Brown coconut juice beverage and preparation method thereof

A coconut juice and beverage technology, applied in the field of brown coconut juice beverage and its preparation, can solve the problems of single type and taste, and achieve the effects of energy saving, full taste and pure taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] A kind of preparation method of above-mentioned brown coconut juice drink, comprises the following steps:

[0056] Coconut milk preparation: Weigh the ultra-high temperature sterilized coconut milk or pasteurized coconut milk according to the formula, and set aside. used in it

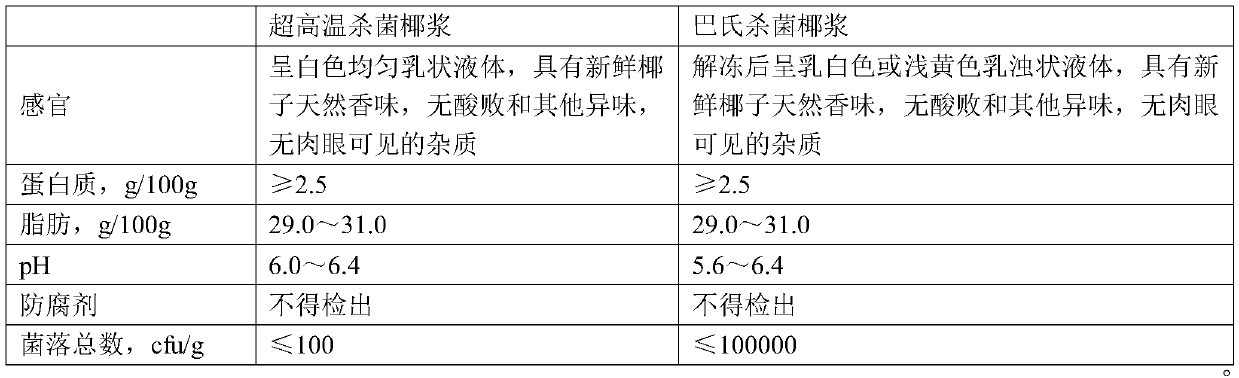

[0057] Coconut milk raw materials meet the following standards:

[0058]

[0059]

[0060] Wherein, the preparation method of the ultra-high temperature sterilized coconut milk is as follows: select raw coconut trichomes, and then sequentially perform shell breaking, peeling, cleaning, pressing, vibration screening, pasteurization and standardization, and sterilization at 140-148°C. The preparation method of the pasteurized coconut milk is as follows: raw coconut trichomes are selected, followed by shell breaking, peeling, cleaning, pressing, vibration screening, pasteurization and standardization, filling, and quick freezing below -30°C.

[0061] 2) Dissolving and emulsifying agent:

...

Embodiment 1

[0075] The weight of each component of this embodiment is calculated based on the total amount of 1000mL: 54 grams of white granulated sugar, 12 grams of fructose syrup, 70 grams of ultra-high temperature sterilized coconut milk, 6 grams of sodium caseinate, 3.2 grams of glyceryl monostearate, sucrose 0.8 grams of fatty acid esters, 0.7 grams of xanthan gum, 0.8 grams of potassium citrate, 0.2 grams of sodium tripolyphosphate, 1.0 grams of potassium chloride, 0.3 grams of baking soda, and the rest is water.

[0076] The manufacturing steps of this embodiment are as follows:

[0077] 1) Coconut milk preparation: Weigh the ultra-high temperature sterilized coconut milk required by the formula and set it aside. Wherein, the preparation method of the ultra-high temperature sterilized coconut milk is as follows: select the raw coconut trichomes, and then sequentially perform shell breaking, peeling, cleaning, pressing, vibration screening, pasteurization and standardization, and st...

Embodiment 2

[0090] The weight of each component of this embodiment is calculated based on the total amount of 1000mL: 48 grams of white granulated sugar, 20 grams of glucose, 68 grams of ultra-high temperature sterilized coconut milk, 5.4 grams of sodium caseinate, 3.2 grams of glyceryl monostearate, sucrose fatty acid 0.5 grams of esters, 0.7 grams of xanthan gum, 1.0 grams of potassium citrate, 0.8 grams of potassium chloride, 0.3 grams of baking soda, and the rest is water.

[0091] The manufacturing steps of this embodiment are as follows:

[0092] 1) Coconut milk preparation: Weigh the ultra-high temperature sterilized coconut milk required by the formula and set it aside. Wherein, the preparation method of the ultra-high temperature sterilized coconut milk is as follows: select the raw coconut trichomes, and then sequentially perform shell breaking, peeling, cleaning, pressing, vibration screening, pasteurization and standardization, and sterilization at 148°C.

[0093] 2) Dissolvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com