Light splitter

A technology of optical splitter and optical splitter, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of troublesome maintenance of optical splitter, easy failure, uneven light distribution, etc., so as to reduce the frequency of replacement and use cost, and prolong the use Lifespan, uniform light distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

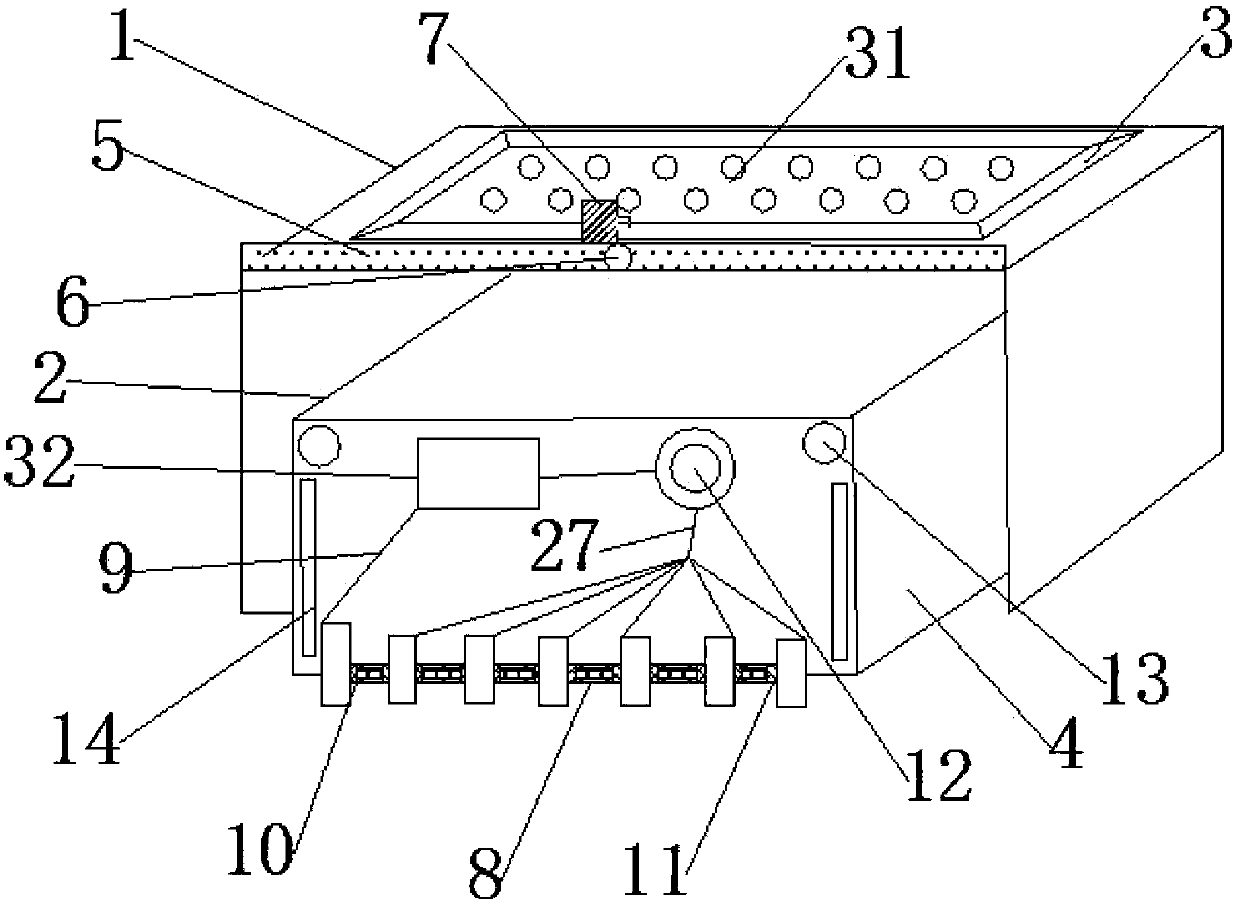

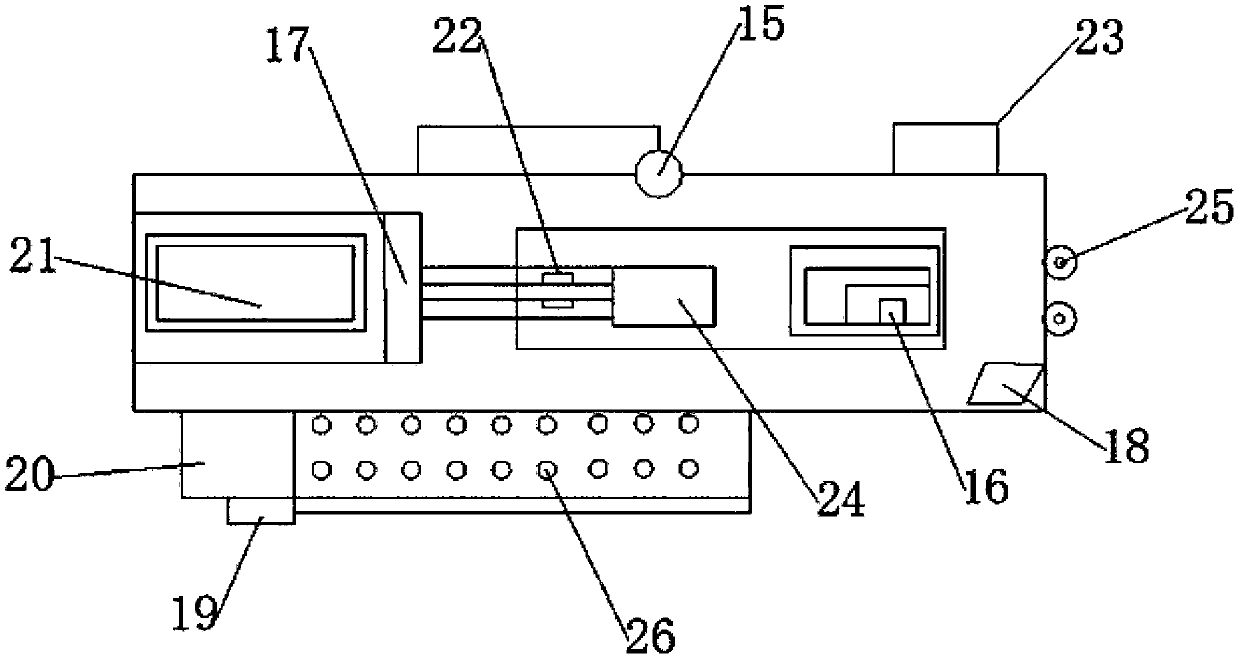

[0029] An optical splitter, comprising an optical splitter body, the optical splitter body includes a casing 1 and a box body 2, the casing 1 is slidably connected to the box body 2, the upper end of the box body 2 is provided with a panel 3, the box body A partition 4 is provided inside the body 2, and a hole 31 is provided on the panel 3; a shunt element 32 is provided inside the box body 2;

[0030] Further, the upper end of the housing 1 is provided with a chute 5, and the upper end of the chute 5 is provided with a scraper 7; the chute 5 is provided with a slide bar 6, and the slide bar 6 is located at the front and rear ends of the scraper 7 , the bottom end of the scraper 7 is attached to the shell 1; when the upper end of the shell 1 is contaminated with dirt, you only need to hold the slide bar 6 to move left and right, and the slide bar 6 will drive the scraper 7 along the slide The groove 5 moves left and right, and since the bottom end of the scraper 7 is attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com