L-shaped open type permanent beam template

A permanent, open-type technology, applied in joists, girders, trusses, etc., can solve the problems of restricting the promotion and application of ECC permanent formwork, taking up a lot of space, high transportation costs, etc., and achieving excellent deformation ability and crack control ability. , The effect of reducing transportation costs and reducing construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

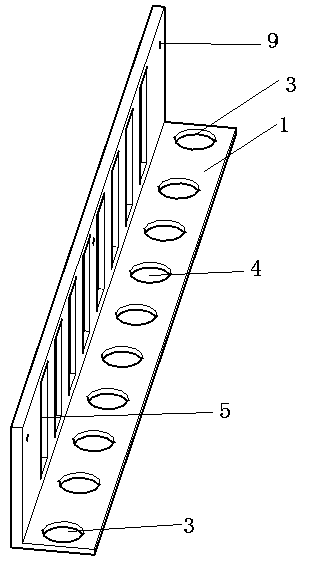

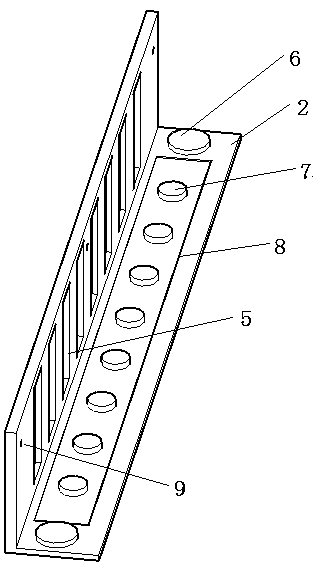

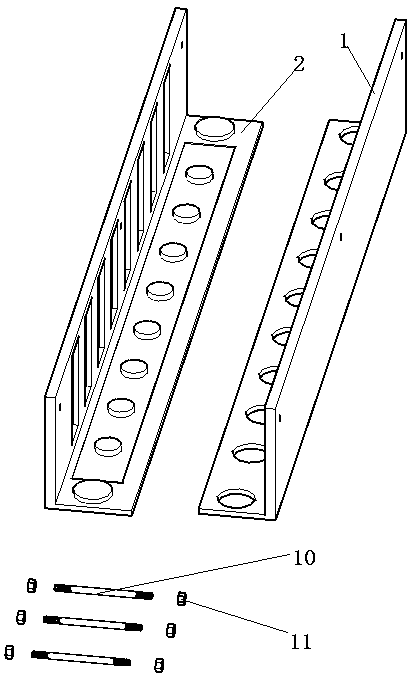

[0033] Such as Figure 1-4 As shown, the L-shaped open-type permanent beam formwork of this embodiment includes an L-shaped upper formwork body 1 and an L-shaped lower formwork body 2, and the two ends of the bottom surface of the L-shaped upper formwork body 1 are provided with limiting holes 3. The bottom surface of the L-shaped lower formwork body 2 is provided with a limit key 6 cooperating with the limit hole 3, and a group of occlusal holes 4 are arranged in the middle of the bottom surface of the L-shaped upper formwork body, and the bottom surface of the L-shaped lower formwork body A group of snapping keys 7 matched with the snapping hole 4 is arranged in the middle of the center, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com