface at the bottom of the magnetic base 1 contacts the upper surface of the roller table 10, adjust the angle of the magnetic base 1, and observe the level 7. Make sure that the hot billet imitation block 2 is in a horizontal position, fix the positioning device on the roller table 10 through the magnetic base 1, place the inner arc gun angle adjustment block 6 on the inner arc gun positioning seat 3, and select a 25° inner arc The gun angle adjustment block 6 is placed on the inner arc positioning seat;

[0053] 2) Positioning of the corner cleaning machine: move the corner cleaning machine cart along the X-axis direction, move the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com