Sprout planting room automatic sprinkler control system

A control system and fully automatic technology, applied in germination equipment, seed and rhizome treatment, botany equipment and methods, etc., can solve the problems of large impact on seeds, difficulty in spraying, and influence on root settling, so as to avoid cold stimulation and increase Mineral content, effect of increasing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

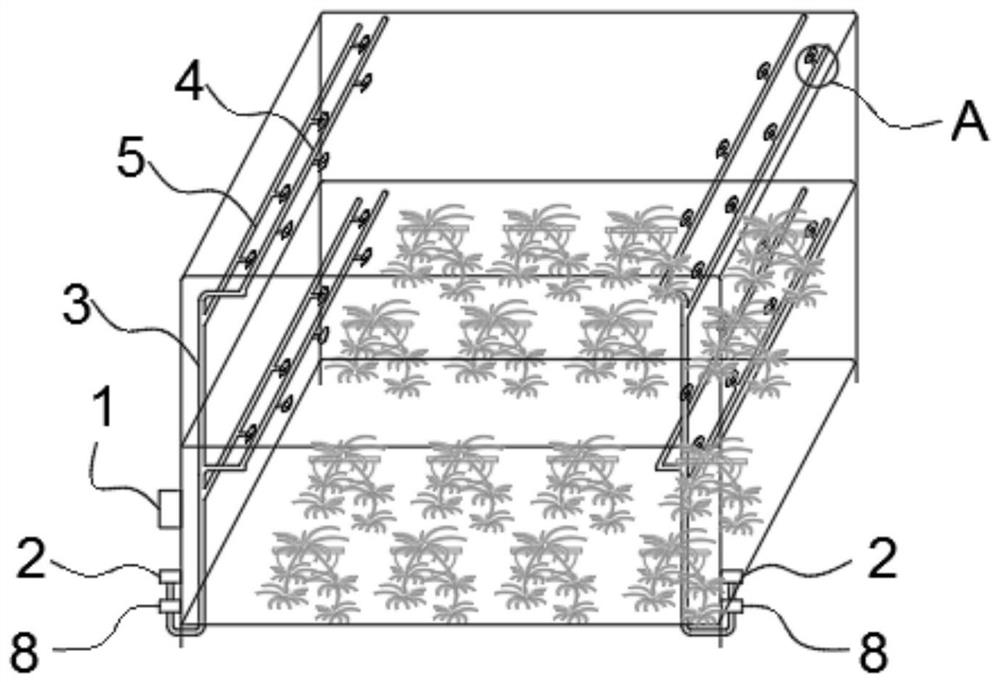

[0035] Embodiment: a kind of bean sprouts planting room automatic spraying control system, such as Figure 1-Figure 5 As shown, at least one set of spraying devices and a controller 1 are included, and each of the spraying devices includes a water supply tank 2, a main water supply pipe 3 and several sub-water supply pipes distributed at intervals along the length direction of the main water supply pipe. One end of the main water supply pipe communicates with the water supply tank, and the other end of the main water supply pipe communicates with the sub-water supply pipe, and the sub-water supply pipe includes a first branch water pipe 4 and a second branch water pipe 5. The branch water pipe and the second branch water pipe are respectively connected with nozzles 7 through nozzle branch pipes 6;

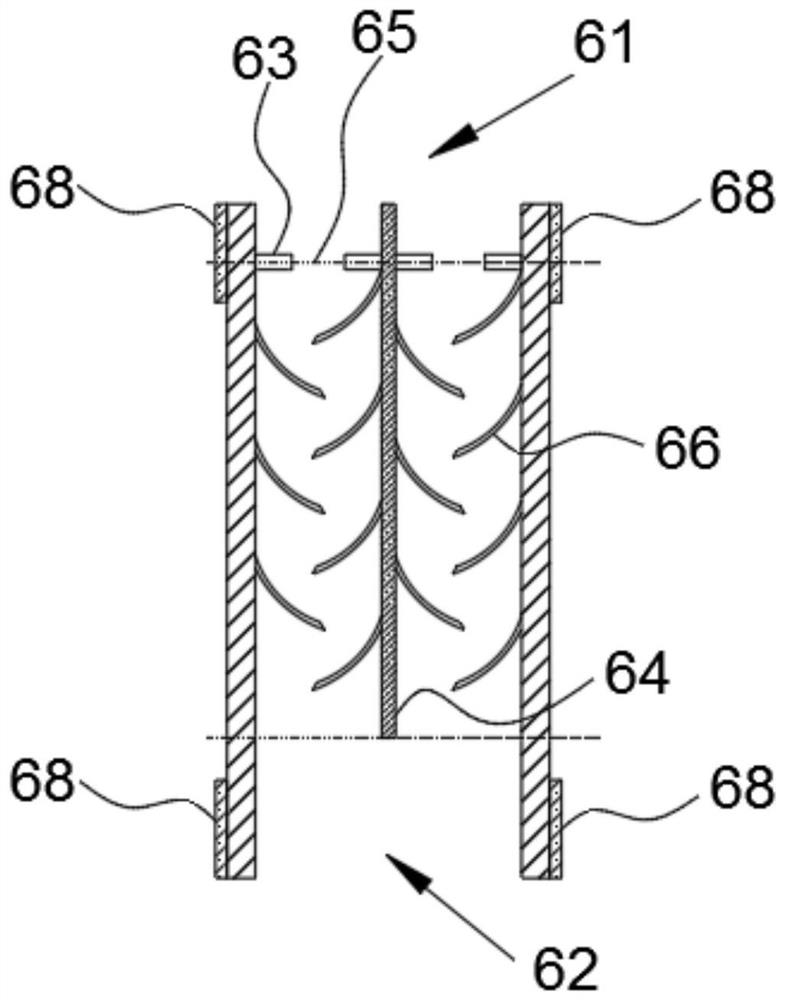

[0036] The nozzle branch pipe is a hollow circular pipe, one end of the nozzle branch pipe is provided with a water inlet 61 and the other end is provided with a water outlet 62, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com