Oil well layered yield splitting method based on dynamic and static coupling

A technology of dynamic and static coupling and output, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as poor adaptability and large amount of calculation, and achieve the effect of solving poor adaptability, saving work time, and the method is reasonable and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing:

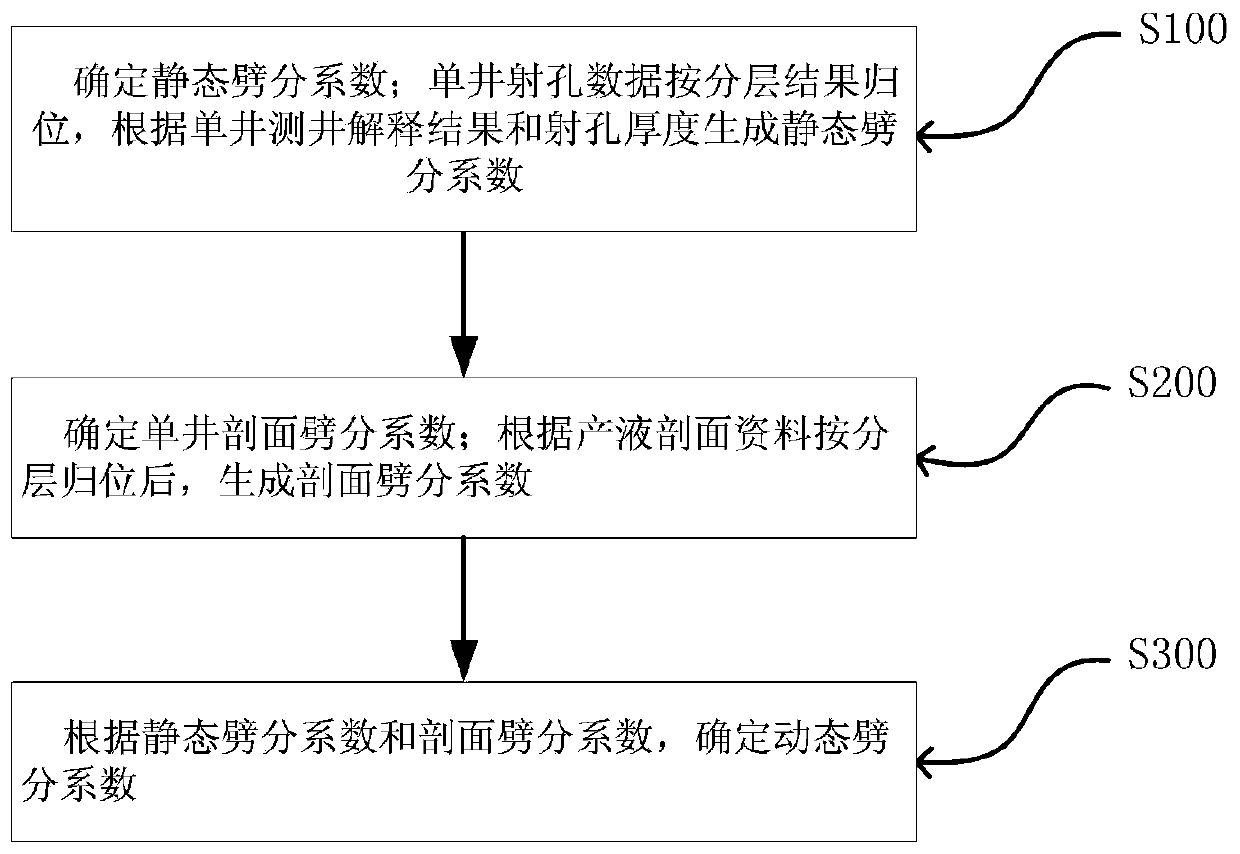

[0048] Such as figure 1 As shown, the method for splitting oil well layered production based on dynamic and static coupling described in the embodiment of the present invention includes the following steps:

[0049] S100. Determine the static splitting coefficient;

[0050] The single well perforation data is homing according to the layered results, and the static splitting coefficient is generated according to the single well logging interpretation results and perforation thickness;

[0051] S200, determining the splitting coefficient of the single well profile;

[0052] According to the profile data of liquid production, the profile splitting coefficient is generated after homing in layers;

[0053] S300. Determine a dynamic splitting coefficient according to the static splitting coefficient and the profile splitting coefficient.

[0054] details as follows:

[0055] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com