Automatic walking tunnel trestle capable of steering through rotating shaft as well as method

A technology of automatic walking and rotating shaft, applied in the direction of pedestrian overpass, bridge, bridge form, etc., to achieve the effect of convenient operation, easy promotion, and increased equipment flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

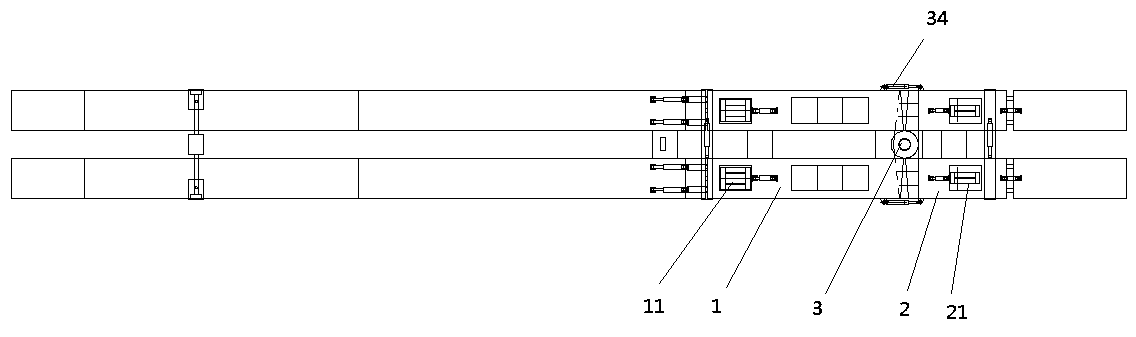

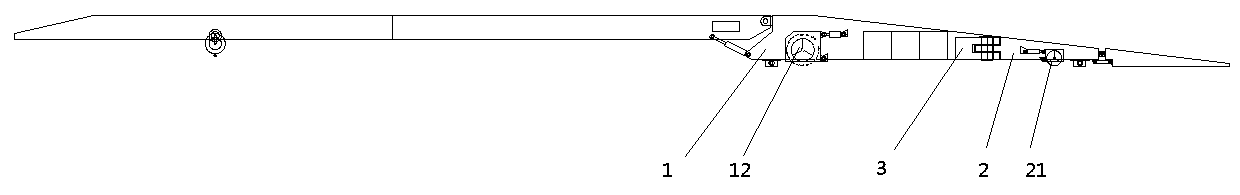

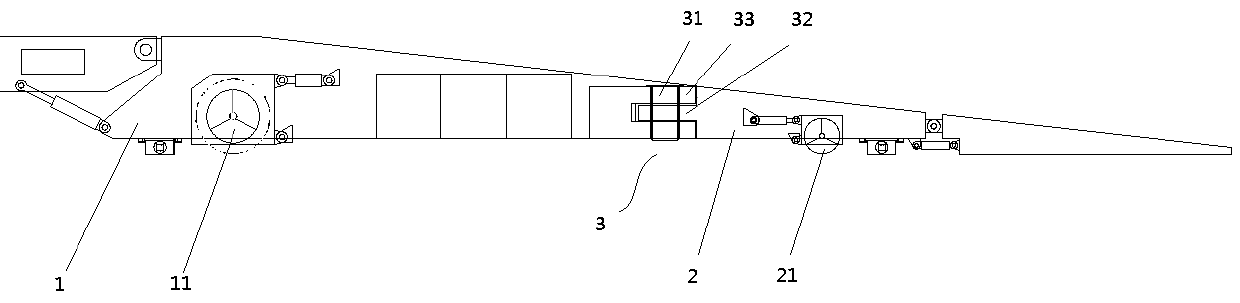

[0017] Attached below Figures 1 to 5 The preferred embodiment of the present invention is further described, including the rear main body 2 connected with the front main body 1 through the large rotating shaft device 3, which together constitute the upward slope of the vehicle; Walking wheel 21;

[0018] The large rotating shaft device 3 includes a boss structure 32 and a concave platform structure 33 connected by a pin shaft 31, and a rotary power mechanism 34;

[0019] The boss structure 32 is arranged at the connecting end of the rear body 2, and the concave platform structure 33 is arranged at the connecting end of the front body 1, the boss structure 32 is inserted in the concave platform structure 33, and the pin shaft 31 is inserted in the In the through hole 35 of the rotating shaft of the convex platform structure 32 and the concave platform structure 33; the rear main body 2 rotates around the pin shaft 31 relative to the front main body 1; The front main body 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com