Angle-adjustable pipeline connecting structure, installing method and long-line pipeline

A connection structure and angle adjustment technology, applied in the direction of adjustable connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve problems such as pipe angle steering, avoid liquid leakage and save time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

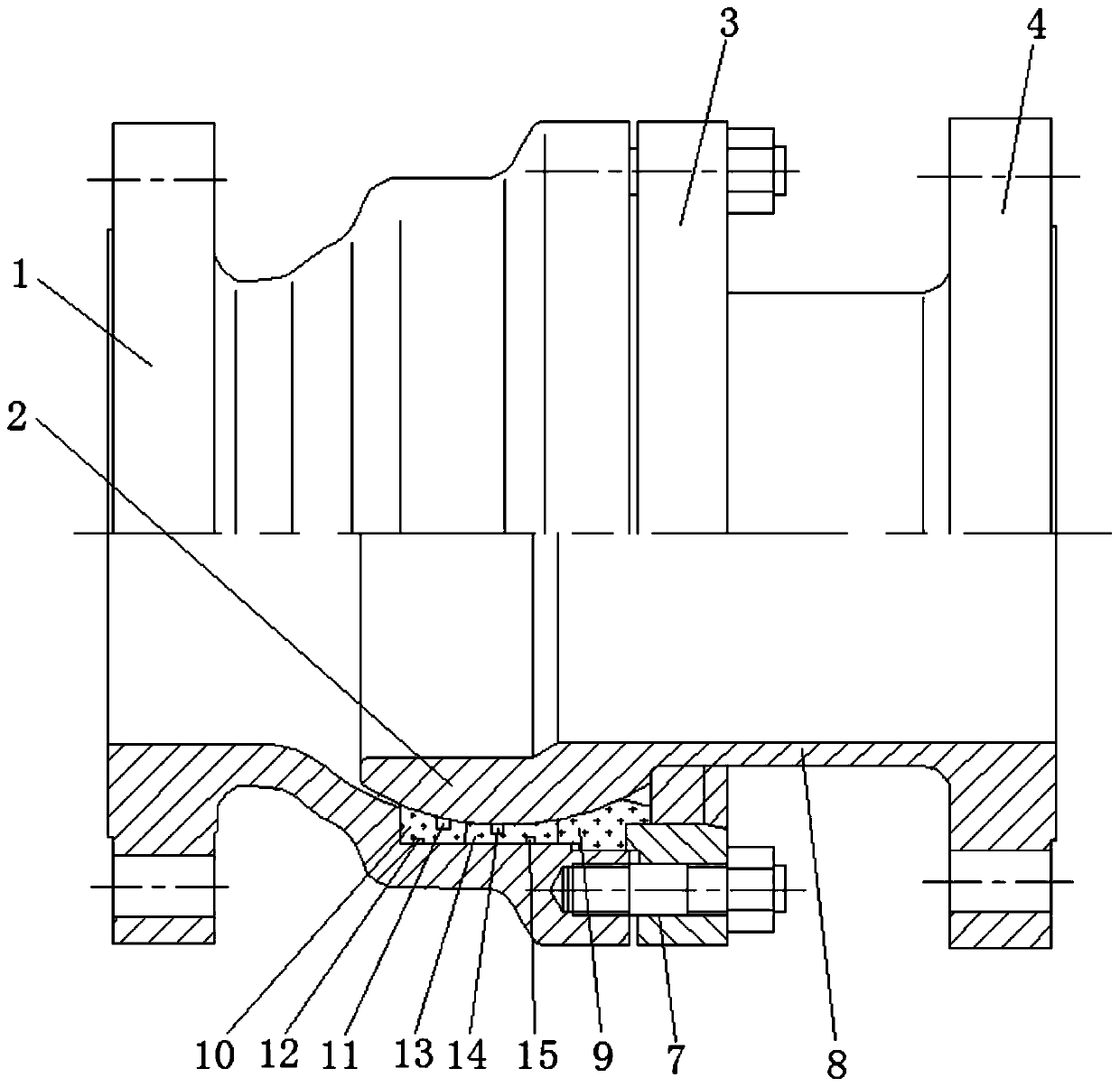

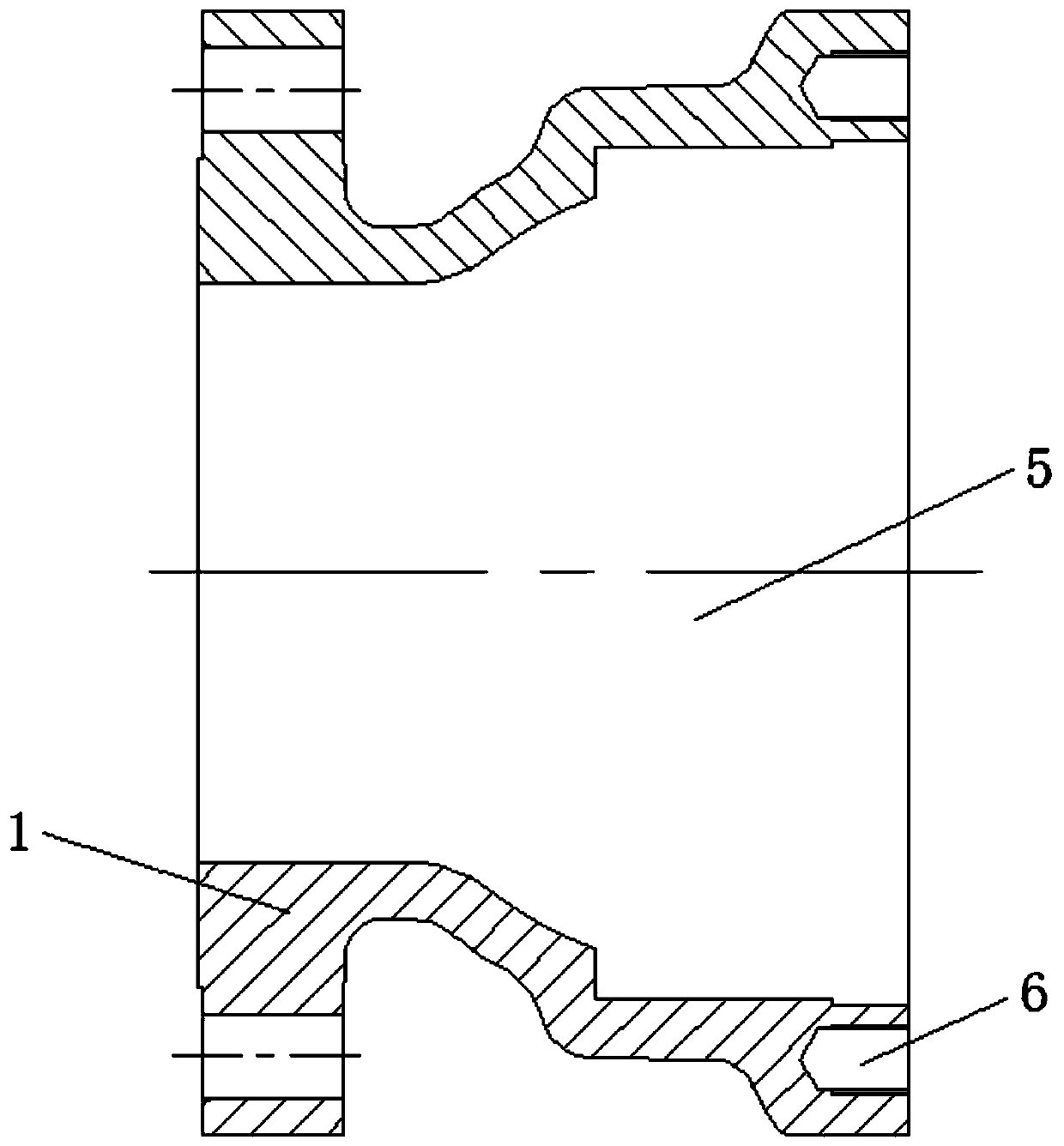

[0040] Such as Figure 1~2 As shown, an angle-adjustable pipeline connection structure includes a valve body 1, a valve ball 2, a first flange 3 and a second flange 4; one end of the valve body 1 is provided with a connecting cavity 5, the The end is provided with an interface with a small inner side and a large outer side; the valve body 1 is also provided with a first connecting portion 6; the first flange 3 is provided with a second connecting portion 7; the second connecting portion 7 is connected to the The first connecting part 6 is connected; the valve ball 2 is located inside the connecting cavity 5; the second flange 4 passes through the first flange 3 through the water supply pipe 8 to connect the interface with the valve ball 2 .

[0041] The present invention realizes the rotation of the water supply pipeline 8 through the setting of the valve ball 2, and the interface is set to be small on the inside and large on the outside, so that when the pipeline rotates, it ...

Embodiment 2

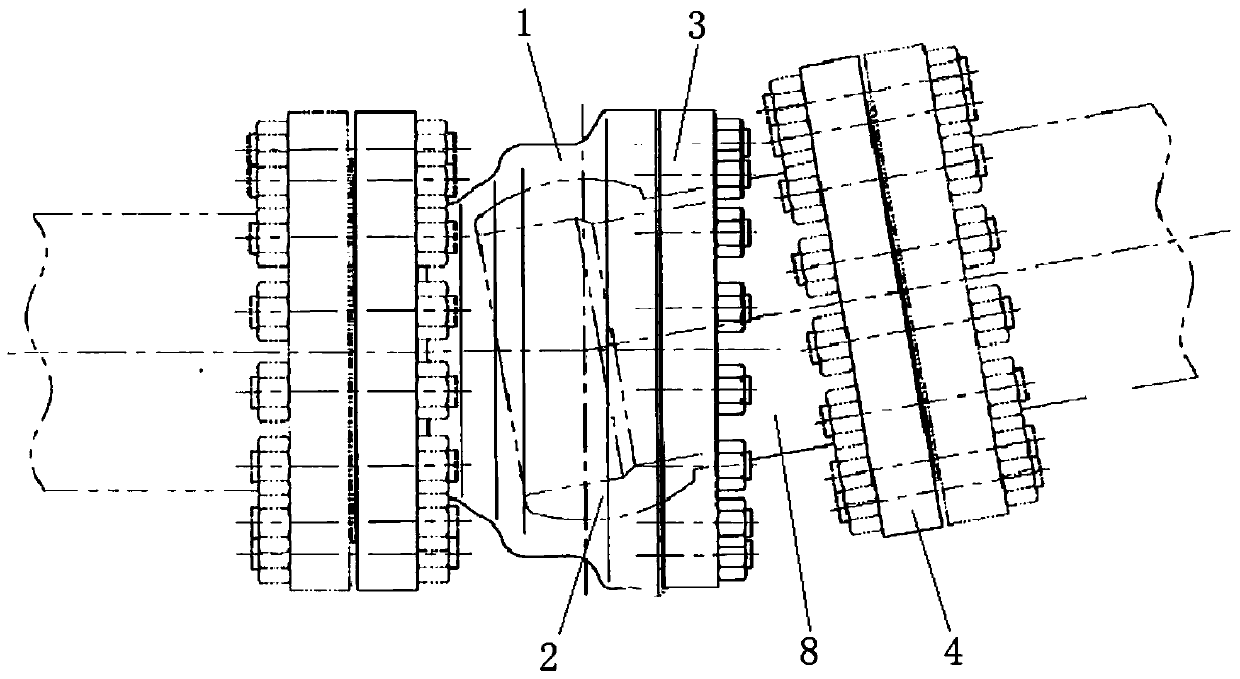

[0048] Such as image 3 As shown, a long-line pipeline has an angle-adjustable pipeline connection structure.

[0049] By using the above-mentioned angle-adjustable pipeline connection structure to connect long-line pipelines, the problems of misalignment correction and steering during the pipeline connection process can be greatly solved, making pipeline connection more flexible and providing more convenience for pipeline construction; On this basis, the long-line pipeline also has good sealing and wear resistance, and can work in high-pressure medium conditions.

[0050] In this embodiment, the size of the interface connecting the inner cavity 5 can make the valve body 1 rotate 0-10° in the connecting inner cavity 5, so as to achieve a maximum selection angle of 20°. In this embodiment, the specific connection structure The installation steps are as follows:

[0051] (a) Install the sealing ring at the corresponding positions of the retaining ring 10 and the packing ring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com