Prefabricated part quick demolding frame and assembly line operation method thereof

A prefabricated part and demoulding technology, which is applied in the direction of manufacturing tools, ceramic molding workshops, unloading devices, etc., can solve the problems of low mold turnover frequency and spare molds, affect the appearance quality of prefabricated parts, increase manpower work time, etc., and achieve maintenance and repair The effect of low cost, sufficient market resources, and good control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

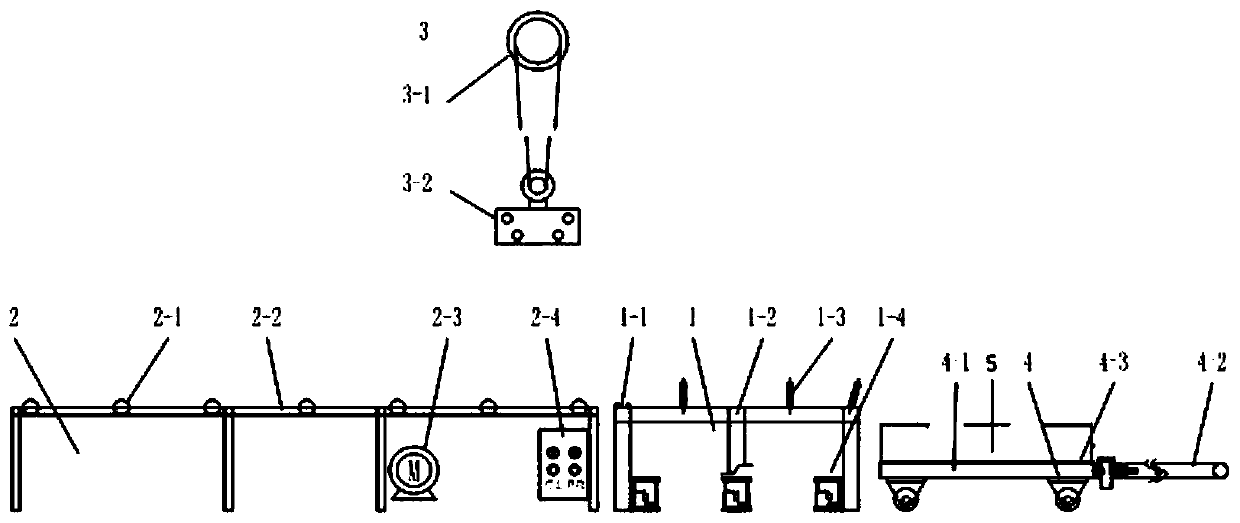

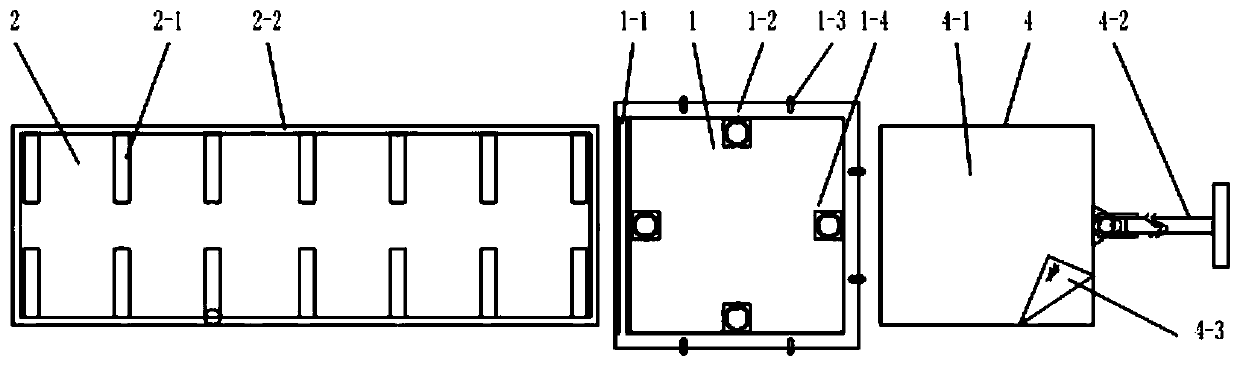

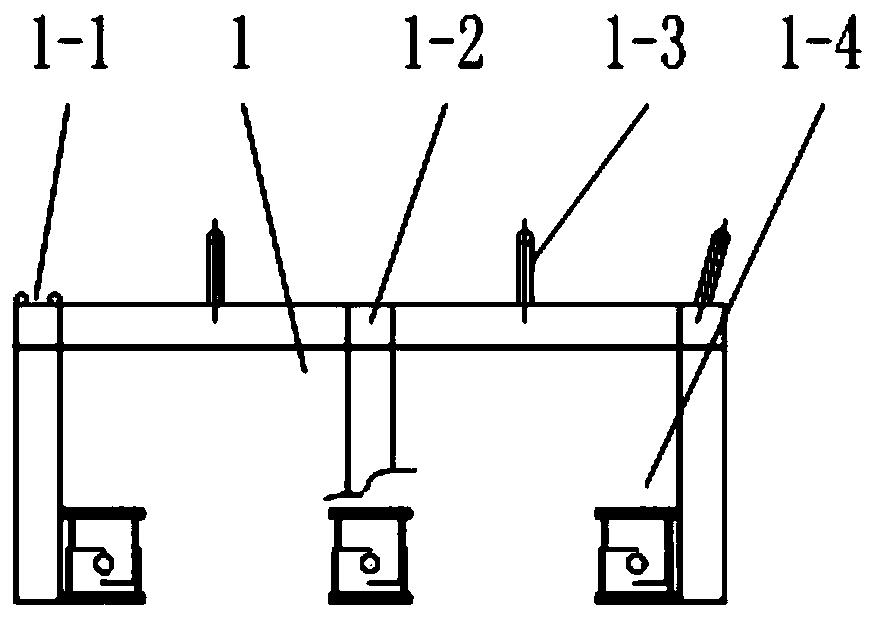

[0031] like Figure 1-5 The shown prefabricated part rapid demoulding frame and assembly line operation method include four parts: rapid demoulding frame 1, prefabricated part belt mold conveyor 2, turning spreader 3 and prefabricated part transport flat car 4. The quick demoulding frame 1 is composed of a mold slot 1-1, a support frame 1-2, a guide pin 1-3, a plug-type telescopic sleeve 1-4 and other components. The preform belt mold conveyor 2 is used to transport the preform to be demoulded to the side of the quick demoulding frame 1, including a roller set 2-1, a bracket 2-2, a drive motor 2-3 and a controller 2-4 and other components. The turning hanger 3 is installed directly above the end of the prefabricated part belt mold conveyor 2 close to the quick demoulding frame 1, and can move longitudinally or laterally along the prefabricated part belt mold conveyor 2 and the quick demoulding frame 1 within a certain range, including Electric or manual hoist 3-1, grabbing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com