Balance casting filling cracking fire extinguishing bullet

A fire-fighting bomb and balance technology, applied in fire rescue and other directions, can solve problems such as lost fire-fighting opportunity, fire-fighting equipment can not be put out in time, loss, etc., to improve fire-fighting efficiency, prevent flames from spreading upwards, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further elaborate the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, Features and their functions are described in detail below.

[0026] Some embodiments of the present invention will be described in detail as follows. However, in addition to the following descriptions, the present invention can also be widely implemented in other embodiments, and the protection scope of the present invention is not limited by the embodiments, which shall prevail by the protection scope of the claims.

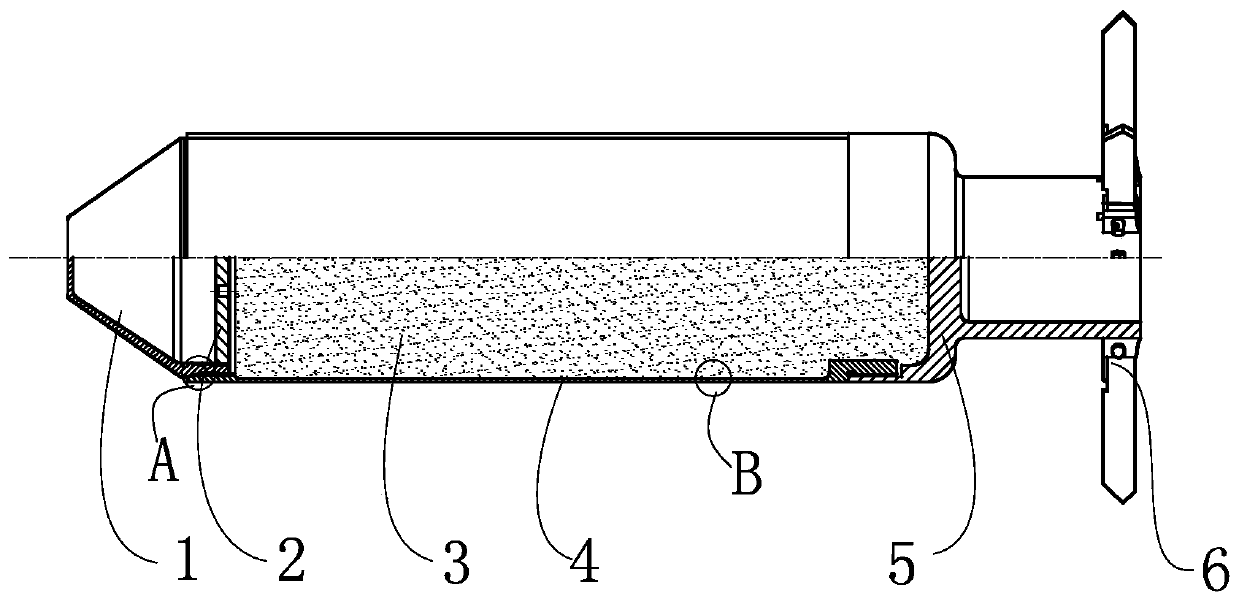

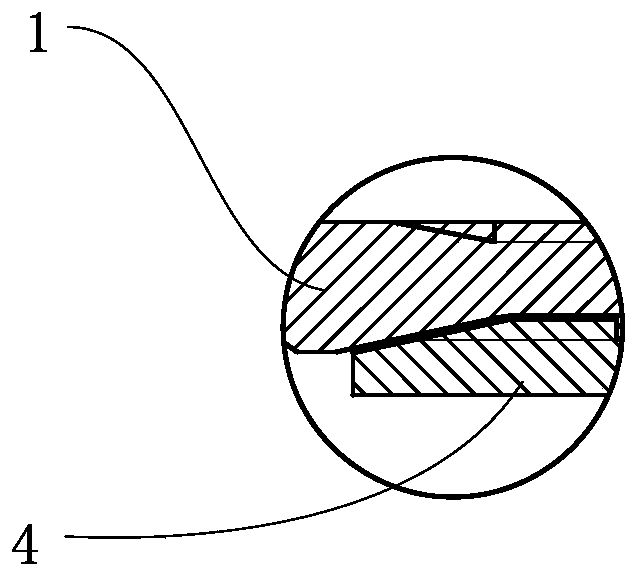

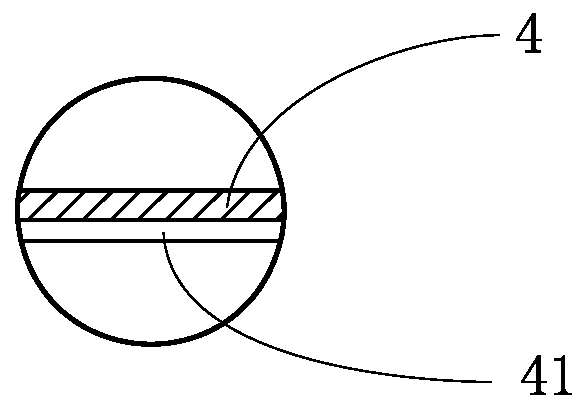

[0027] Such as figure 1 , figure 2 , image 3 The balanced projectile filling and bursting fire extinguishing bomb of the preferred embodiment of the present invention shown mainly includes: a wind cap 1, a gland 2, a fire extinguishing agent 3, a projectile body 4, a base 5, a tail 7 fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com