Marking ink with strong adhesion, preparation method thereof and marking pen with strong adhesion

A technology of adhesion and marking pens, applied to other ink pens, inks, printing, etc., can solve the problems of poor adhesion fastness and achieve the effect of not being easy to absorb ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

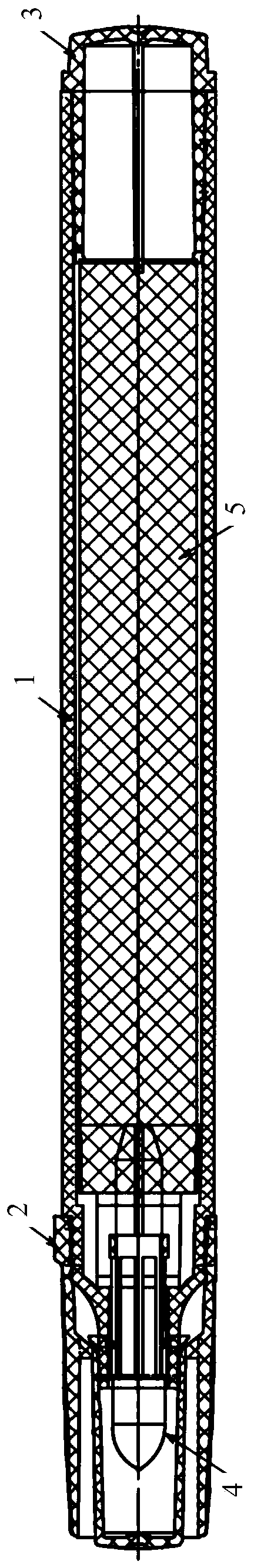

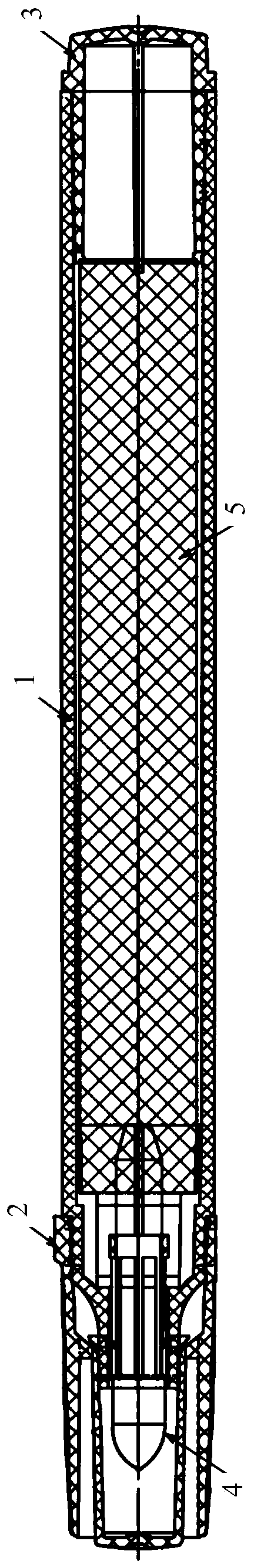

Image

Examples

Embodiment 1

[0086] Add 35 parts by weight of ethanol, 30 parts by weight of ethylene glycol-methyl ether and 10 parts by weight of direct black ASF600 dyestuff into a reaction kettle with stirring equipment (stirring speed is 400rpm), and obtain a uniform solution after stirring for 2 hours. Add 12 parts by weight of alcohol-soluble dimer acid polyamide resin and 10 parts by weight of alkyd resin, and finally add 0.5 parts by weight of n-propanol and 0.5 parts by weight of adipate and heat to 40-60 ° C, keep stirring for 4 A homogeneous solution was obtained after 1 hour, and a strong adhesive marking ink was obtained after filtration.

Embodiment 2

[0088] Add 35 parts by weight of ethanol, 30 parts by weight of ethylene glycol-methyl ether and 10 parts by weight of solvent blue 58 dye into a reactor equipped with a stirring device (stirring speed: 400 rpm), and stir for 2 hours to obtain a uniform solution. Add 13 parts by weight of alcohol-soluble dimer acid polyamide resin and 9 parts by weight of alkyd resin under stirring, and finally add 0.5 parts by weight of n-propanol and 0.5 parts by weight of adipate and heat to 40-60 ° C, After heat preservation and stirring for 4 hours, a uniform solution was obtained, and after filtration, a marking ink with strong adhesion was obtained.

Embodiment 3

[0090] Add 35 parts by weight of ethanol, 30 parts by weight of ethylene glycol-methyl ether and 10 parts by weight of Direct Red 4GE dye into a reactor equipped with a stirring device (stirring speed: 400 rpm), and stir for 2 hours to obtain a uniform solution. Add 14 parts by weight of alcohol-soluble dimer acid polyamide resin and 8 parts by weight of alkyd resin under stirring, and finally add 0.5 parts by weight of n-propanol and 0.5 parts by weight of adipate and heat to 40-60 ° C, After heat preservation and stirring for 4 hours, a uniform solution was obtained, and after filtration, a marking ink with strong adhesion was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com