Ship integrated light protection armor structure

A light and armored technology, applied in the field of ships, can solve the problems of the protection function not being better played, mutual independence without taking into account the synergy, without considering the function supplement, etc., to improve the oxygen index and thermal insulation performance, reduce the base and installation space, the effect of convenient and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

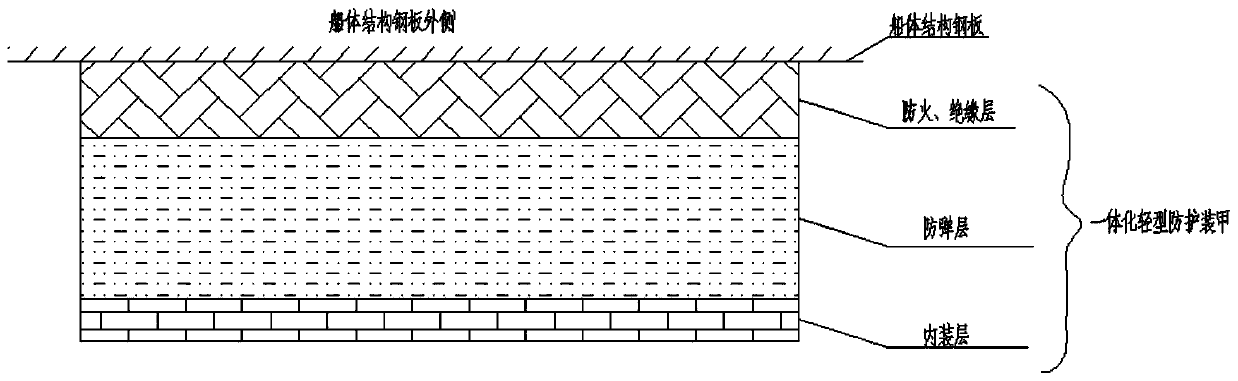

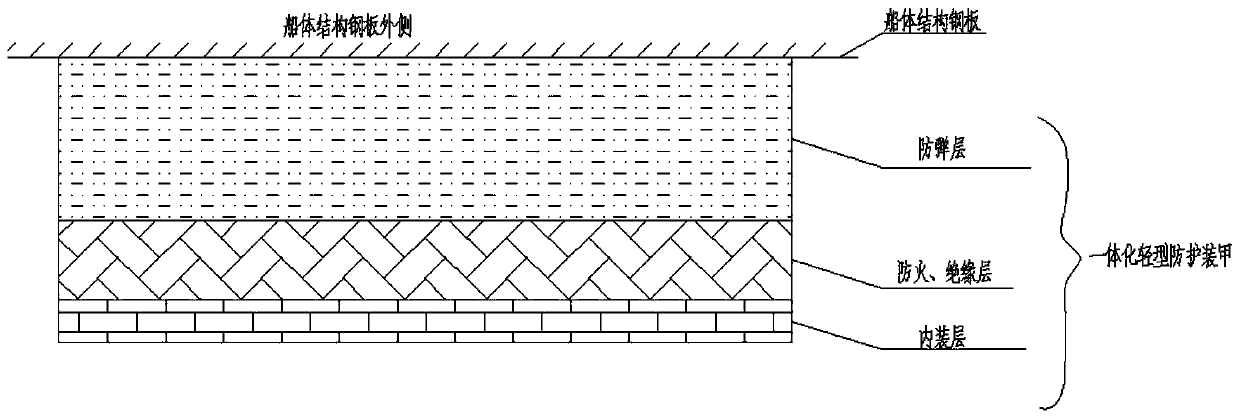

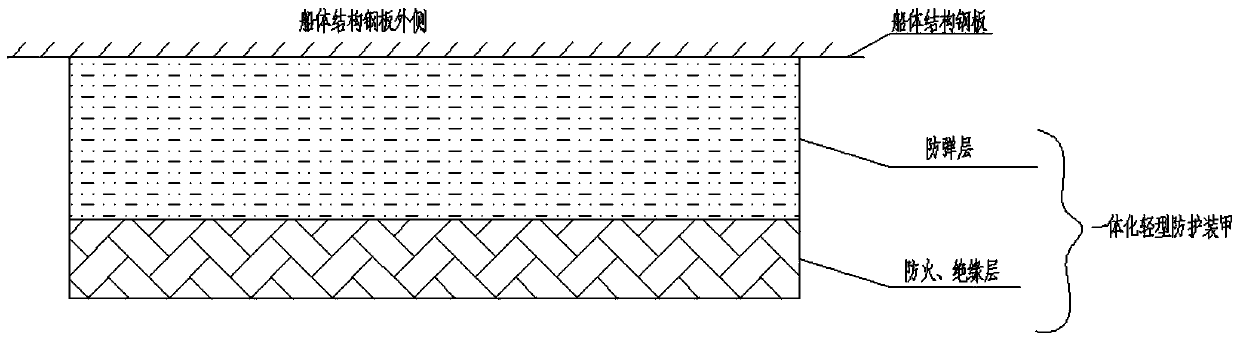

[0014] Such as figure 1 As shown, the present embodiment is a marine integrated light protective armor structure.

[0015] In the picture, the steel plate of the hull structure is 5mm DH36 hull steel, and the protection index is to defend against 95-1 type automatic rifle steel core bullets, shooting at a distance of 50m, and the fire resistance level is A30. The material of the fireproof and heat insulation layer is polycrystalline silk with a thickness of 30mm; the material of the bulletproof layer is aramid and UHMWPE fiber (PE), of which the thickness of aramid is 1mm and the thickness of PE is 22mm; the material of the inner layer is glass fiber with a thickness of 1.5mm. Layers are bonded to each other with high temperature resistant adhesive to form a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com