Stacked packaging case lifting device

A technology for packing boxes and suitcases, which is applied in the direction of lifting devices, lifting frames, etc., which can solve the problems of inconvenient operation, high overall cost, and shortened service life of guide posts, and achieve the effects of prolonging service life, low overall cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

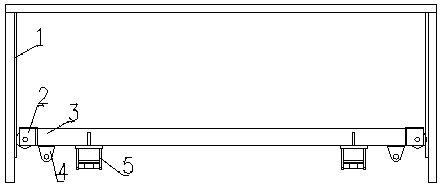

[0020] Accompanying drawing is a kind of specific embodiment of the present invention.

[0021] The lifting device for stacked packing boxes of the present invention includes a carrying case beam 3 and a bracket, and is characterized in that: rollers 2 are arranged on the tops of both ends of the carrying case cross beam 3, and an oil cylinder upper seat 4 is respectively fixed on the lower sides of the two ends of the carrying case cross beam 3. The inboard of the upper seat 4 of the oil cylinder is also respectively provided with a suitcase hanging plate 5; The suitcase hanging plate 5 is composed of a suitcase brace 6, a suitcase flap 8 and a tension spring 7, the suitcase brace 6 is movably connected with the suitcase flap 8, and the suitcase brace 6 and the suitcase flap 8 are provided with a spring Draw the hole, and the tension spring 7 is connected with the tension of the two draw holes. A reinforcing rib 9 is also fixed between the suitcase hanging board 5 and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com