Device suitable for acoustic triaxial test, and implementation method thereof

A technology of triaxial test and implementation method, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problems of inability to complete the test, different microstructures, constant contact force, etc., to achieve calculation The results are accurate and reliable, the calculation method is simple, and the confining pressure and flow rate are stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A device suitable for acoustic triaxial test and its implementation method of the present invention will be described with reference to the accompanying drawings.

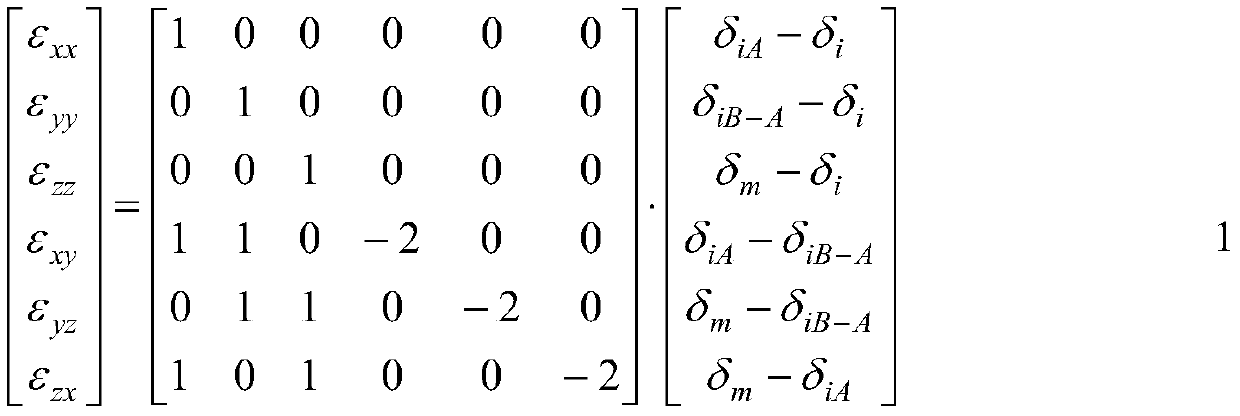

[0027] The device of the present invention suitable for acoustic triaxial test and its implementation method are based on the fact that the rigid shell ensures the zero deformation of the acoustic coupling material, and the stability of the confining pressure is achieved through the progressive compression of the multi-stage chamber body , Calculate the stress state of one point through 6 independent linear strains.

[0028] The device of the present invention suitable for acoustic triaxial test and its implementation method are realized as follows:

[0029] Propose a device suitable for acoustic triaxial test, such as figure 1 As shown, it is characterized in that the device includes a pressure chamber 1, a couplant storage bin 2, a permeable stone 3, a triaxial soil sample 4, a pressurized base 5, a progressive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com