Three-phase motor drive protection circuit

A technology for driving protection circuits and three-phase motors, applied in emergency protection circuit devices, electrical components, etc., can solve the problems of high cost of FPGA chips, increased control difficulty, and need for programming intervention, achieving low cost, simple and fast control process, Avoid the effect of frequent restarts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

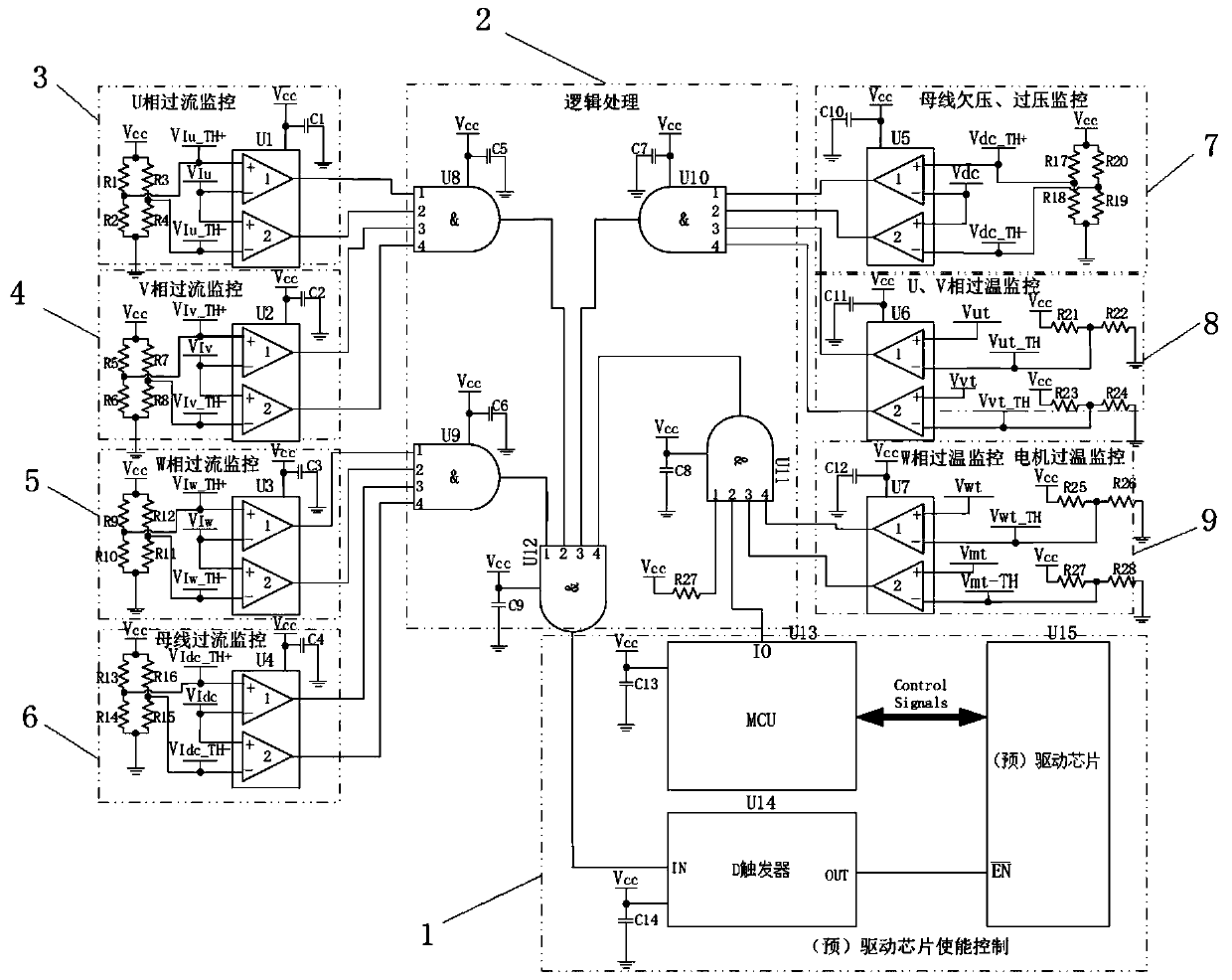

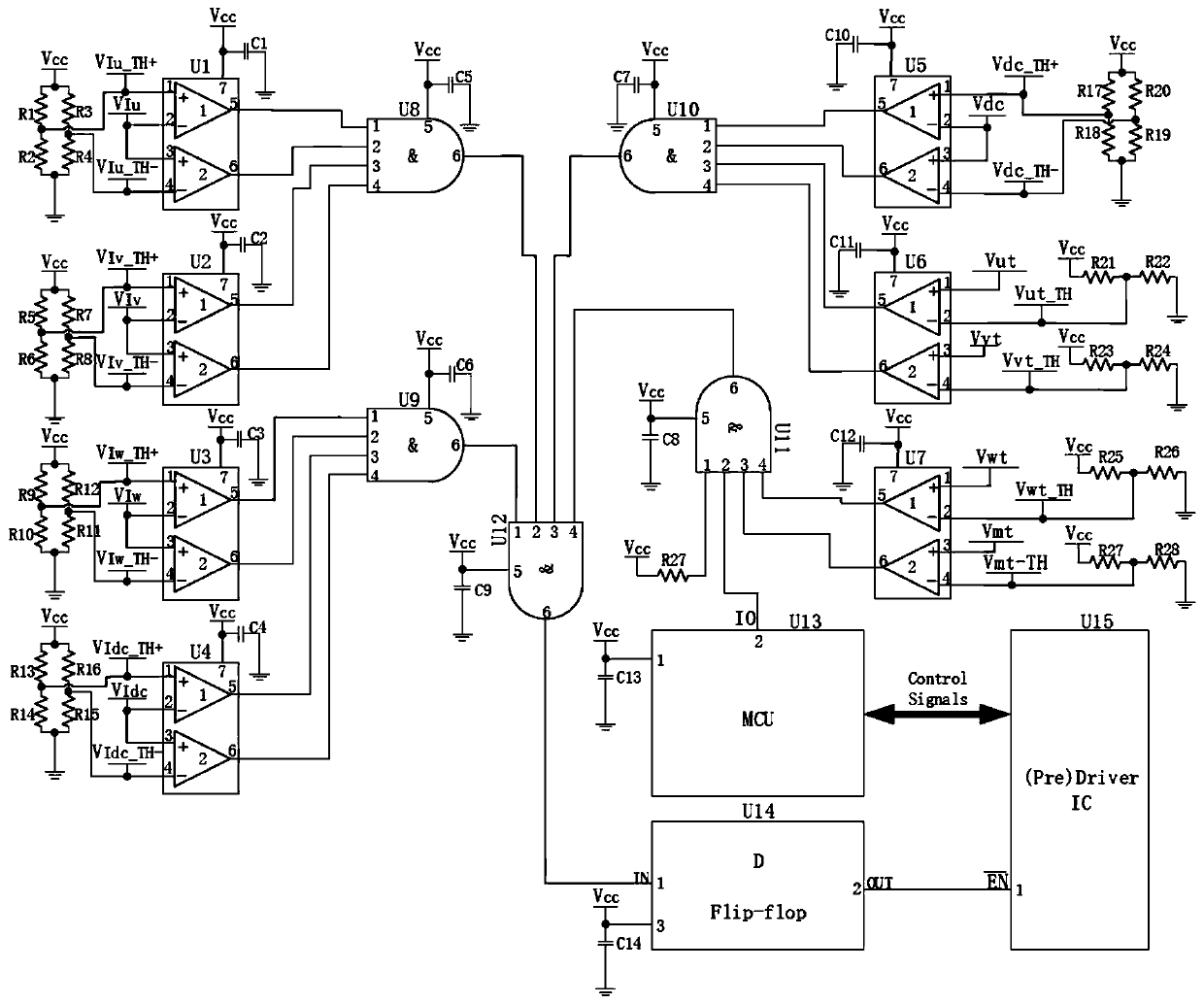

[0054] Such as figure 2 As shown, in this embodiment, the U-phase current sensor of the motor outputs V Iu Connect to port 2 and port 3 of the first 2-channel comparator U1, respectively. U phase current positive overcurrent protection threshold V Iu_TH+ It is connected to the first port of U1, which is generated by voltage division of VCC through the first resistor R1 and the second resistor R2, wherein VCC is connected to R1, and R1 is connected to ground through R2. U phase current negative overcurrent protection threshold V Iu_TH- It is connected to the fourth port of U1, which is generated by voltage division of VCC through the third resistor R3 and the fourth resistor R4, wherein VCC is connected to R3, and R3 is connected to ground through R4. The seventh port of U1 is connected to VCC, and connected to ground through the first capacitor C1. The fifth port and the sixth port of U1 are respectively connected to the first port and the second port of the second 4-inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com