Solenoid selection valve

A technology for selecting valves and solenoid valves, applied in the direction of sliding valves, valve details, multi-way valves, etc., to achieve the effects of easy operation, improving liquid applicability, and avoiding liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

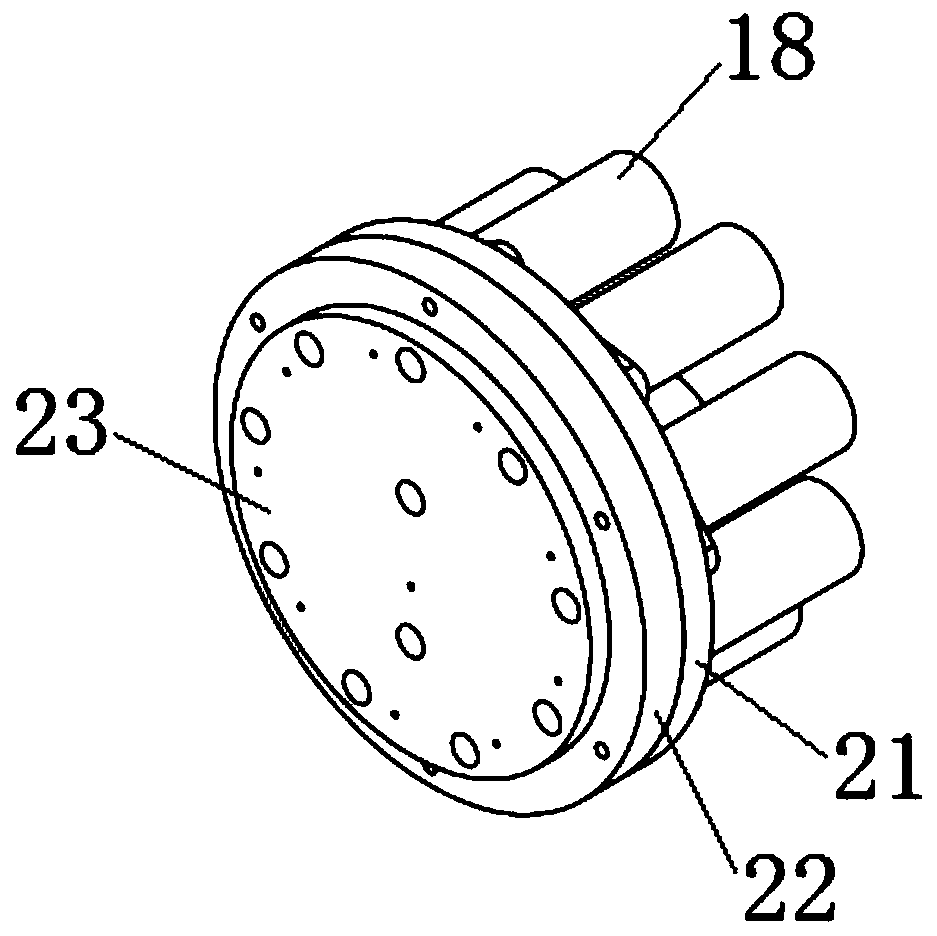

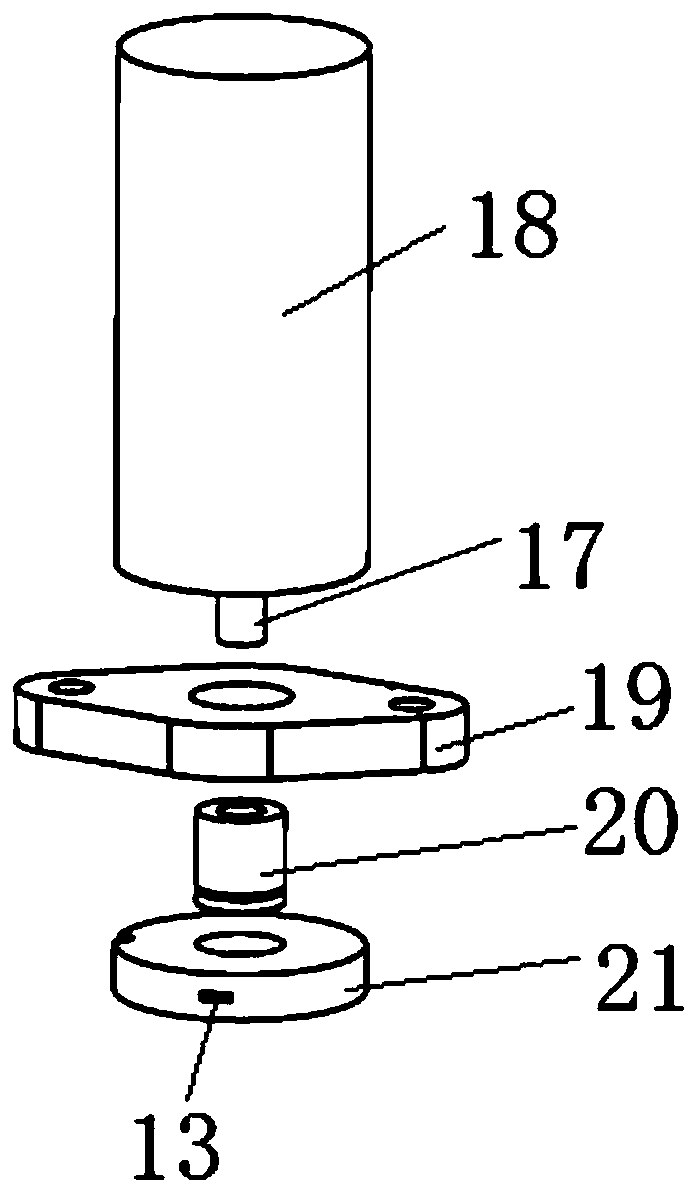

[0036] Such as figure 1 As shown, the electromagnetic selector valve of the present invention includes a valve body, and a plurality of one-to-one corresponding lifting electromagnetic valves 18 , electromagnetic valve fixing pieces, valve cores and valve core seats 21 . The valve body includes a valve body one 23 and a valve body two 22 bonded together.

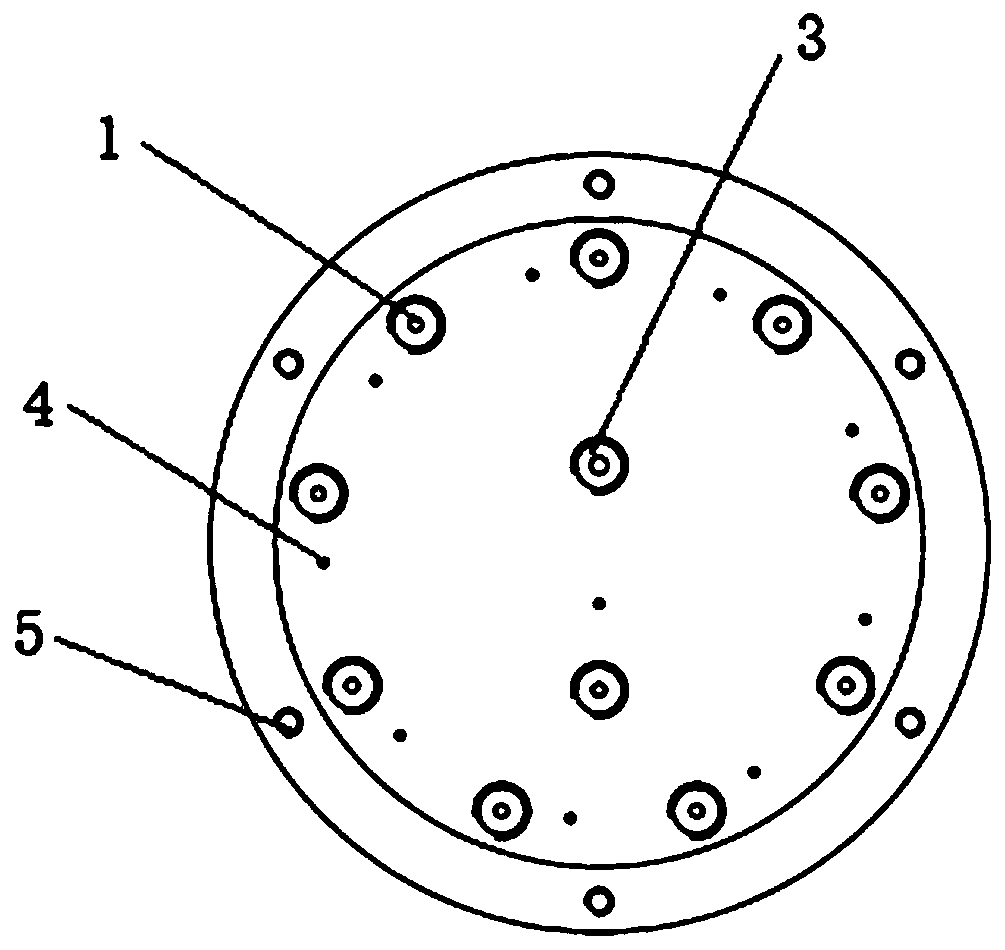

[0037] Take the ten-way valve as an example, such as image 3 As shown, the valve body 1 has ten liquid inlet holes 1, nine of which are equally distributed in a ring around the installation surface of the valve body 1, and the other is at the lower position in the middle of the valve surface. Correspondingly, the bonding surface of the valve body 1 is engraved with nine long and one short liquid circulation grooves 2 (such as Figure 4 As shown), the ten grooves 2 intersect at one point, which is set as the liquid outlet and communicates with the liquid outlet hole 3 provided on the mounting surface. A number of ventilat...

Embodiment 2

[0046] This embodiment is an example of a single-way solenoid valve, and the structural difference from the multi-way electromagnetic selector valve in Embodiment 1 is that the number of the valve core 410, the lifting solenoid valve 510, the solenoid valve fixing piece 511, and the valve core seat 310 are all one. The liquid inlet hole of valve body 1 is connected with the liquid inlet port of valve body 2, and the quantity is one; the liquid outlet hole of valve body 1 is connected with the liquid outlet of valve body 2, and the number is one; The bonding surface is no longer provided with grooves; other structures are consistent with those in Example 1, such as Figure 11 , Figure 12 shown.

[0047] Such as Figure 12 As shown, the specific working principle of the single-way solenoid valve is: the liquid enters the liquid circulation inlet hole 311 of the valve core seat from the valve body liquid inlet 111, when the solenoid valve lifts the valve core up, the passage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com