Condensing type white smoke removing system and method for flue gas slurry

A flue gas and slurry technology, applied in separation methods, chemical instruments and methods, water shower coolers, etc., can solve problems such as high cost, unremoved pollutants, and environmental hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

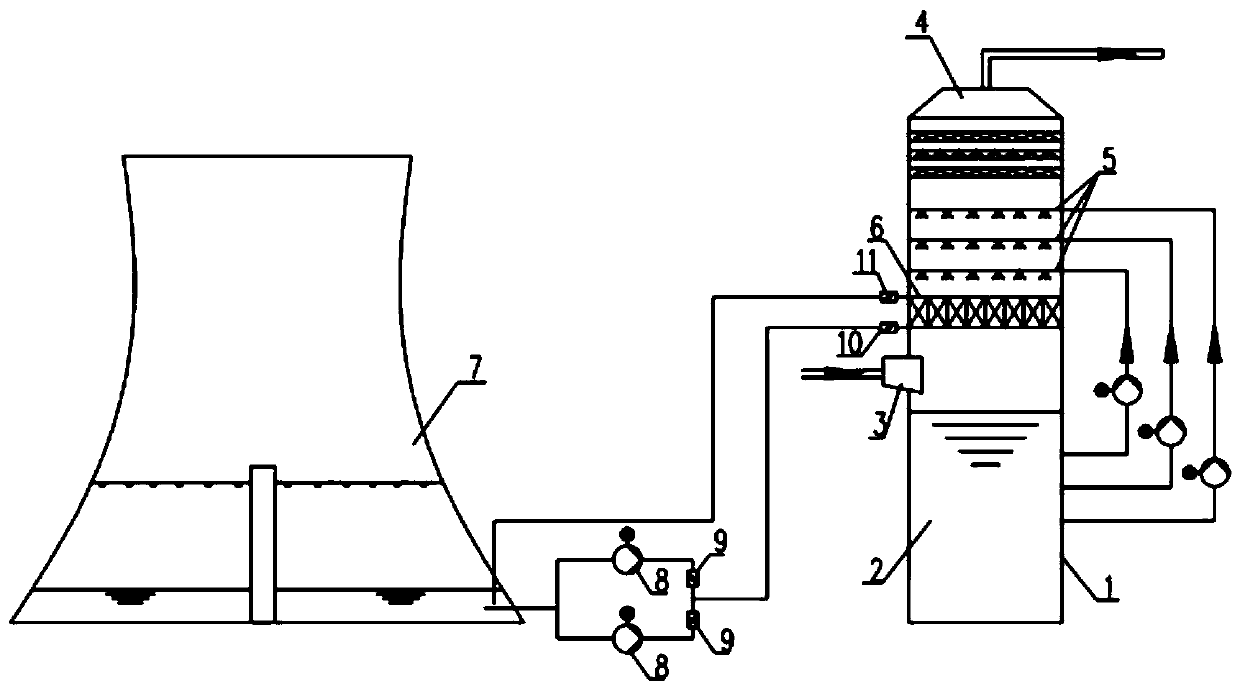

[0059] Such as figure 1 As shown, a flue gas slurry condensation type whitening system includes a desulfurization tower 1, a heat exchange layer and a cooling water tower 7, and the desulfurization tower 1 is sequentially provided with a slurry pool 2, a flue gas inlet 3, and a heat exchange layer from bottom to top 6. Spray layer 5, demister, flue gas outlet 4, slurry tank 2 is connected to the spray layer 5 through a pipeline, and the pipeline is provided with a first water pump; the demister can carry the water droplets carried in the flue gas remove.

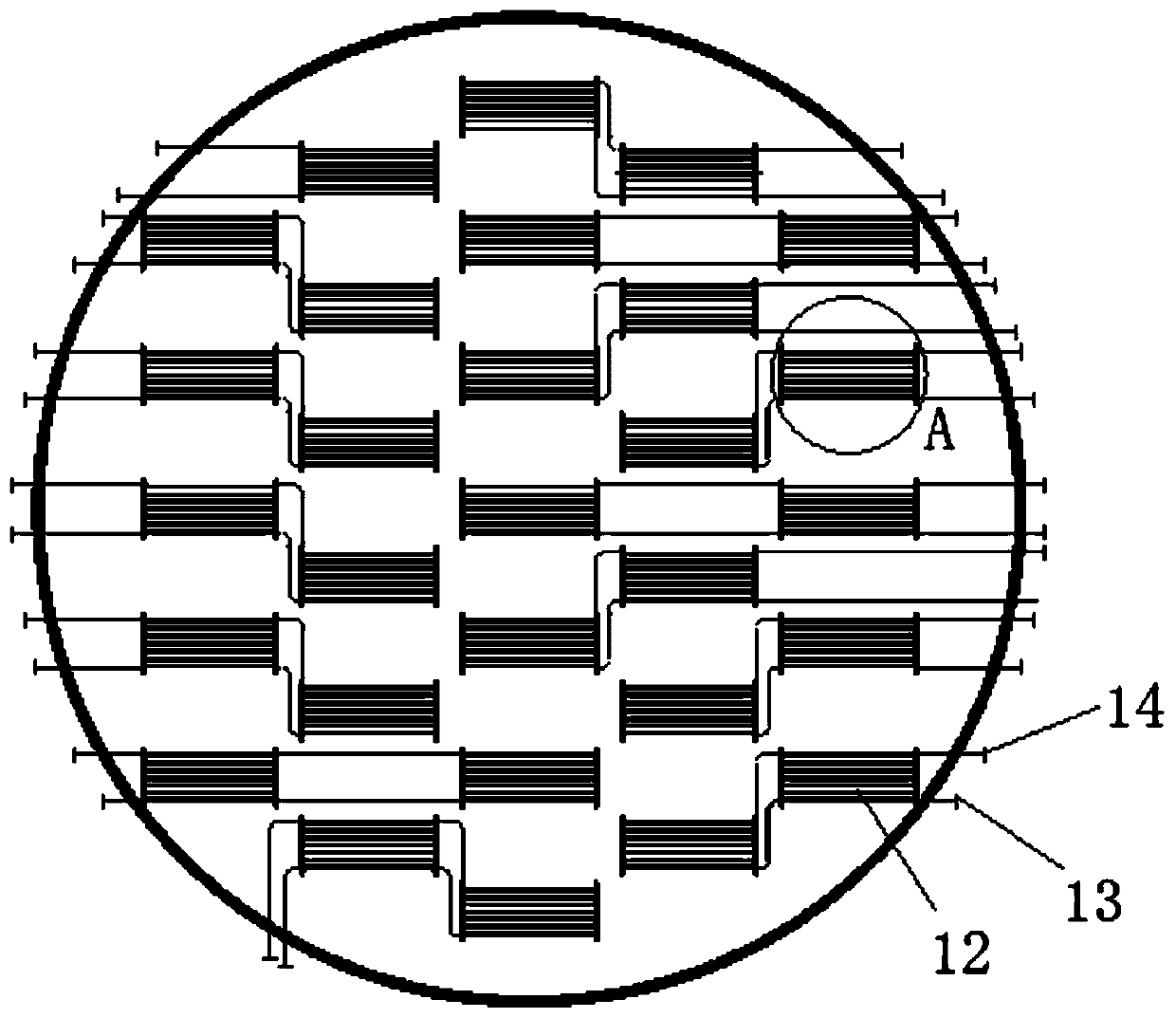

[0060] Such as figure 2 As shown, the heat exchange layer 6 includes 29 heat exchangers 15, and the 29 heat exchangers 15 are evenly distributed on the cross section of the desulfurization tower 1, and are arranged in 5 rows, from left to right, each row of heat exchangers The quantity is 5, 6, 7, 6, 5, suitable for the circular section of the desulfurization tower 1.

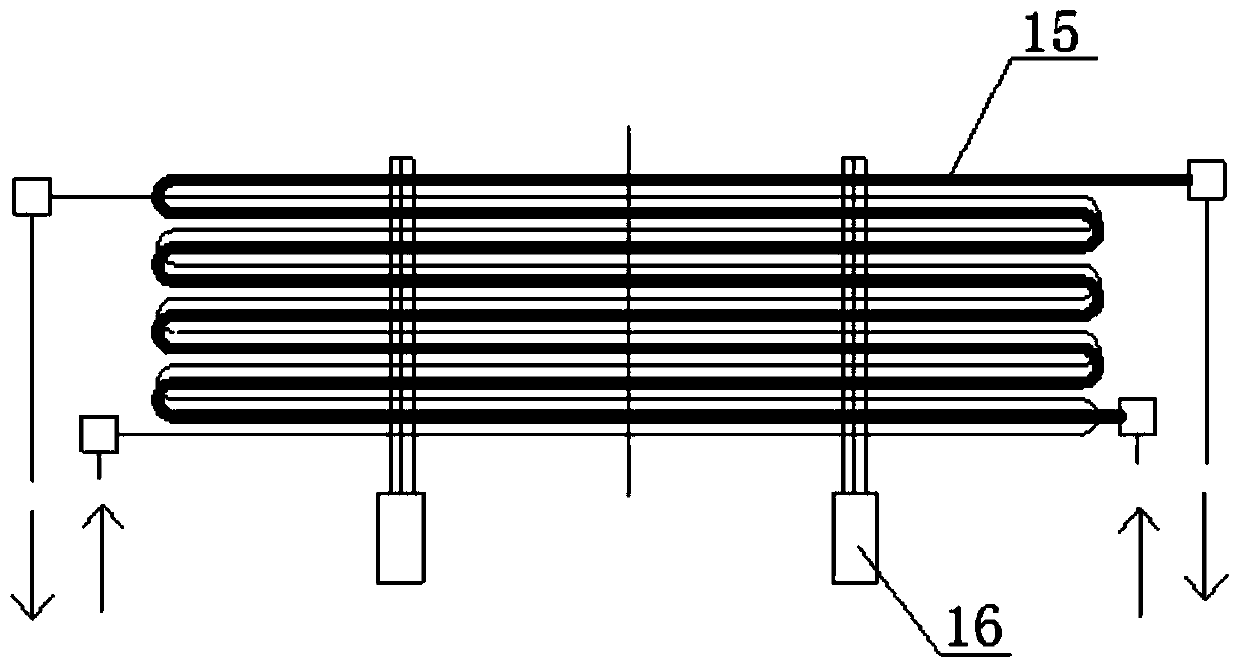

[0061] Such as image 3 , Figure 4 and Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com