Semiautomatic feeding device

A feeding device, semi-automatic technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as dust spillage and easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

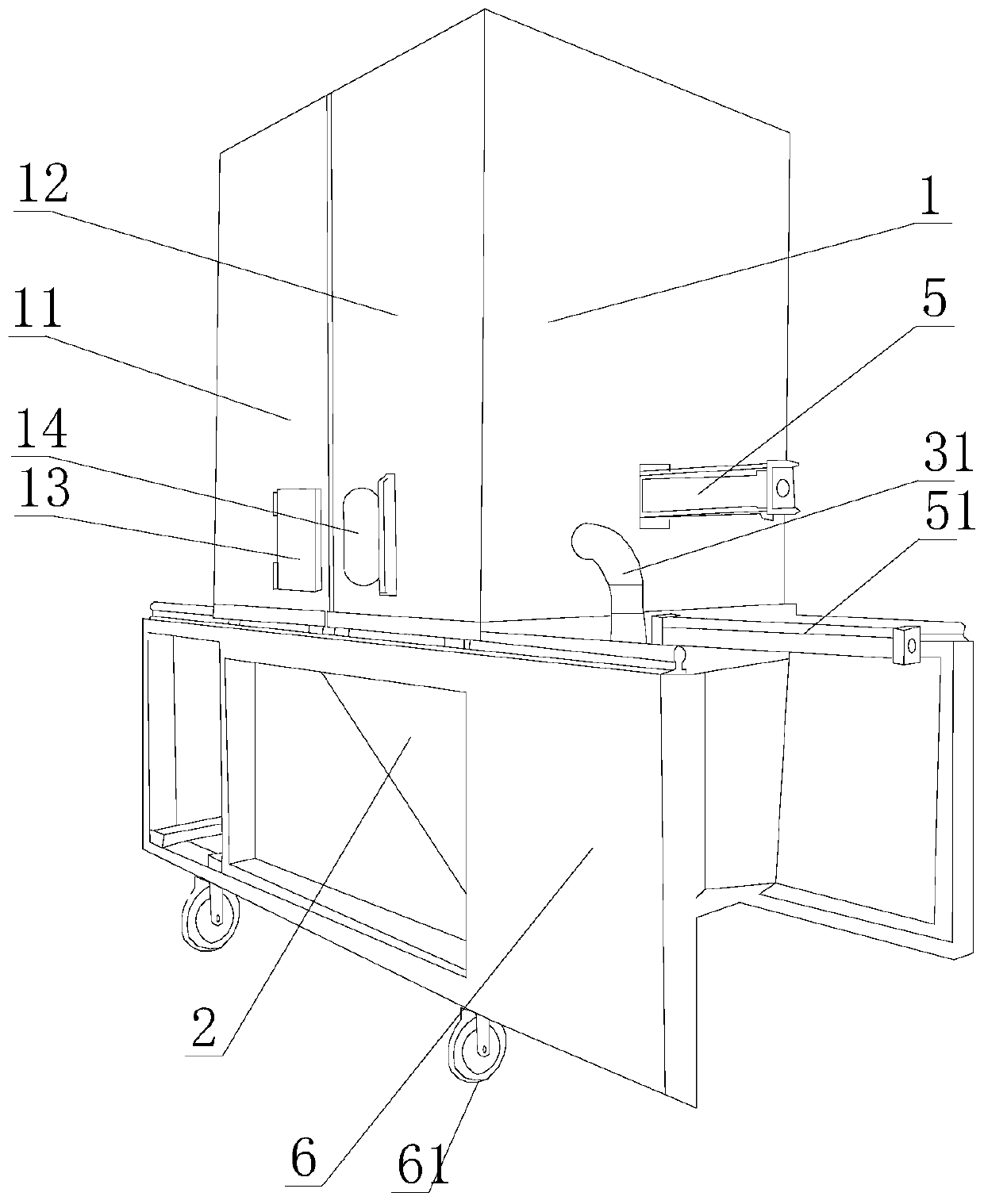

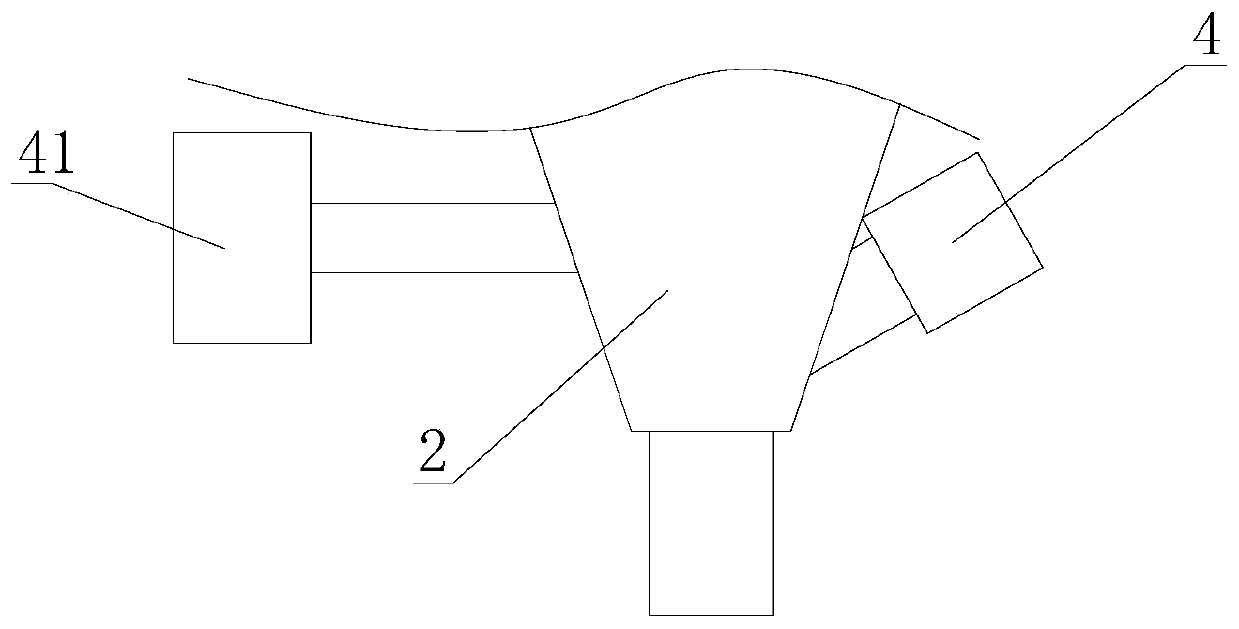

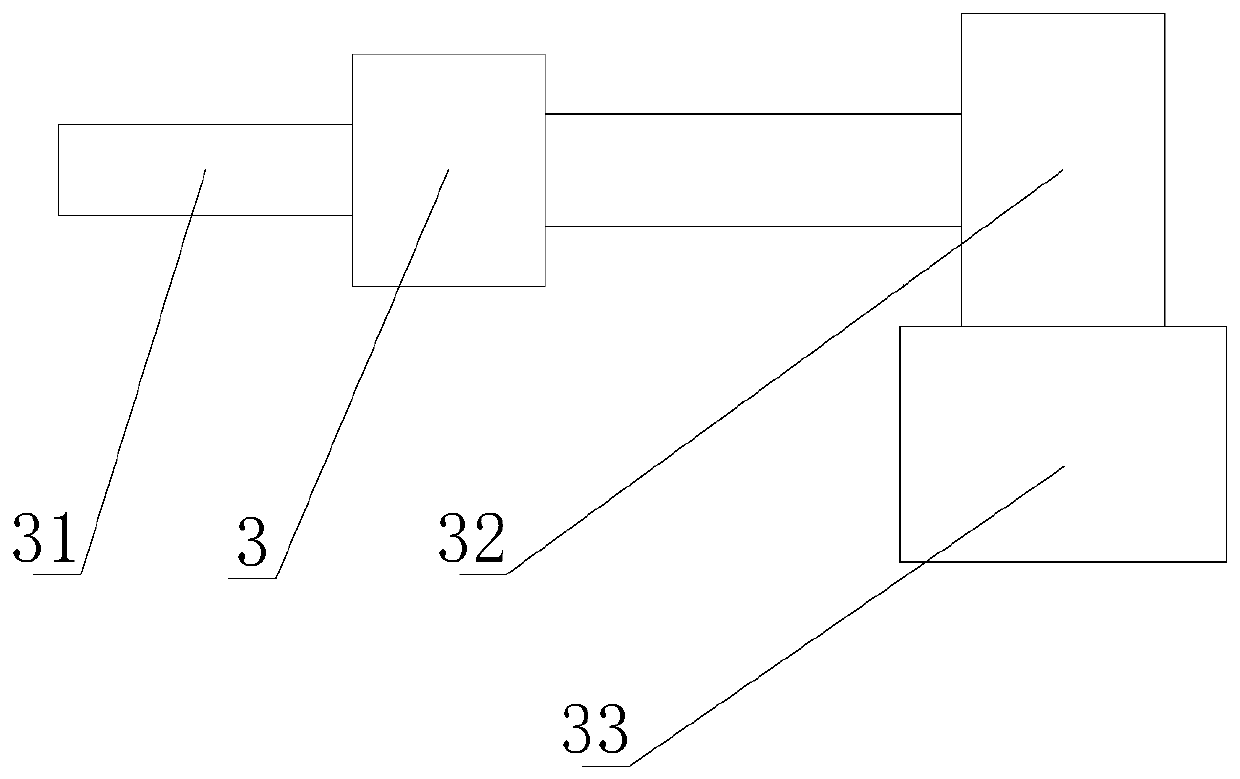

[0029] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides a semi-automatic feeding device, including: an open-close type airtight cabin 1; a lower hopper 2 arranged under the open-close type airtight cabin 1; The electric dust collector 3 for dust removal in the sealed cabin 1, the electric dust collector 3 communicates with the open-close sealed cabin 1 through the first dust removal pipe 31; the electric dredging screw group arranged in the lower hopper 2.

[0030] Through the open and close sealed cabin, it is convenient to put the material into it, and the bag is opened and unloaded in the opened and closed sealed cabin. In order to prevent dust from overflowing, the open and closed sealed cabin is sealed during the bag opening process, and the electric dust removal device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com