Vehicle Pneumatic Tires

A technology for pneumatic tires, vehicles, applied in vehicle parts, tire parts, tire treads/tread patterns, etc., to solve problems such as dry lane braking and adverse effects on operating characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

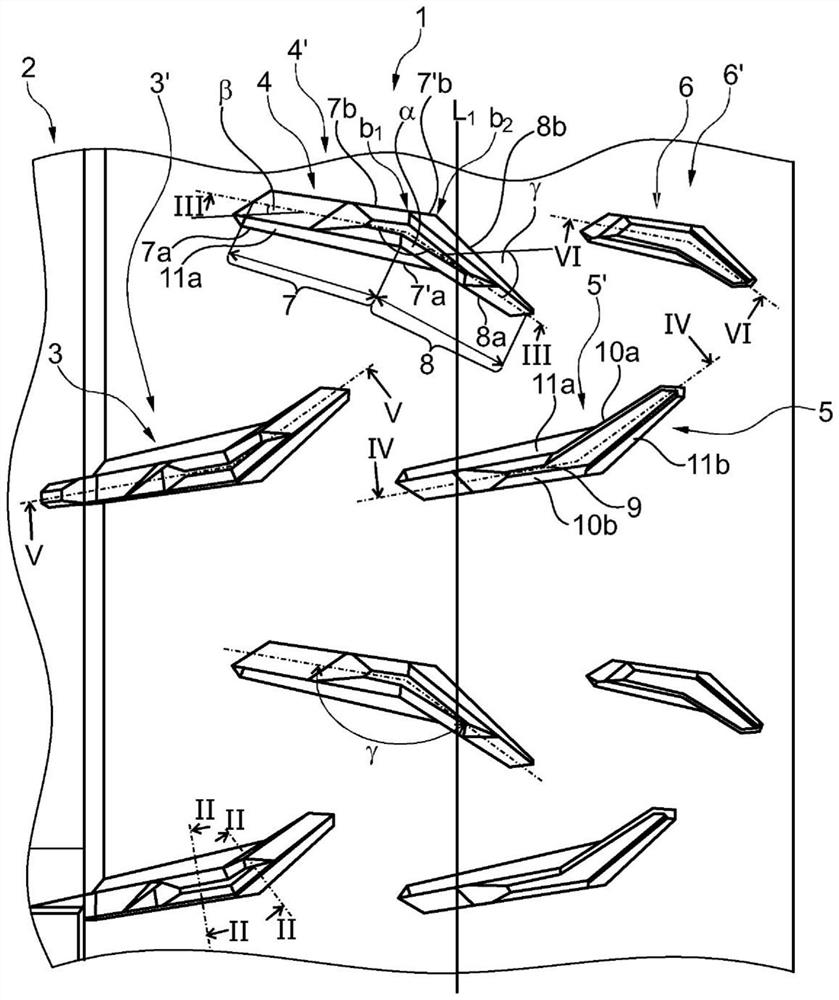

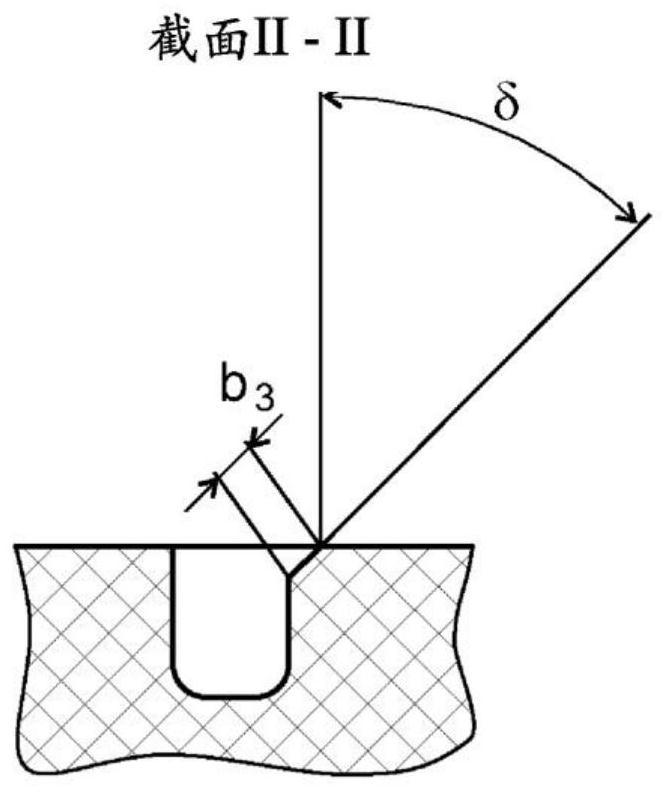

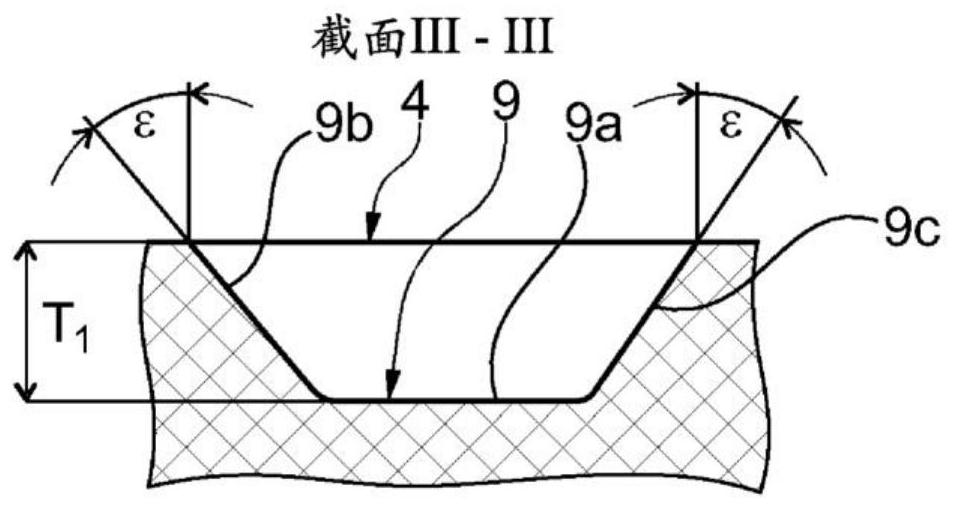

[0024] The pneumatic tire for vehicles embodied according to the invention is in particular a tire of radial construction for passenger cars, vans or light trucks. A "tread band" in the sense of the present invention encircles the tread in the circumferential direction and is equipped with grooves which either run completely within the tread band or at least with one of their ends are within the tread band termination.

[0025] exist figure 1 shows a circumferential section of a tread band 1 on the shoulder side of a tread of a pneumatic tire for a vehicle, which is bounded on the inside of the tread by a circumferential groove 2 . A vehicle pneumatic tire whose tread has the tread band 1 only in one of its shoulders is preferably mounted on the vehicle such that the tread band 1 runs along the tire assigned to the inside of the vehicle in the installed state of the vehicle pneumatic tire. Tread shoulder positioning. Alternatively, the tread of a vehicle pneumatic tire may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com