Municipal drainage pipeline with solid-liquid separation function

A municipal drainage and solid-liquid separation technology, which is applied in sewer systems, waterway systems, water supply devices, etc., can solve the problems of difficult detection of clogged locations, clogged pipes, and inconvenient maintenance, so as to reduce the probability of clogged filter holes and facilitate centralized cleaning , improve the effect of buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

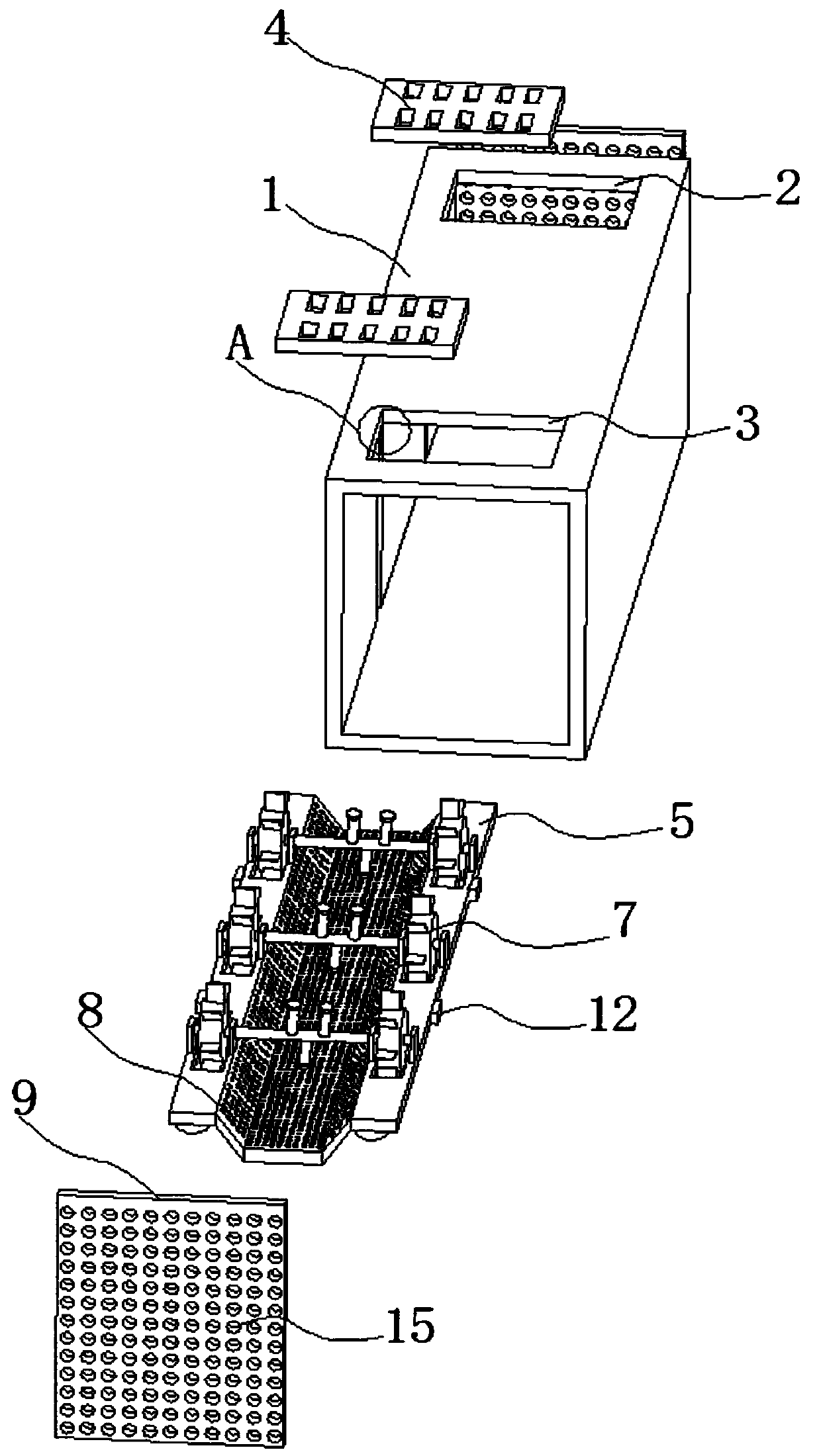

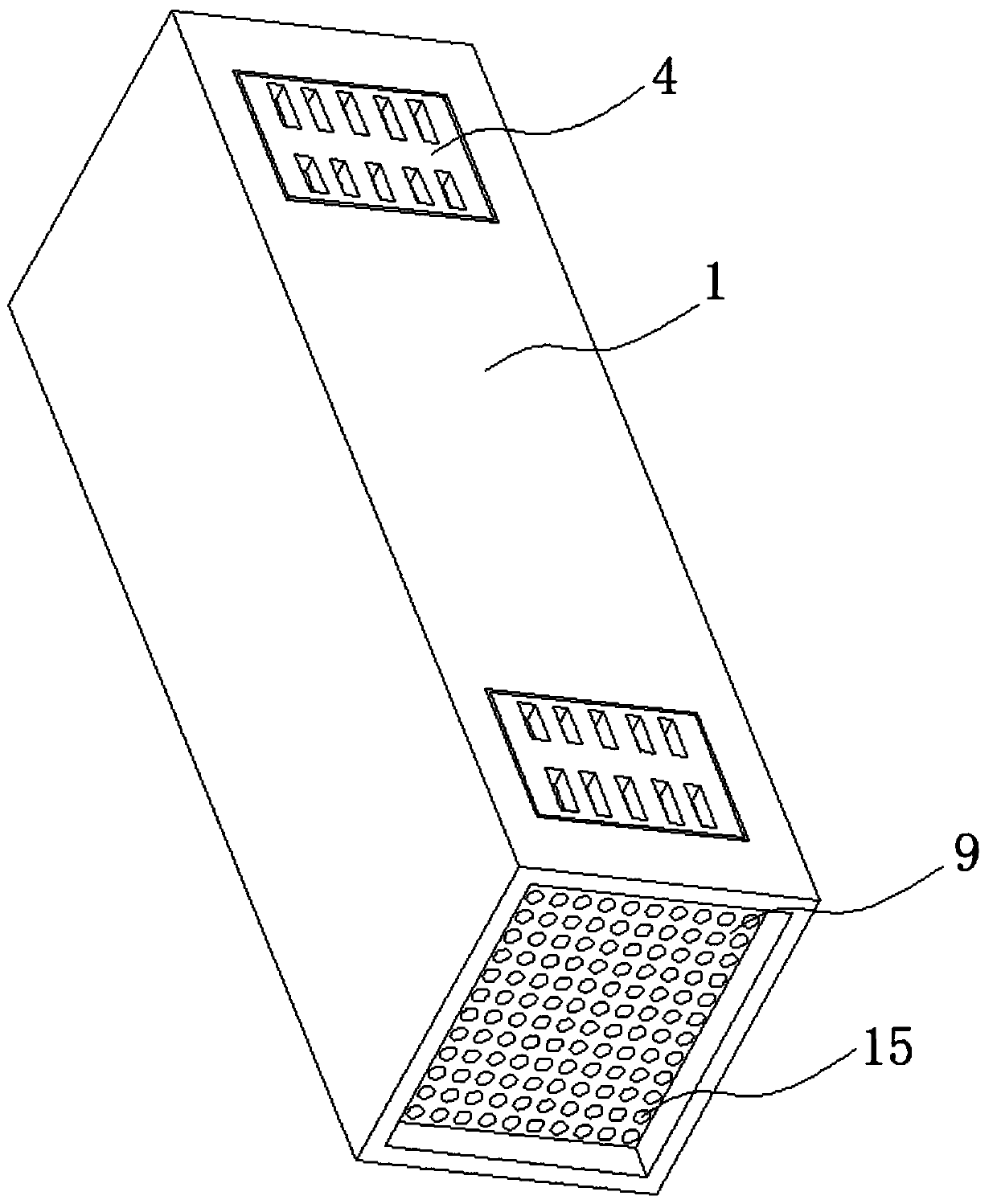

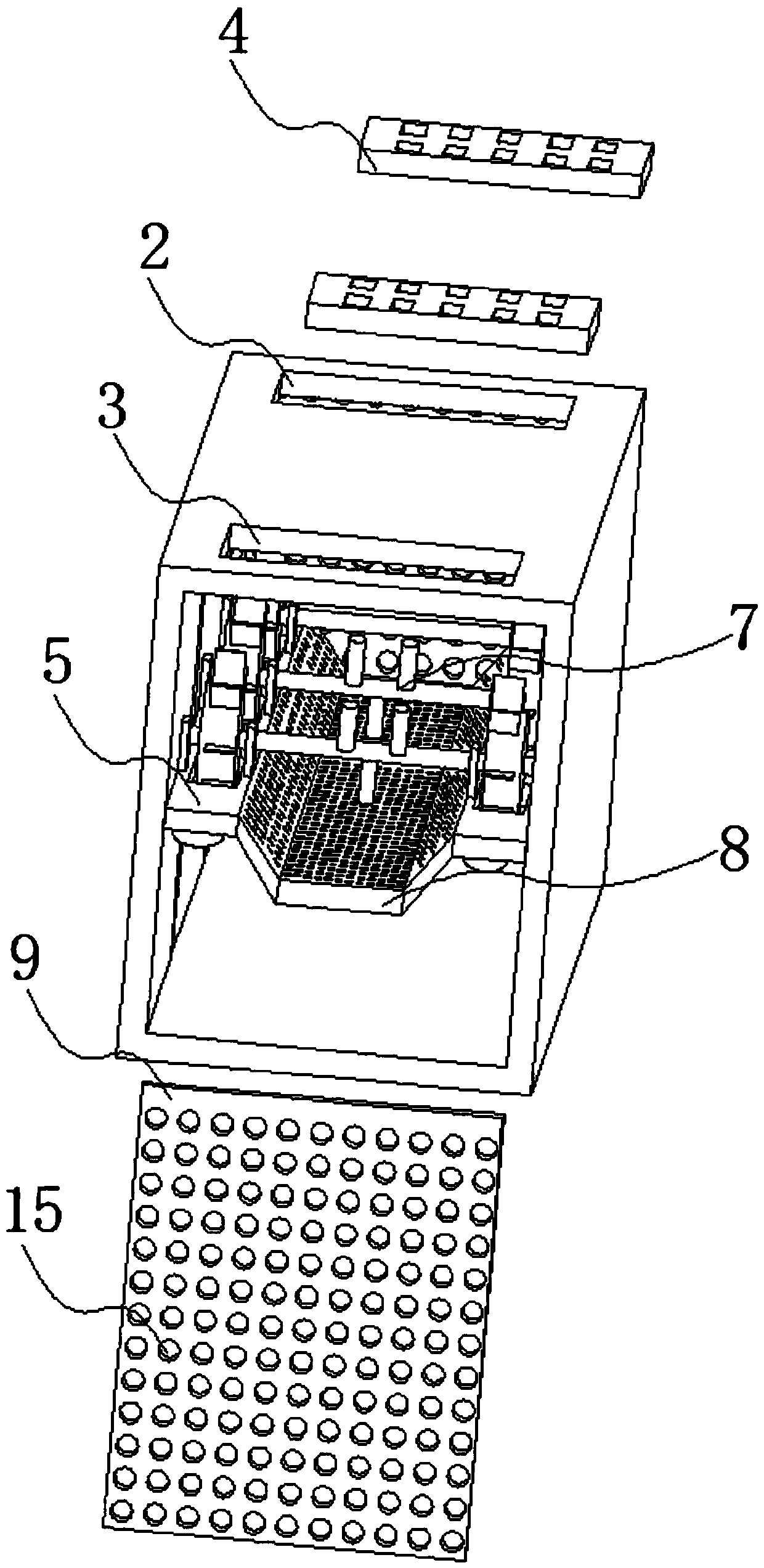

[0032] refer to Figure 1-3 , a municipal drainage pipeline with solid-liquid separation function, comprising a pipeline main body 1, the pipeline main body 1 is a square structure, the top of the pipeline main body 1 is dug with a water inlet opening 2 and an outlet 3, and the inside of the water inlet opening 2 and the outlet 3 Both are connected with drainage boards 4, and the inner side wall of the pipeline main body 1 is slidingly connected with two symmetrically distributed floating boards 5, and evenly distributed slots 6 are opened on the floating boards 5, and cleaning components 7 are connected to the floating boards 5 through brackets. A filter plate 8 is connected between the two floating plates 5, and two baffles 9 are also connected in the pipeline main body 1. The distributed seepage holes 15, the baffle plate 9 and the end of the floating plate 5 are offset; when there is water flow through the pipeline main body 1, the floating plate 5 drives the filter plate ...

Embodiment 2

[0034] refer to Figure 1-4 , a municipal drainage pipeline with solid-liquid separation function, which is basically the same as that of Embodiment 1, furthermore, the cleaning assembly 7 includes a micro water wheel 71, the micro water wheel 71 is connected to the floating plate 5 through a bracket, and the micro water wheel Wheel 71 is matched with slotting 6, is connected with rotating bar 72 between the adjacent miniature water wheels 71 on two floating plates 5, is connected with elastic force toggle bar 73 on the turn bar 72, and elastic force toggle bar 73 is positioned at filter. Directly above the plate 8; the water flowing in the pipeline main body 1 drives the micro water wheel 71 to rotate, the micro water wheel 71 bears the rotating rod 72 to rotate, the rotating rod 72 and the large elastic toggle rod 73 rotates, and then removes the solid impurities on the filter plate 8 Concentrated conveying is convenient for centralized cleaning of impurities.

Embodiment 3

[0036] refer to Figure 1-4 , a municipal drainage pipeline with solid-liquid separation function is basically the same as embodiment 1, furthermore, the bottom of the floating plate 5 is also connected with evenly distributed floats 10 to improve the buoyancy of the floating plate 5, and the filter plate 8 The height is greater than the height of the floating plate 5, and the top of the filter plate 8 is equal to the top of the floating plate 5, preventing impurities from accumulating too much and the floating plate 5 sinking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com