Continuous separating and drying system for wet-process production of insoluble sulfur

A soluble and wet technology, which is applied in the field of continuous separation and drying systems, can solve the problems that the working efficiency of the vacuum filter cannot be matched, the production efficiency of insoluble sulfur cannot be improved, and the vacuum filter is intermittent, so as to ensure normal transportation and avoid The effect of material blocking and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

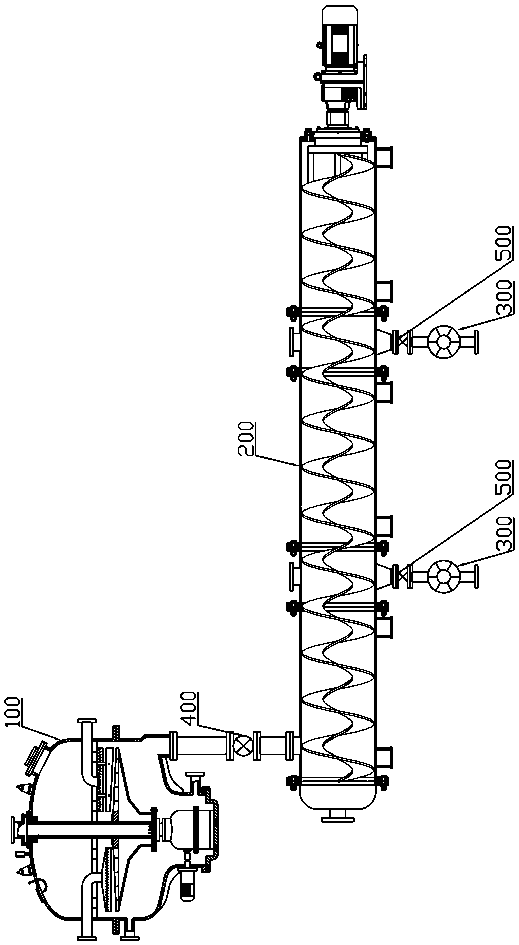

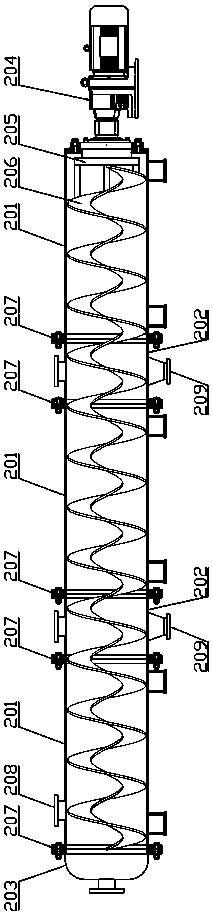

[0022] Such as Figure 1~Figure 5 As shown, the continuous separation and drying system for wet production of insoluble sulfur includes vacuum filtration device, conveying device and vacuum drying device:

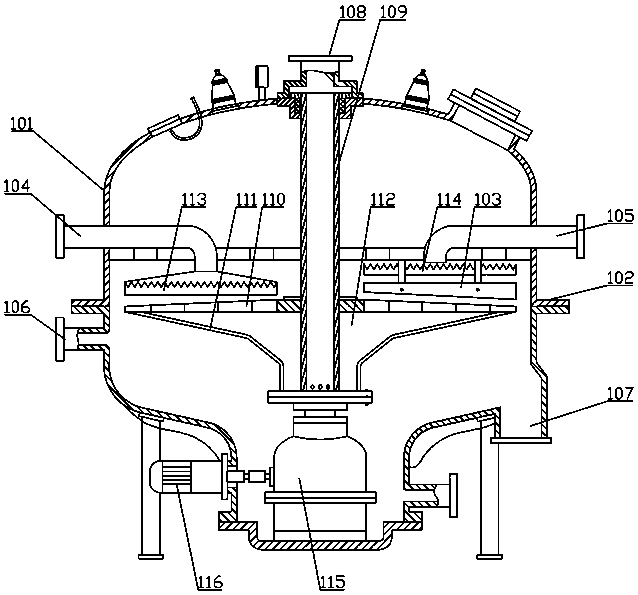

[0023] The vacuum filtration device includes a deoiling shell 101, a blanking scraper, a turntable drive mechanism and a suction filter mechanism. The deoiling shell 101 is formed by joining the upper and lower shells through the flange structure 102. The deoiling shell 101 is equipped with a slurry feeding inlet, lotion inlet, balance gas inlet, solid outlet and mother liquor suction filter port, the slurry inlet is equipped with a slurry feed pipe 104, the lotion inlet is equipped with a lotion feed pipe 105, and the balance gas inlet is equipped with a gas inlet The material pipe 106, the solid outlet is equipped with a solid discharge joint 107, the mother liquor suction filter port is equipped with a suction filter joint 108, the suction filter mechanism includes a suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com