A fast-assembled energy-dissipative infill wall panel

A technology for filling walls and wall panels, applied in the field of filling wall panels, can solve the problems of complex production and construction technology and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

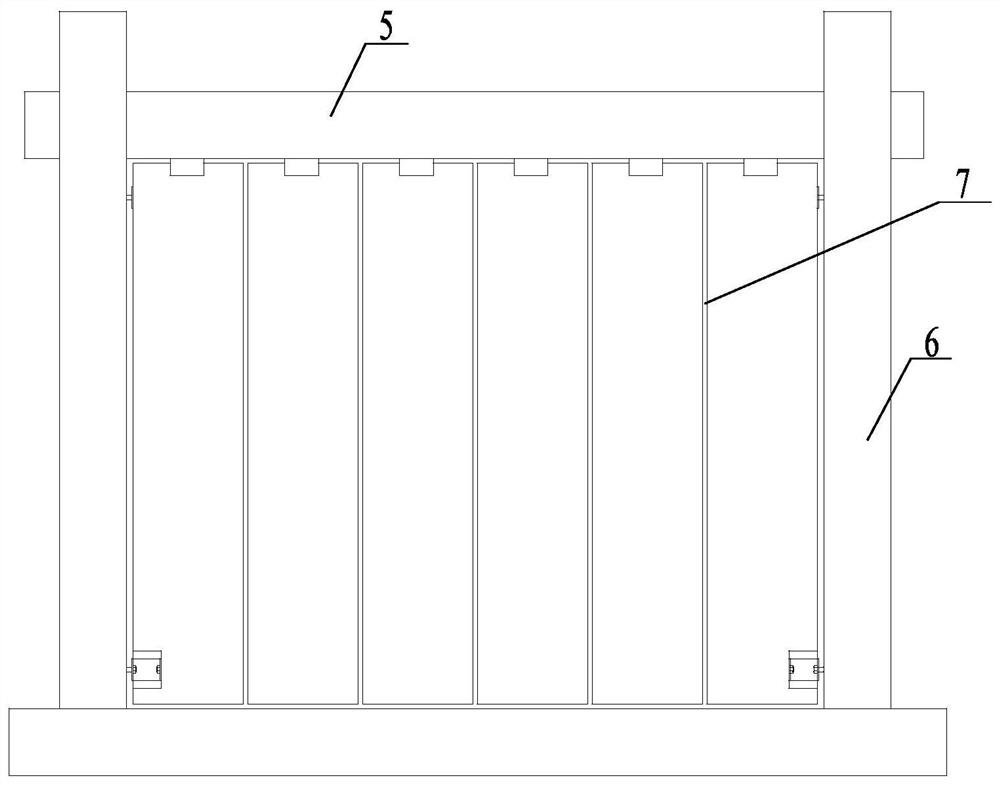

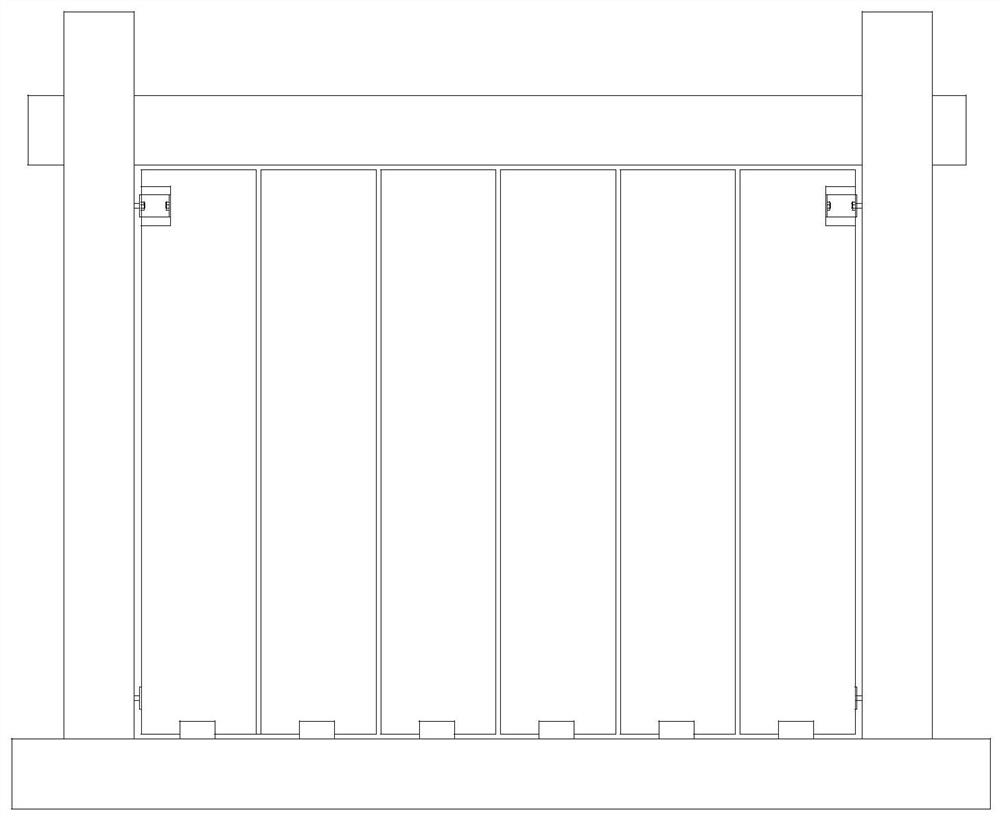

[0034] The present invention proposes a fast-assembled energy-dissipating filling wallboard. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

[0035] combine Figure 3 to Figure 9 As shown in the present invention, a fast-assembled energy-dissipating filling wallboard includes a first wallboard group at the end and a second wallboard group at the middle, wherein the first wallboard group at the end has two The two sides of the group are connected to the frame column, and the first wall panel group and the second wall panel group and the adjacent second wall panel groups are connected through the mutual cooperation of the tenon and the tenon. Specifically: a tenon / tenon is provided on the other side of the first wallboard group (away from the frame column), and a tenon / tenon is provided correspondingly on one side of the second wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com