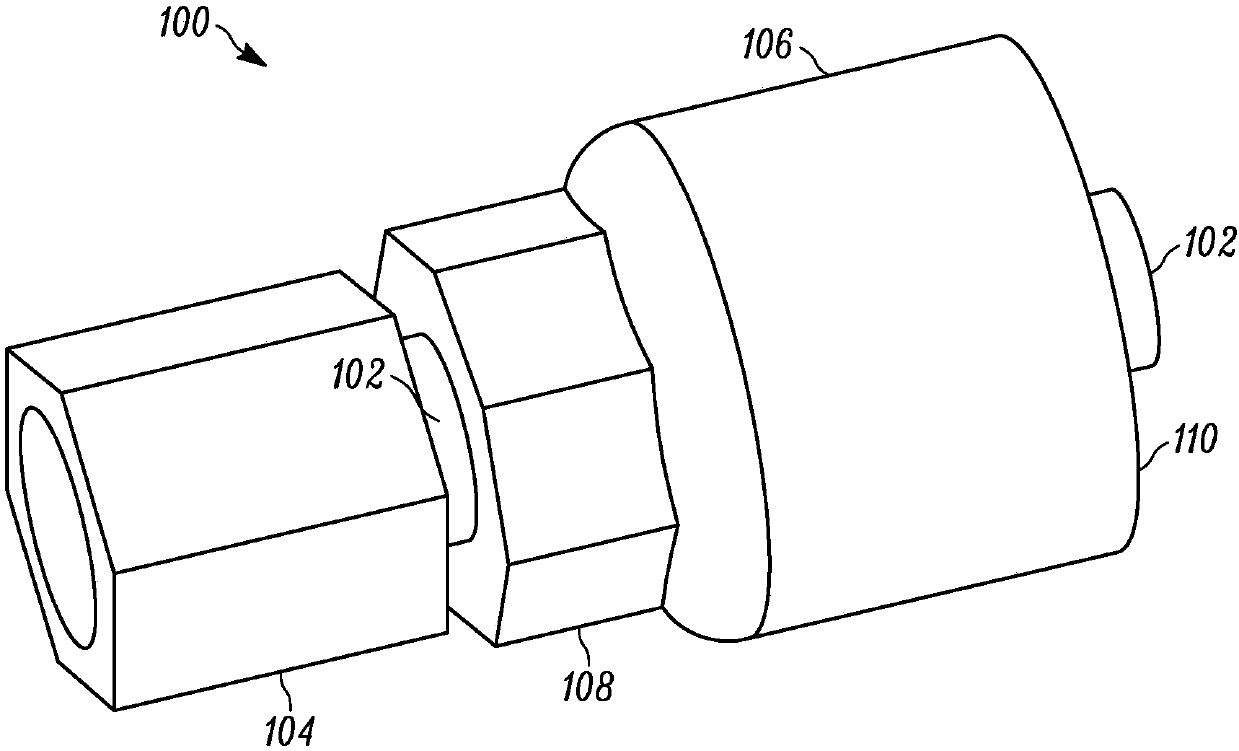

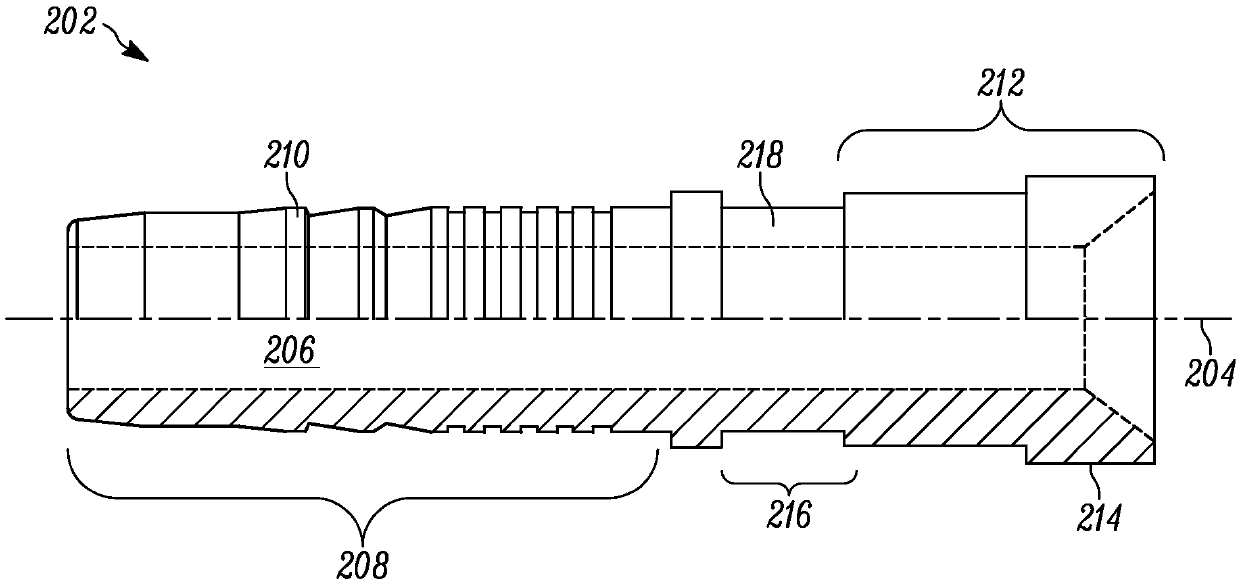

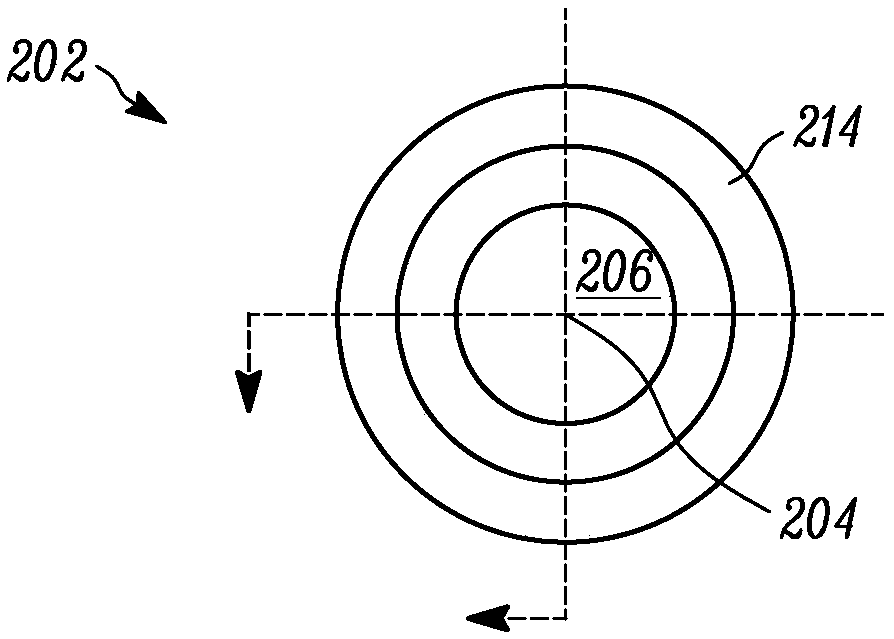

Eight sided forged ferrule staking crimped fitting and method of manufacture thereof

A technology for ferrules and fittings, applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, through components, etc., which can solve the problems of leakage at brazing joints and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description of variants is merely illustrative in nature and is in no way intended to limit the scope, application or use of the disclosure. The description presented herein is only for the purpose of illustrating various embodiments of the disclosure and should not be construed as limiting the scope and applicability of the disclosure. In the Summary of the Disclosure and this Detailed Description, each numerical value should be read once as modified by the term "about" (unless it has expressly been so modified), and then again as if not so modified Read unless the context indicates otherwise. Furthermore, in the Summary of the Disclosure and this Detailed Description, it is to be understood that ranges of values listed or described as useful, suitable, etc., are intended to be that all values within the range, including endpoints, are considered to have been stated . For example, "range from 1 to 10" will be read to indicate every possible number a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com