Precise control device and method for grain unloading of harvester at edge of field

A technology for precise control and harvesting machines, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as energy waste, affecting operation efficiency, and reducing harvesting operation efficiency, so as to reduce labor intensity, avoid turning back, and improve Effect of Harvesting Operation Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

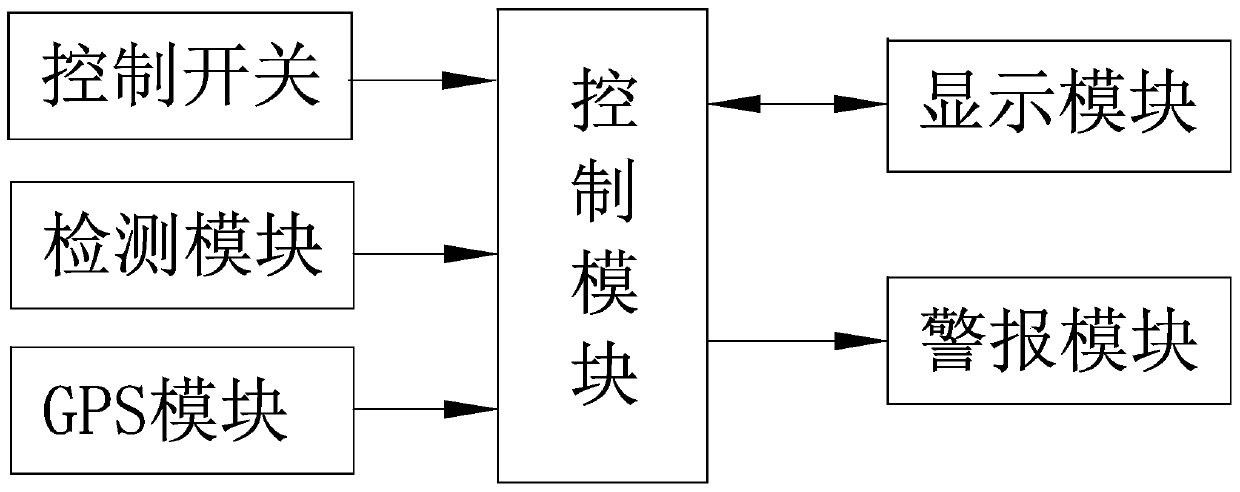

[0055] Such as image 3 and Figure 4 As shown together, a precise control device for grain unloading on the ground of a harvester, wherein the harvester has its own granary; the precise control device for grain unloading on the ground in this embodiment includes: a control module, a control switch, a detection module, a GPS module, a display module and an alarm module.

[0056] Wherein, the control switch is electrically connected with the control module, and is used for activating the control module to make it work. The detection module is installed at the full position of the granary and is electrically connected to the control module. The detection sensing surface of the detection module faces the bottom of the granary. The detection module is used to detect the height H from the upper surface of the grain in the granary to the full position m ; The detection module includes a photoelectric sensor or an infrared sensor, or even an ultrasonic sensor. The GPS module is in...

Embodiment 2

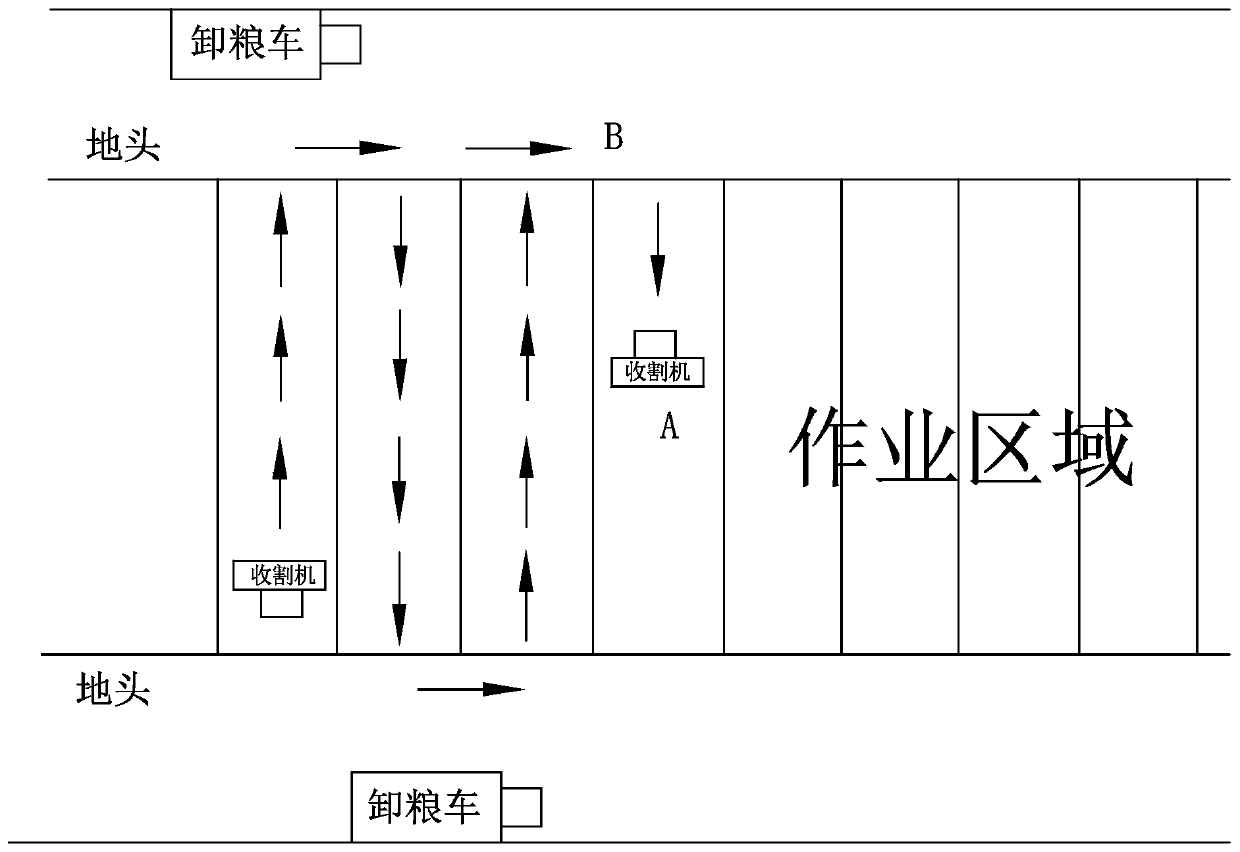

[0062] The present invention takes the situation that grain can be unloaded on both sides of the work area (the fields on both sides are accompanied by grain unloading trucks) as the second embodiment; this embodiment is explained with regular plots, but irregular plots can be infinitely close to regular plots The integration of blocks is also applicable to the present invention.

[0063] Such as Figure 5 to Figure 7 Commonly shown, this embodiment provides a precise control method for grain unloading on the ground using the above-mentioned precise control device for grain unloading on the ground of the harvester. The precise control method for grain unloading on the ground includes control steps for grain unloading on both sides:

[0064] S0. Use the above buttons or touch buttons to select the grain unloading mode as the grain unloading mode on both sides.

[0065] S1. Initialize the internal parameters of the control module.

[0066] S2. Determine whether the control swi...

Embodiment 3

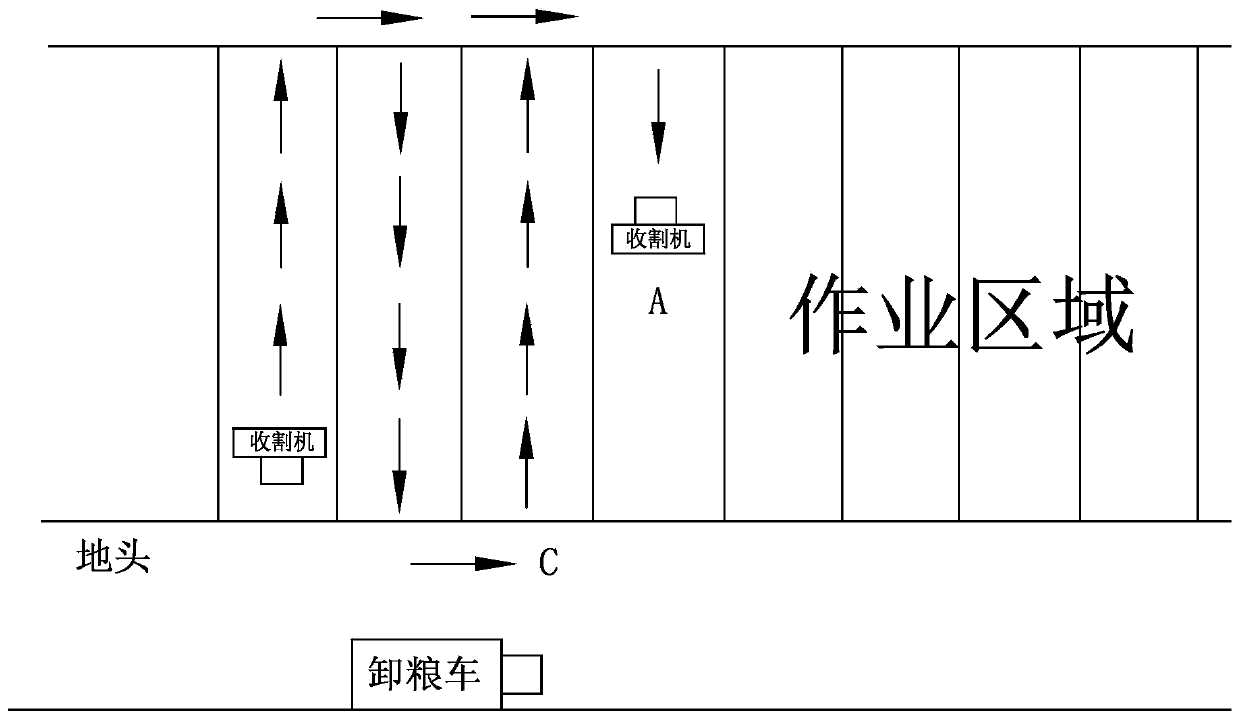

[0079] The present invention takes the situation that grain can be unloaded on one side of the field in the work area (the work area has a head on one side, and there is a grain unloading vehicle on the head) as the third embodiment; this embodiment is also described with regular land, but not The integration of regular plots that can be infinitely close to regular plots is also applicable to the present invention.

[0080] Such as Figure 7 to Figure 9 Commonly shown, the present embodiment provides a method for precise control of grain unloading on the ground using the above-mentioned precise control device for grain unloading on the ground of the harvester. The steps different from those in Example 2 are described in detail):

[0081] Execute the above step S1 to the above step S5, and then execute step S60.

[0082] S60, the control module judges whether n is greater than or equal to 4, if yes, execute step S70; if not, execute step S5.

[0083] S70, the control module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com