A statistical method for the electronic manufacturing industry

A statistical method and manufacturing technology, applied in the field of statistics, can solve problems such as low reliability, undetectable SPC, outliers, etc., and achieve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

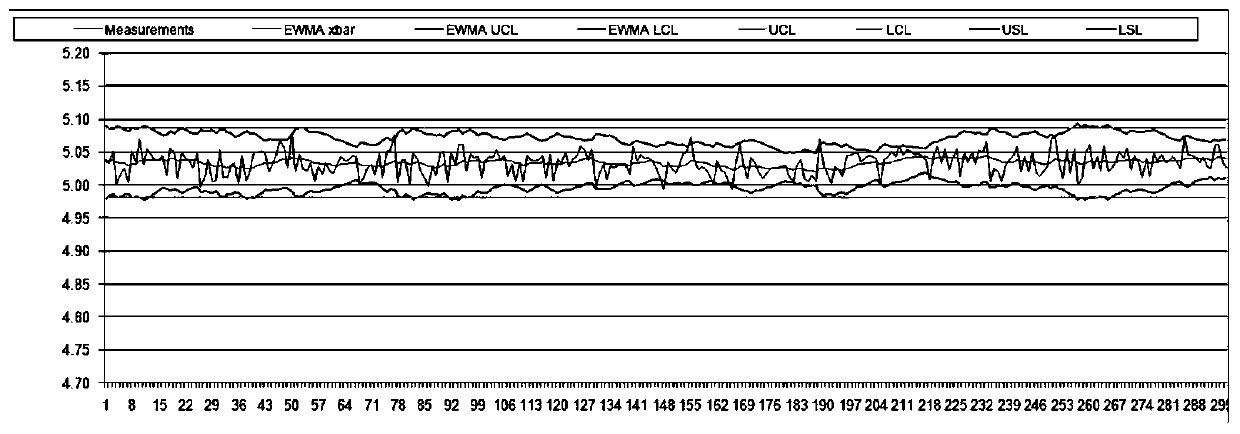

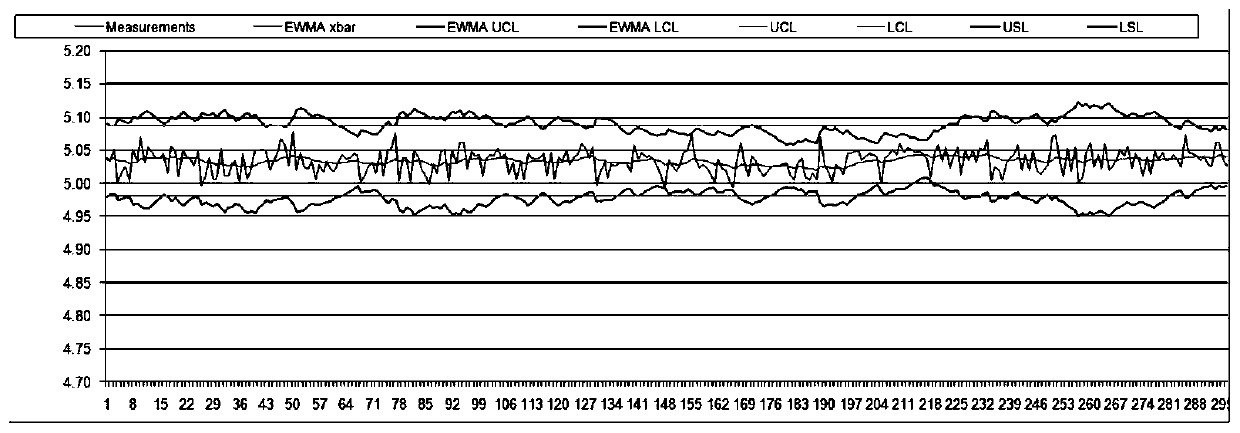

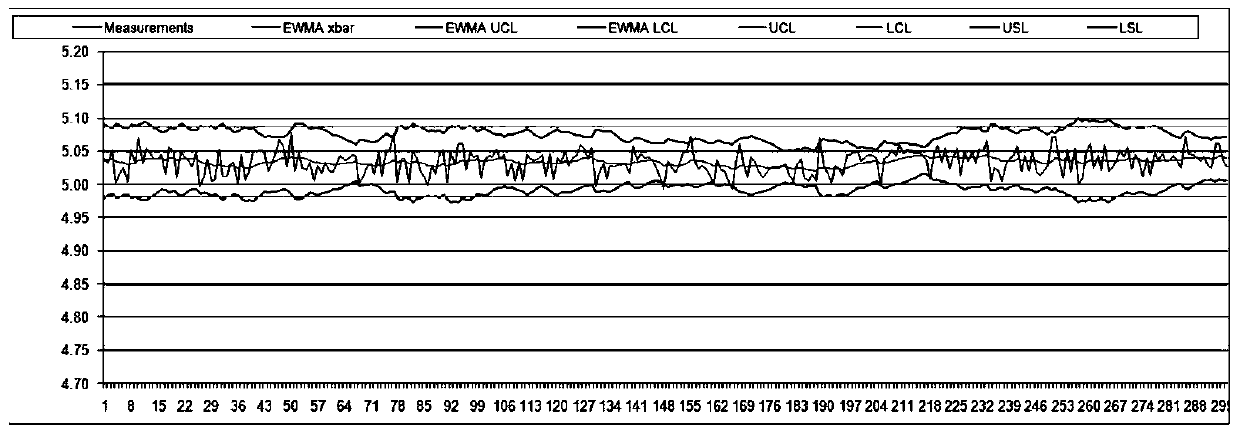

[0031] Embodiment 1: as Figure 1 to Figure 5 One statistical method shown for electronics manufacturing, including SPA (Statistical Dynamic Adjustment) with control limits determined by the following formula:

[0032] (Formula 1) UCL i=[Xbar i+αABS(Xi-Xi-1)]*β+(1-β)UCLi-1;

[0033] (Formula 2) LCL i=[Xbar i-αABS(Xi-Xi-1)]*β+(1-β)LCLi-1;

[0034](Formula 3) Xbar i=Xi*β+Xbar i-1(1-β);

[0035] The "α" in the formulas 1 and 2 refers to the α risk, which means that the product should be rejected according to the customer's specification boundary, and the "β" is β risk. Products judged to be defective are accepted. The larger the α, the longer the distance between the upper and lower control boundaries of the SPA, and the fewer "outliers" are screened out. The smaller the α, the greater the distance between the upper and lower control boundaries of the SPA. The narrower the distance between , the more "outliers" are screened out, the larger the β, the faster the change frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com