Processing equipment based on plastic recycling

A technology for processing equipment and plastics, which is applied in the direction of plastic recycling, recycling technology, mechanical material recycling, etc. It can solve problems such as littering, reduce the efficiency of recycling waste plastics, and the effect of recycling waste plastics is not good, and achieve recycling Use the effect of working convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

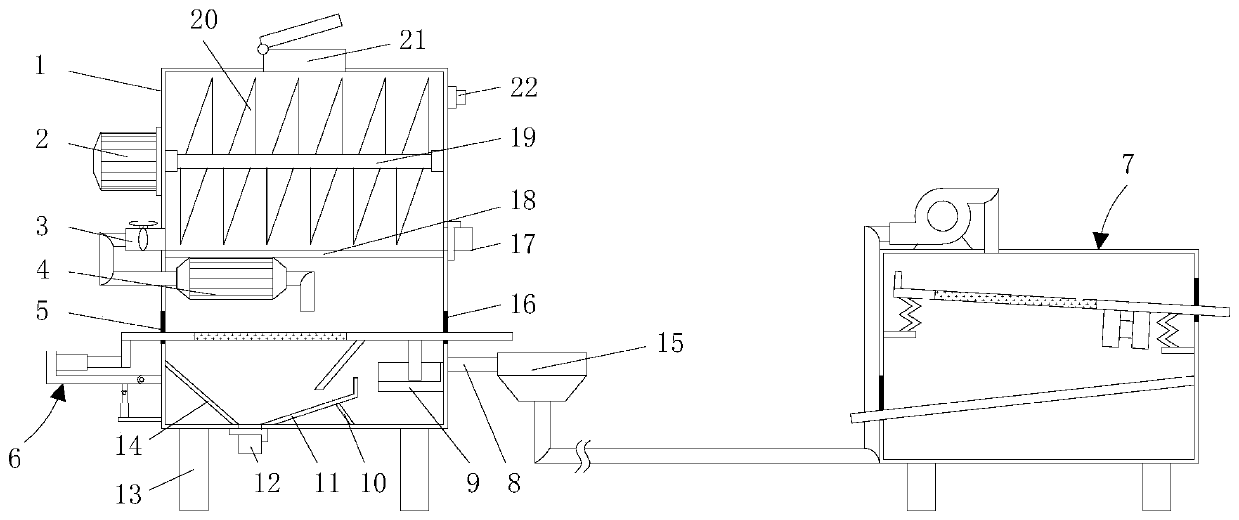

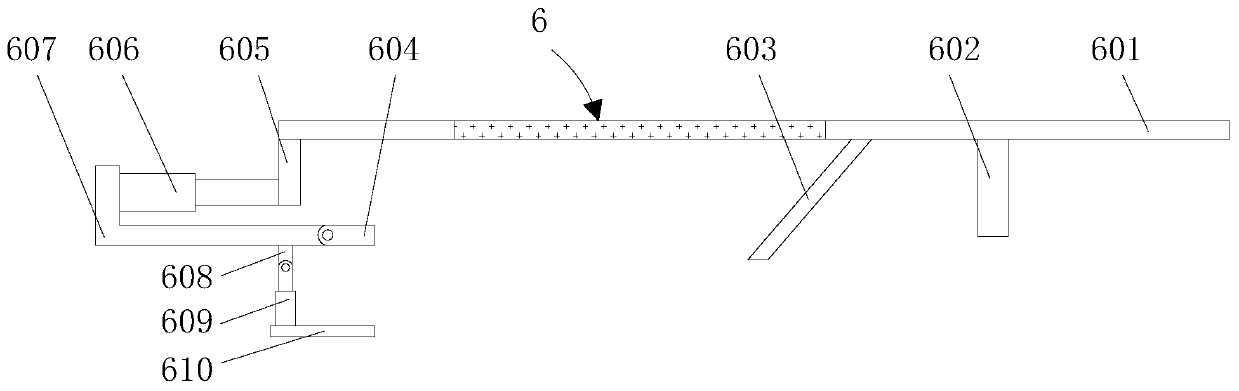

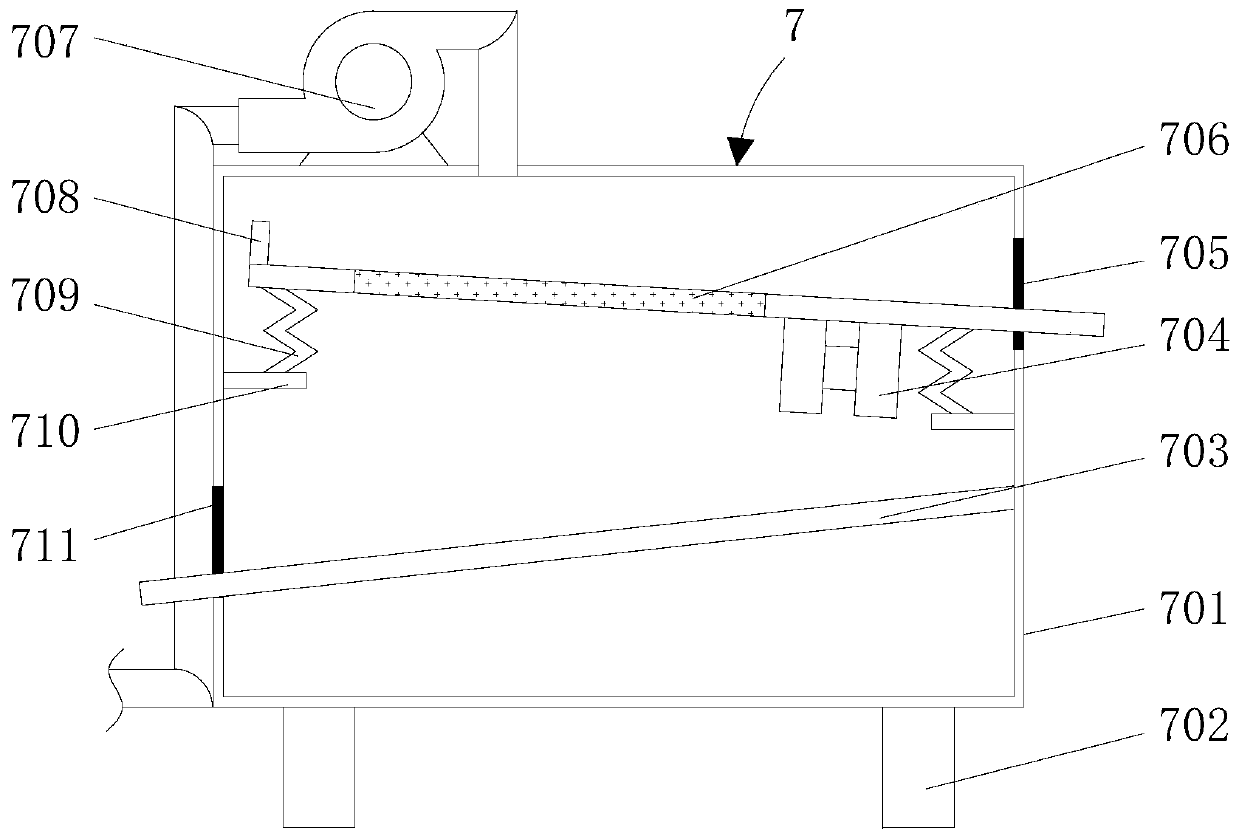

[0023] see Figure 1-6, a treatment device based on plastic recycling, including a first box body 1, a first-stage screening mechanism 6 and a second-stage screening mechanism 7, the middle end of the top of the first box body 1 is provided with a feed inlet 21, and the inlet The left end of the top of the material opening 21 is movably connected with a cover plate through a hinge, and the upper end on the right side of the first box body 1 is fixedly connected with a controller 22, and the two terminals of the controller 22 are connected with a power plug through wires, and the controller 22 The outer surface of the front to back is fixedly connected with the crushing motor switch 221, the vibration motor switch 222, the first fan switch 223, the second fan switch 224, the first telescopic control button 225 and the second telescopic control button 226, the first box body 1 and the top of the partition 18 is provided with a second discharge port 17, the inner surface of the f...

Embodiment 2

[0025] see Figure 1-6, a treatment device based on plastic recycling, including a first box body 1, a first-stage screening mechanism 6 and a second-stage screening mechanism 7, the middle end of the top of the first box body 1 is provided with a feed inlet 21, and the inlet The left end of the top of the material opening 21 is movably connected with a cover plate through a hinge, and the upper end on the right side of the first box body 1 is fixedly connected with a controller 22, and the two terminals of the controller 22 are connected with a power plug through wires, and the controller 22 The outer surface of the front to back is fixedly connected with the crushing motor switch 221, the vibration motor switch 222, the first fan switch 223, the second fan switch 224, the first telescopic control button 225 and the second telescopic control button 226, the first box body 1 and the top of the partition 18 is provided with a second discharge port 17, the inner surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com