Magnetic latching relay

A technology of magnetic latching relays and magnetic steel, applied in electromagnetic relays, relays, non-polar relays, etc., can solve problems such as increased coil power, smaller coil space, and increased difficulty in production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

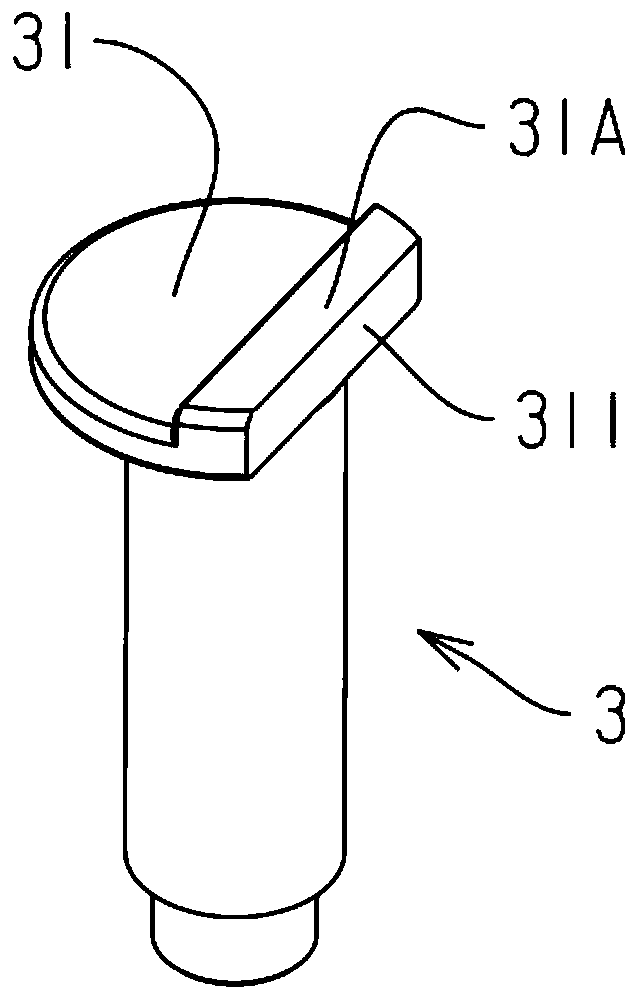

[0031] Embodiment: a kind of magnetic latching relay, such as figure 1 Shown: includes a yoke 1, an armature 2 and an iron core 3, the armature and the yoke are elastically connected through a reed 4, the iron core is wound with a coil (not shown in the figure), the iron core The suction end has a pole piece 31, such as figure 2 and image 3 As shown: the upper surface of the pole shoe has a protrusion 31A or a groove 31B, and the height difference between the iron core and the armature is adjusted by the height difference between the protrusion or the groove and the upper surface of the pole shoe. The gap between the magnetic circuits, so as to achieve the balance of the attractive force of the magnetic circuit on the armature and the reset force (actually adjust the set voltage and reset voltage).

[0032] There is a cutout 311 on one side of the pole shoe, through which the attraction force of the iron core to the armature is adjusted before and after attraction;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com