Buckling profile

A buckle profile and buckle technology, which is applied in the direction of connecting components, mechanical equipment, friction clamped detachable fasteners, etc., can solve the problem of insufficient fastening, general buckle effect of buckle profiles, difficulty in meeting construction requirements, etc. problem, to achieve the effect of convenient installation, good buckle effect and firm installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

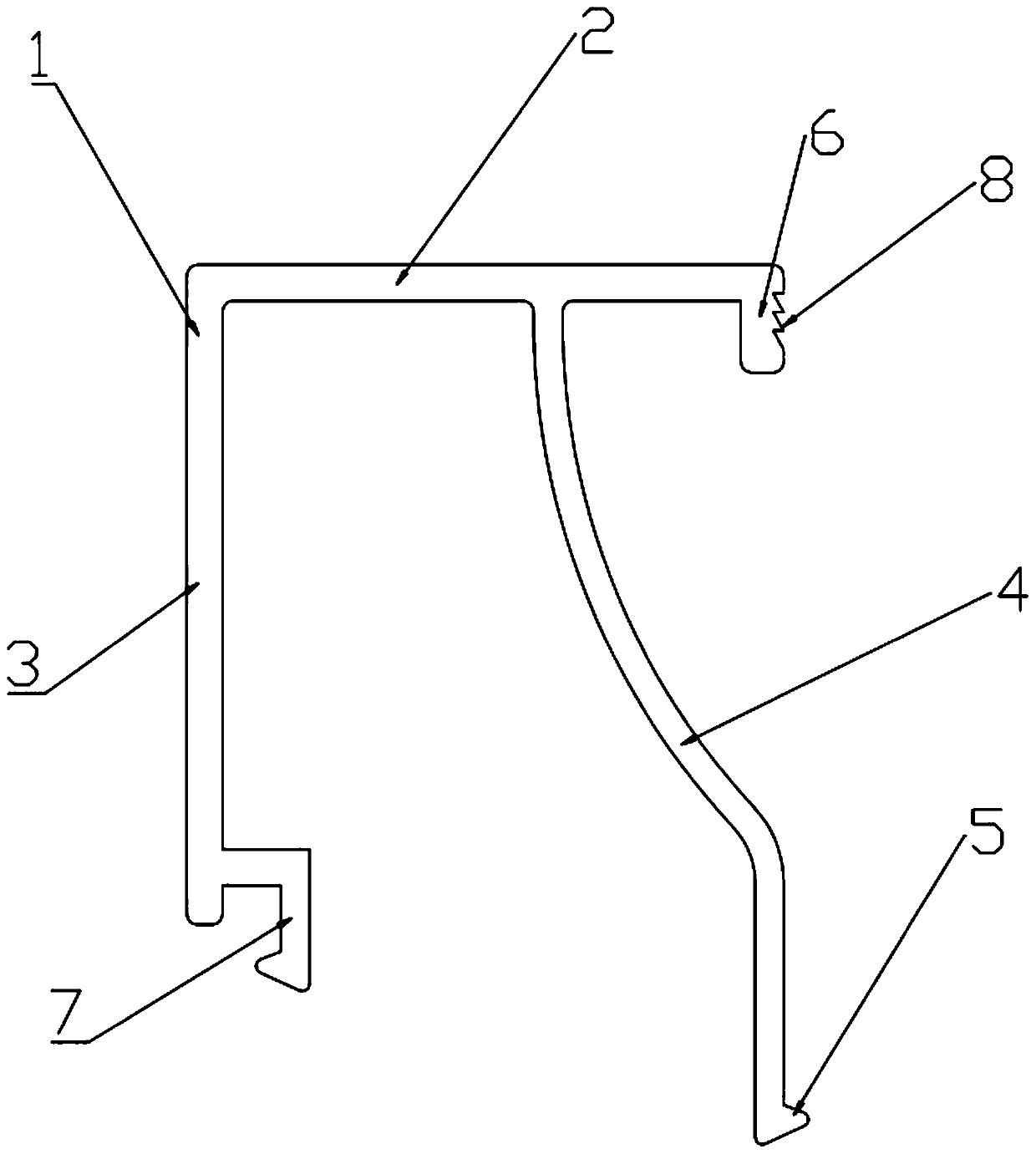

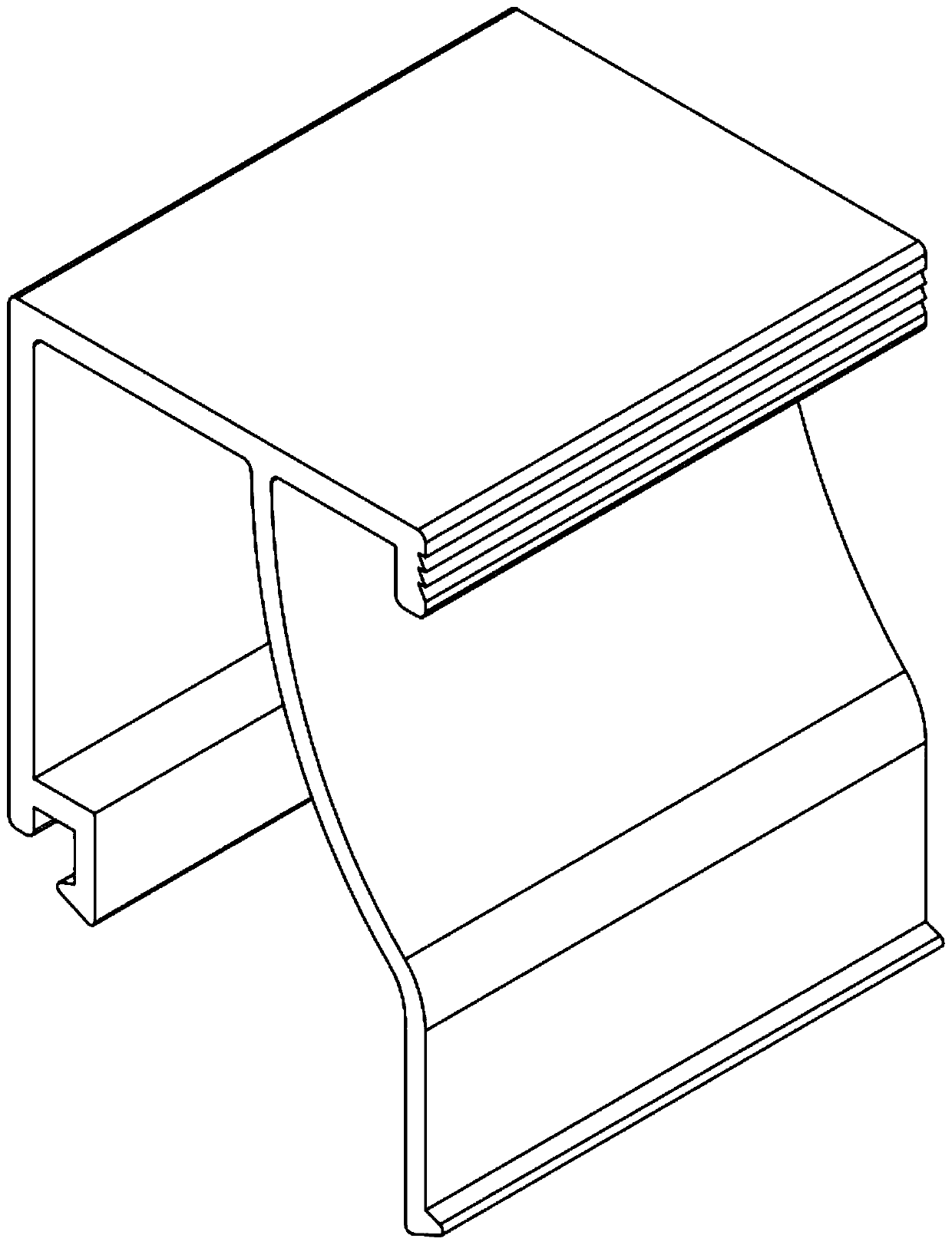

[0011] With reference to the accompanying drawings, a buckle profile includes an L-shaped frame 1, the L-shaped frame 1 is composed of a horizontal plate 2 and a vertical plate 3, and an outward buckle piece 4 is provided under the horizontal plate 2. The end of the outward buckle piece 4 away from the horizontal plate 2 is provided with an outward buckle head 5, the intersection of the horizontal plate 2 and the vertical plate 3 is rounded, and the horizontal plate 2 is far away from the intersection. The end of the intersection is provided with a downwardly disposed vertical baffle 6, and the end of the vertical plate 3 away from the intersection is provided with an inward buckle 7.

[0012] As a preferred solution, the vertical baffle 6 is provided with anti-slip lines 8 .

[0013] Compared with the prior art, the present invention has the advantages of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com