Multi-band saw with adjustable cutting thickness and working method thereof

A technology for cutting thickness and band sawing, which is applied in the direction of band saws, sawing equipment, manufacturing tools, etc. It can solve the problems of complicated operation, low efficiency, time-consuming and laborious, etc., and achieve the effect of simple operation, guaranteed processing progress, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

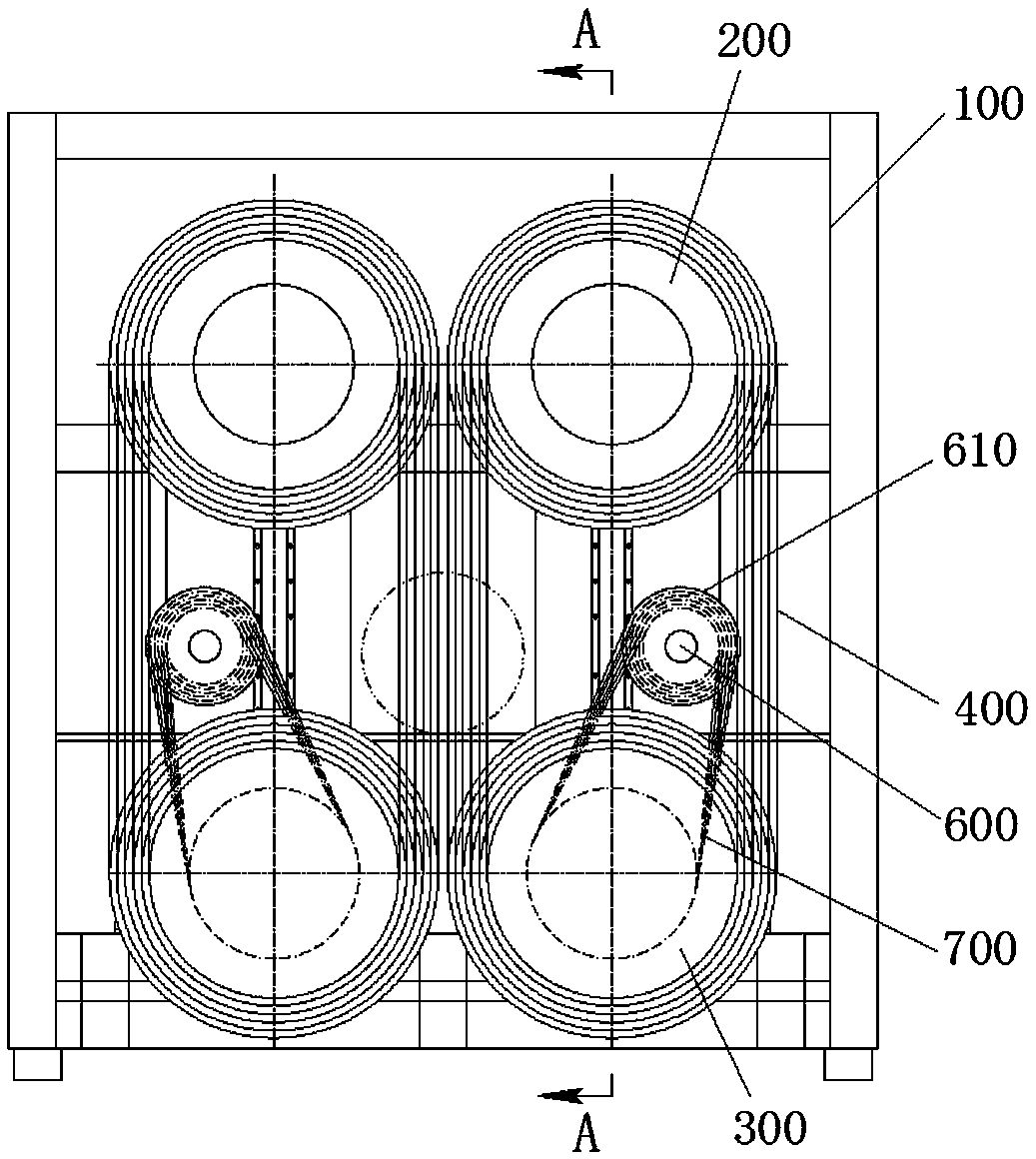

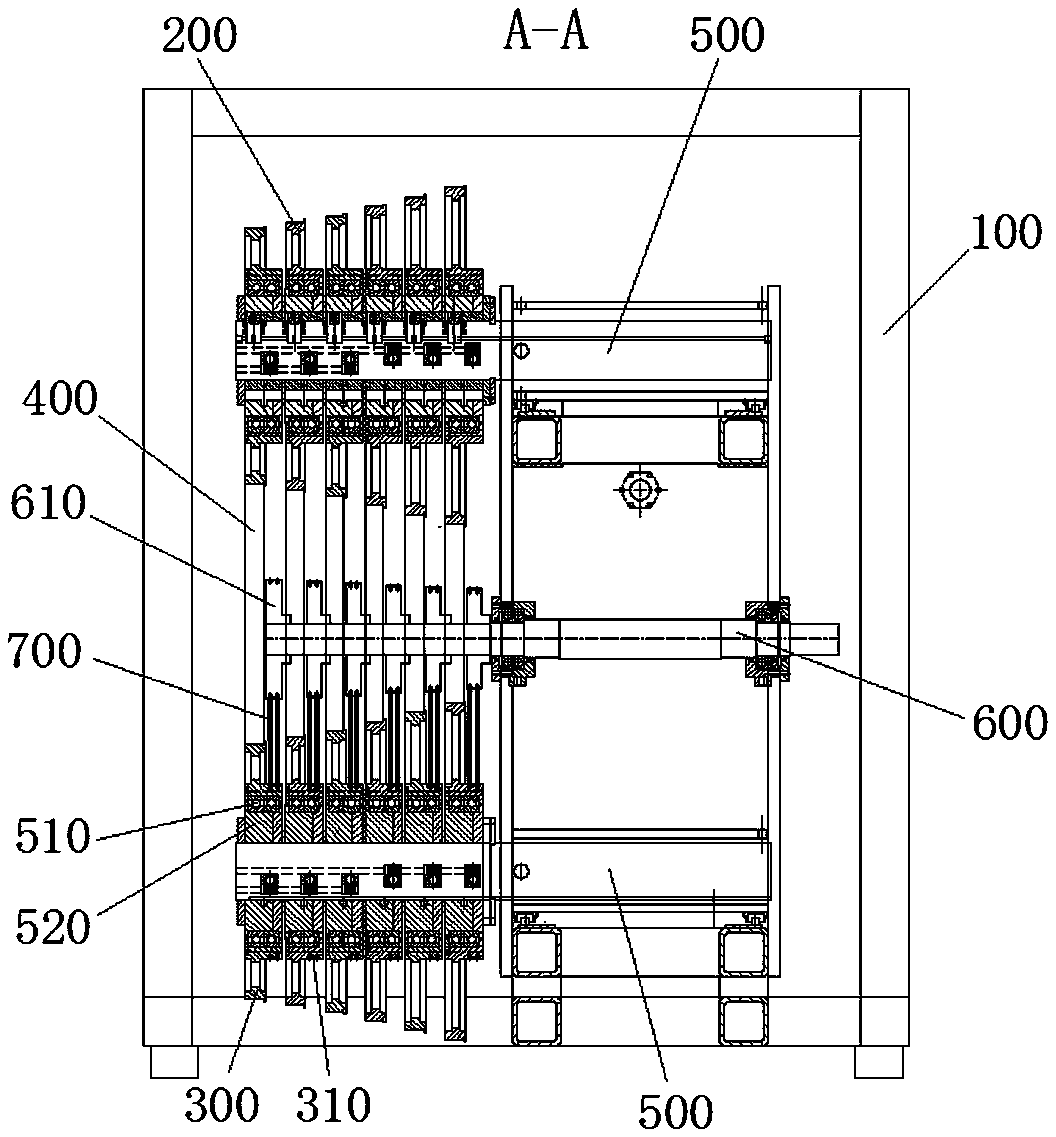

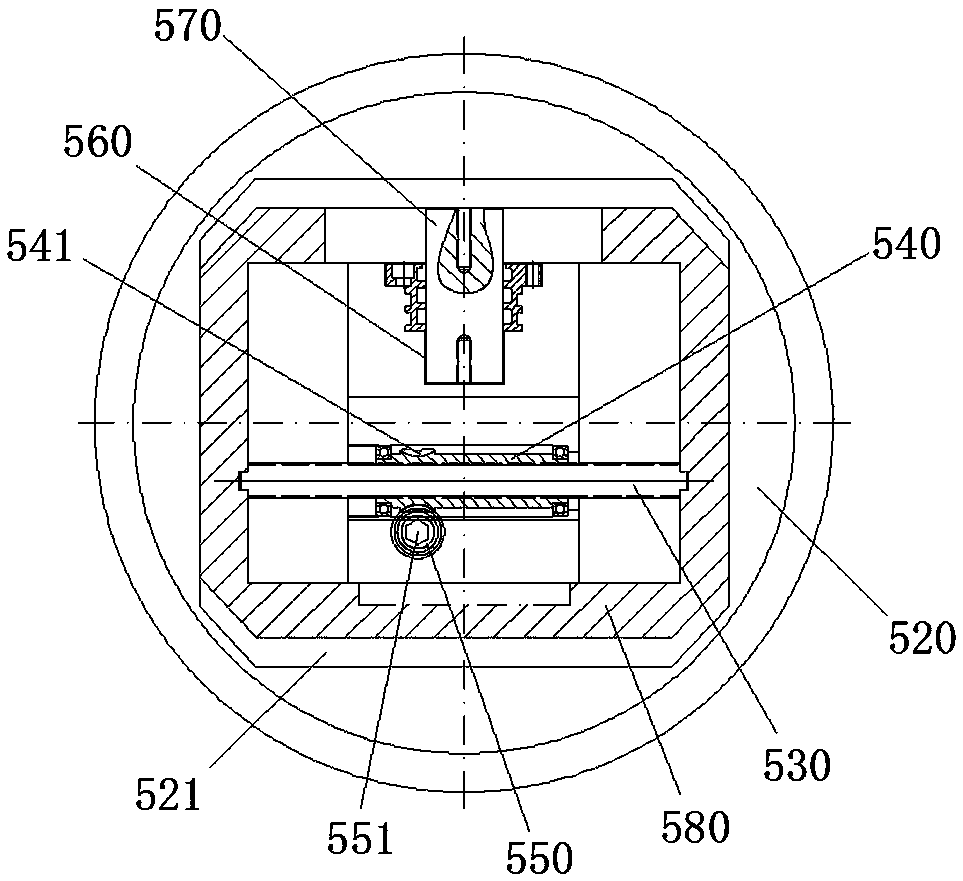

[0024] Embodiment one: if Figure 1~7 As shown, a multi-band saw with adjustable cutting thickness includes a frame 100, and at least one group of band saws is arranged on the frame 100, and each group of band saws includes a plurality of upper pulleys with increasing diameters coaxially arranged 200 and the lower pulley 300 and a plurality of band saw blades 400 forming a multi-circle ring structure, the upper and lower parts of the frame 100 are respectively provided with a square shaft 500 for installing the upper pulley and the lower pulley, each upper pulley 200 and the lower pulley 300 are rotatably matched with a connection plate 520 through a bearing 510, and the connection plate is set on the square shaft 500 and can move left and right relative to the square shaft 500. Position adjustment mechanism; each connection plate is equipped with an independent adjustment mechanism on the square shaft, through which the left and right positions of the connection plate can be ...

Embodiment 2

[0035] Embodiment 2: Since the multi-band saw can use the lower pulley as the driving pulley, or the upper pulley as the driving pulley, the difference between this embodiment and Embodiment 1 is that the upper pulley is used as the driving pulley. The drive shaft is fitted with a plurality of upper pulleys corresponding to one by one and pulleys with decreasing diameters, and the pulleys are connected to the corresponding upper pulleys through transmission belts; the upper pulleys are provided with belts for covering the transmission belts. The installation part is provided with a belt groove on the belt installation part, and the diameters of the belt installation parts of all the upper pulleys are the same.

[0036] A working method for multi-band saws with adjustable cutting thickness as described above. Insert the hexagonal wrench into the corresponding worm through the through hole, and turn the worm through the action of the screw sleeve and the screw so that the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com