Semi-grouting sleeve fullness inspection device and using method

A technology of semi-grouting sleeve and inspection device, applied in the direction of measuring device, structural elements, building components, etc., can solve the problems of difficult inspection of grouting fullness, economic loss, and difficulty in filling grouting, and achieve the effect of intuitive and reliable monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

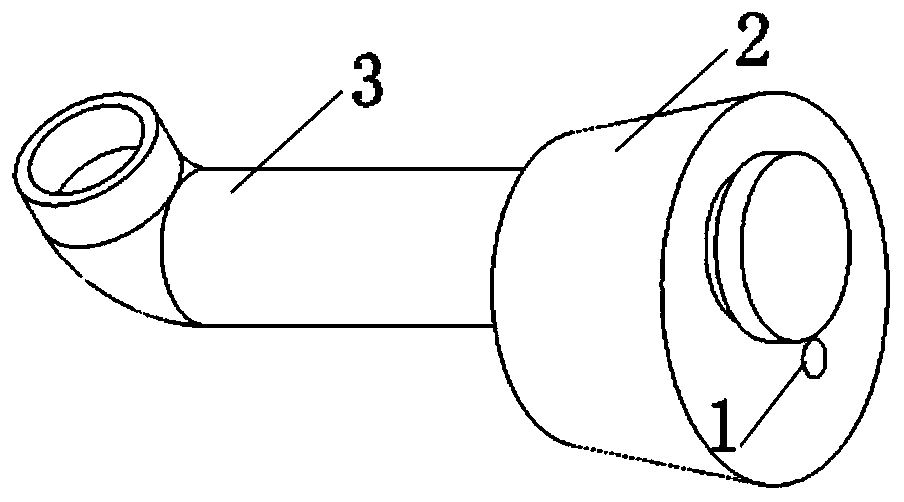

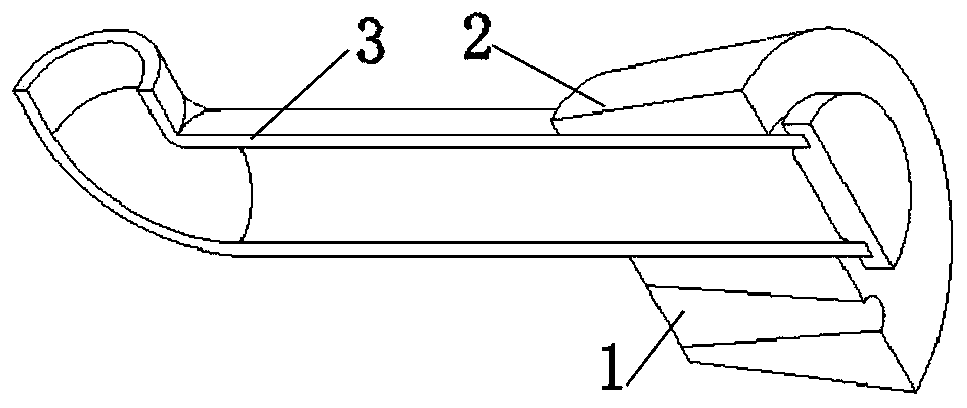

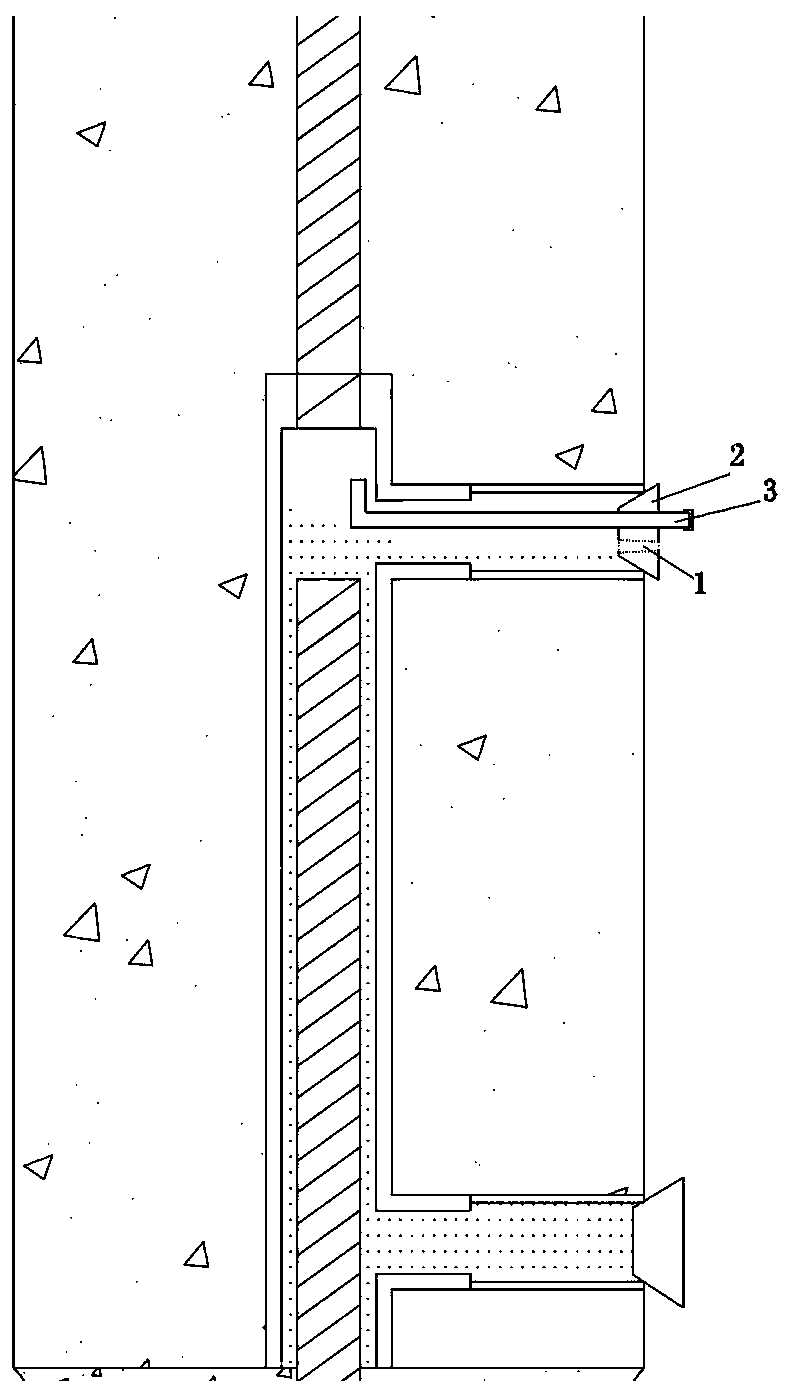

[0028] like Figure 1-3 As shown, the present invention provides a device for inspecting the fullness of a semi-grouting sleeve, which includes a vent plug 1, a detection tube 2, a slurry outlet plug 3 and an industrial endoscope, and the slurry outlet plug 3 It is in the shape of a truncated cone and has a horizontal through hole on the upper side, and a truncated circular through hole on the lower side. The smaller end of the truncated circular through hole is set on the side with a larger diameter of the plug of the pulp outlet; The air vent plug 1 is arranged in the frustum-shaped through hole of the pulp outlet plug 3; the detection tube 2 is arranged in the horizontal through hole of the pulp outlet plug 3, and The end at the corner is set horizontally upwards, and the detection tube 2 has a detachable airtight seal at the end outside the grout outlet plug, which can effectively prevent the grout from entering the detection tube 2 during grouting, resulting in failure of...

Embodiment 2

[0037] like Figure 4 and Figure 5 As shown, the difference between this embodiment and Embodiment 1 lies in the detection tube 2, and the other end of the detection tube 2 in this embodiment is flush with the inner side of the pulp outlet plug.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com