Split type mold for hollow sphere precise manufacturing

A split, hollow ball technology, applied in the field of injection molding, can solve problems such as increased sales costs and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

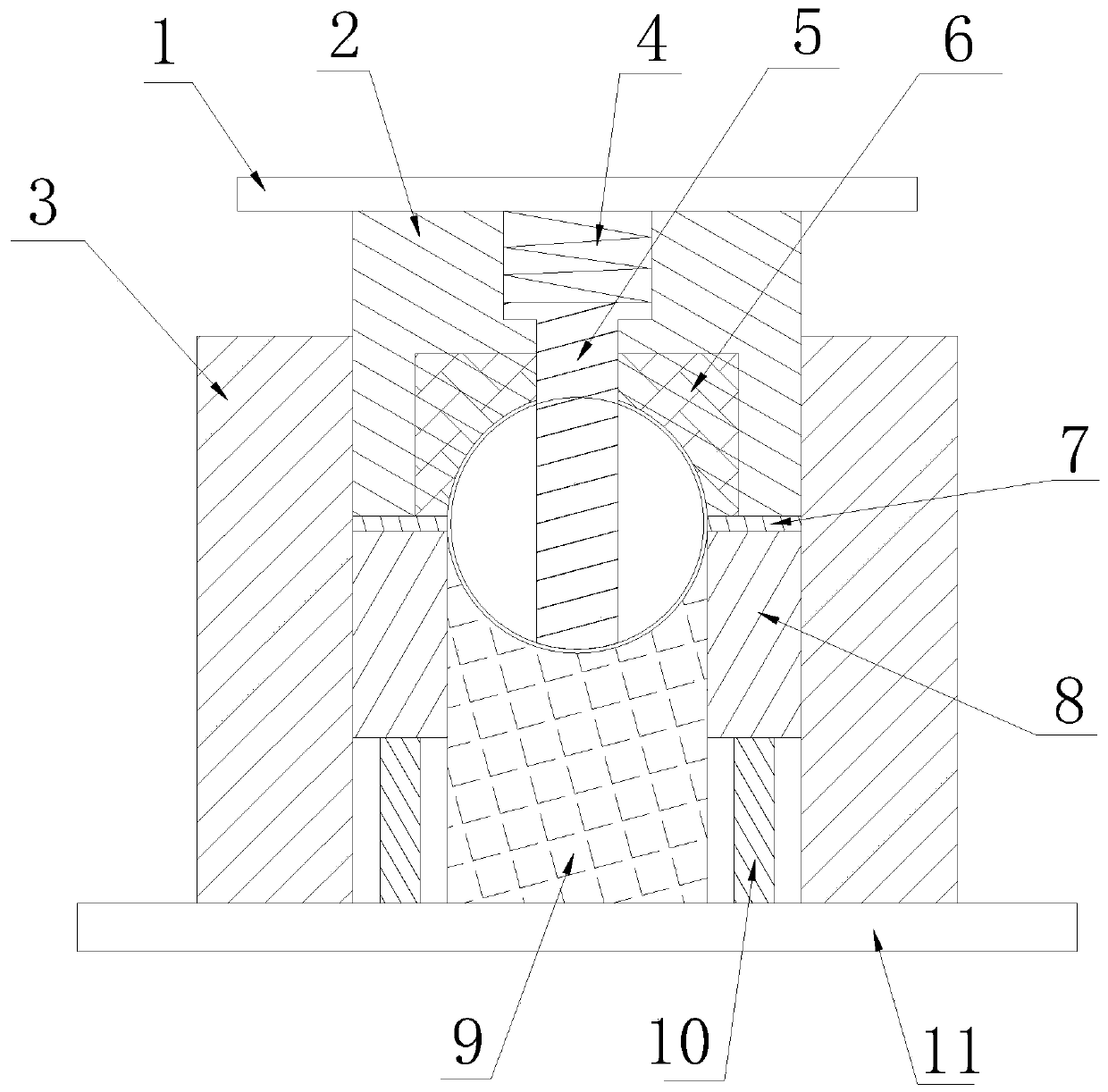

Embodiment 1

[0018] To make a hollow ball with a diameter of 50 cm, first, the upper mold 2, the compression spring 4, the upper mold inner ejector rod 5 and the upper mold inner phase block 6 are retracted to the upper point, and secondly, the lower cylinder pushes the ejector rod 10 to the guide ring 8 and The telescopic piece 7 reaches the mouth edge taper of the outer guide mold 3, and then puts the semi-finished product into the lower mold 9, and then the upper mold 2 goes down to the position of 25 cm from the center of the ball, and then the upper mold 2 returns, and the ejector rod 10 is compressed. Under the action of the spring 4, the bottom surface of the ball is pressed to prevent the ball from sticking to the cavity of the upper mold 2. Next, the lower cylinder pushes the ejector rod 10 again so that the guide ring 8 and the telescopic piece 7 rise to the taper of the mouth of the outer guide mold 3. Return to the original state, because the telescopic sheet 7 is quartered and ...

Embodiment 2

[0020] To make a hollow ball with a diameter of 80cm, firstly, the upper mold 2, the compression spring 4, the upper mold inner ejector rod 5 and the upper mold inner phase block 6 are retracted to the upper point, and secondly, the lower cylinder pushes the ejector rod 10 to the guide ring 8 and The telescopic piece 7 reaches the mouth edge taper of the outer guide mold 3, then puts the semi-finished product into the lower mold 9, and then the upper mold 2 goes down to the position of 40 cm from the center of the ball, then the upper mold 2 returns, and the ejector rod 10 is compressed Under the action of the spring 4, the bottom surface of the ball is pressed to prevent the ball from sticking to the cavity of the upper mold 2. Next, the lower cylinder pushes the ejector rod 10 again so that the guide ring 8 and the telescopic piece 7 rise to the taper of the mouth of the outer guide mold 3. Return to the original state, because the telescopic sheet 7 is quartered and evenly s...

Embodiment 3

[0022] To make a hollow ball with a diameter of 90 cm, first, the upper mold 2, the compression spring 4, the upper mold inner ejector rod 5 and the upper mold inner phase block 6 are retracted to the upper point, and secondly, the lower cylinder pushes the ejector rod 10 to the guide ring 8 and The telescopic piece 7 reaches the mouth edge taper of the outer guide mold 3, then puts the semi-finished product into the lower mold 9, and then the upper mold 2 goes down to the position of 45 cm from the center of the ball, then the upper mold 2 returns, and the ejector rod 10 is compressed Under the action of the spring 4, the bottom surface of the ball is pressed to prevent the ball from sticking to the cavity of the upper mold 2. Next, the lower cylinder pushes the ejector rod 10 again so that the guide ring 8 and the telescopic piece 7 rise to the taper of the mouth of the outer guide mold 3. Return to the original state, because the telescopic sheet 7 is quartered and evenly sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com