Coal mine dredging equipment and coal mine dredging system

A technology for coal mines and equipment, applied in the field of sludge cleaning equipment, can solve the problems of high labor cost, low efficiency, and difficulty in manual dredging, and achieve the effect of compact structure and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

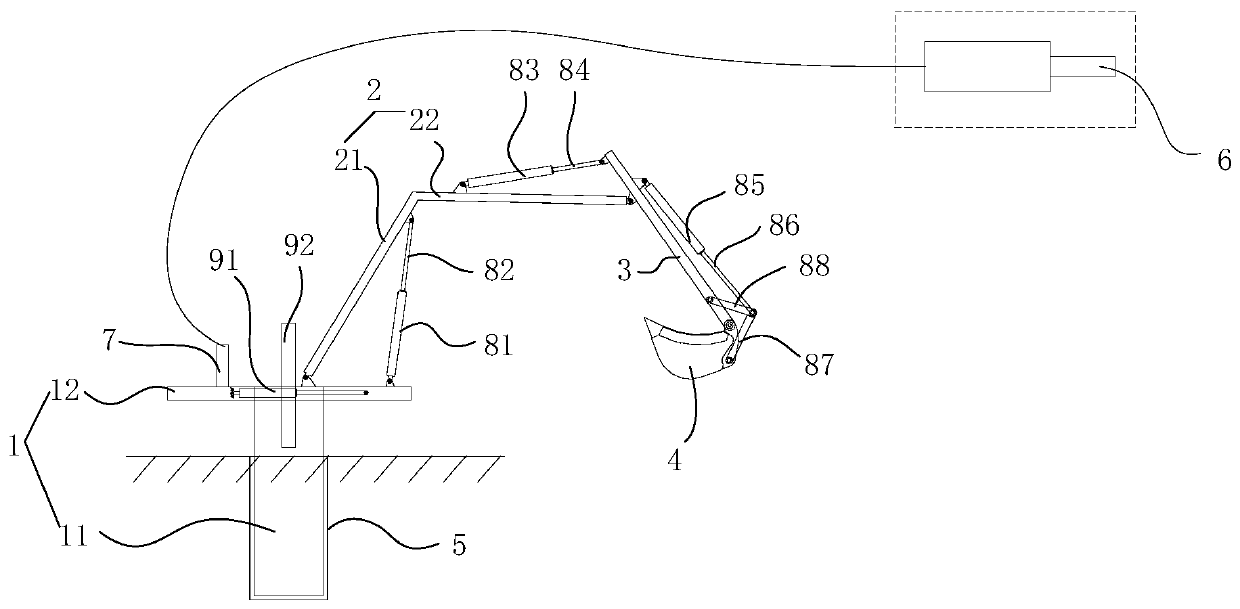

[0040] Please refer to figure 1 , this embodiment provides a coal mine dredging equipment, the coal mine dredging equipment includes a base 1 and working components.

[0041] Specifically, the lower end of the base 1 is fixed in the foundation pit 5; the working assembly includes a first mechanical arm 2, a second mechanical arm 3 and a bucket 4 that are articulated sequentially from approaching to away from the base 1; 1 is connected with a first telescopic device, the first telescopic device can drive the first mechanical arm 2 to rotate around the hinge point hinged with the base 1; between the second mechanical arm 3 and the first mechanical arm 2 is connected a second telescopic device, the second telescopic device can drive the second mechanical arm 3 to rotate around the hinge point hinged with the first mechanical arm 2; a third telescopic device is connected between the bucket 4 and the second mechanical arm 3, and the third telescopic device can Driving the bucket 4...

Embodiment 2

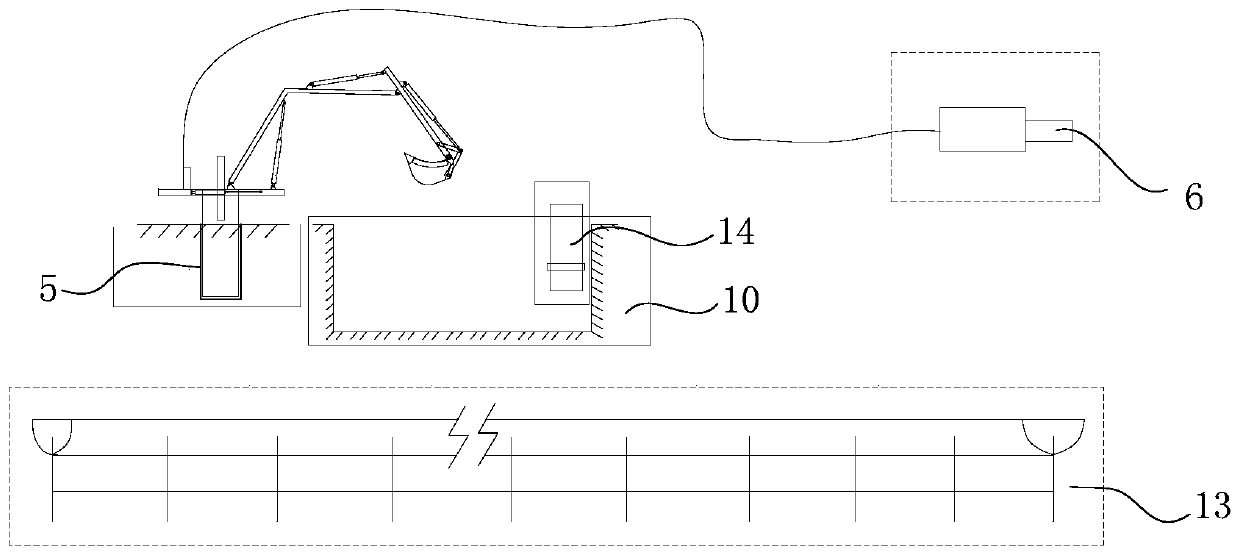

[0058] Please refer to figure 2 , combined with figure 1 , the present embodiment provides a coal mine dredging system, the coal mine dredging system is applied to coal mine roadway, including sedimentation tank 10, foundation pit 5, coal mine conveyor 13, water pump 14 and coal mine dredging equipment; wherein, the sedimentation tank 10 is connected to the flow channel of the coal mine underground roadway; the pump 14 is arranged in the sedimentation tank 10 for pumping out the accumulated water in the sedimentation tank 10; the foundation pit 5 is next to the sedimentation tank 10; the coal mine conveyor 13 is located in the coal mine underground roadway; the coal mine The dredging equipment is configured to be able to shovel out the sludge in the sedimentation tank 10 and transfer it to the coal mine conveyor 13 .

[0059] Wherein, the coal mine dredging equipment includes a base 1 and working components.

[0060] Specifically, the lower end of the base 1 is fixed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com