A control method of an intelligent laser coding system for plastic pipes

A laser coding, plastic pipe technology, applied in typewriters, printing, printing devices, etc., to reduce manual identification errors, ensure stability and reliability, and ensure complete effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following examples are used to illustrate the present invention and uses thereof, but are not intended to limit the protection scope of the present invention.

[0044] see Figure 1-7 ,

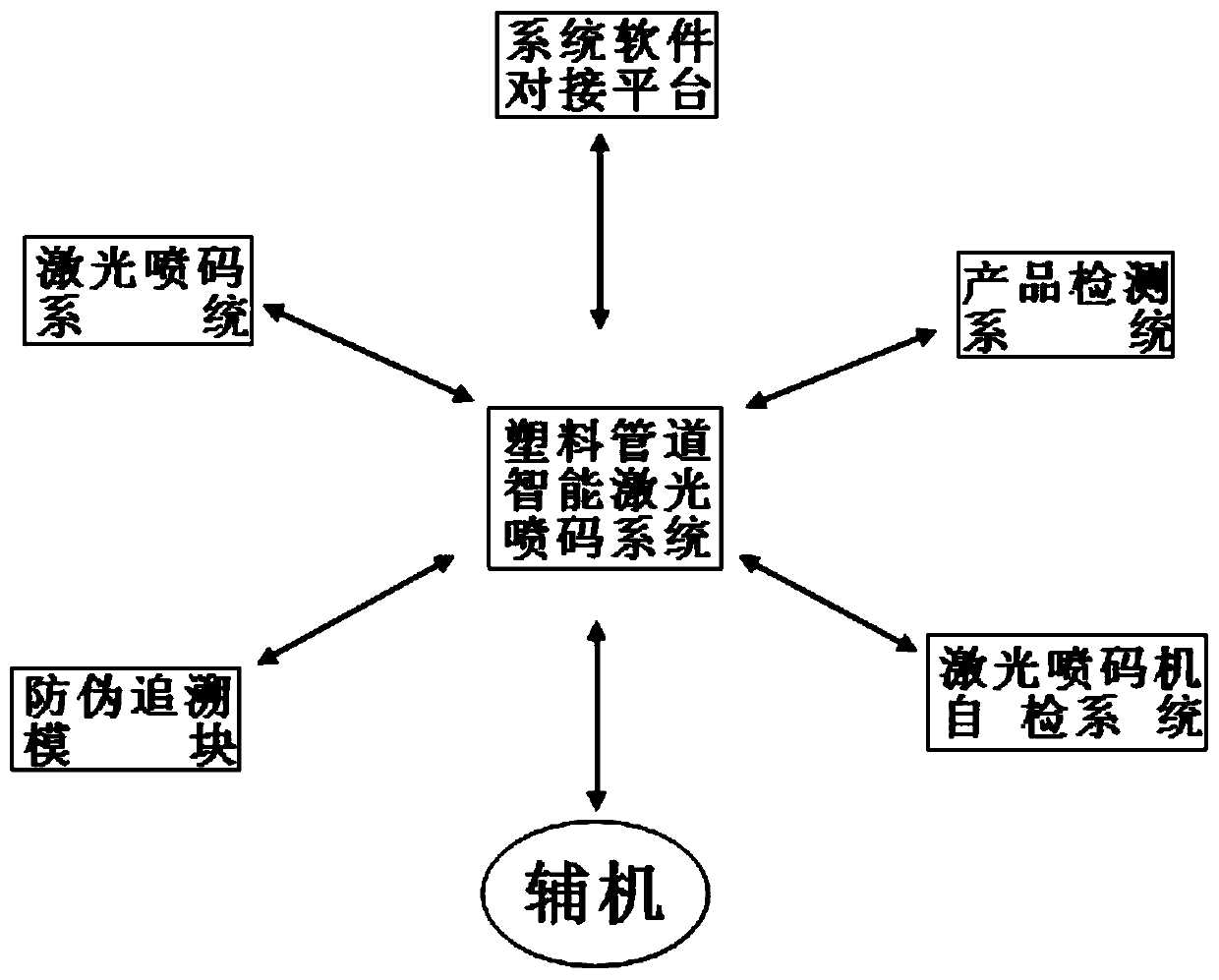

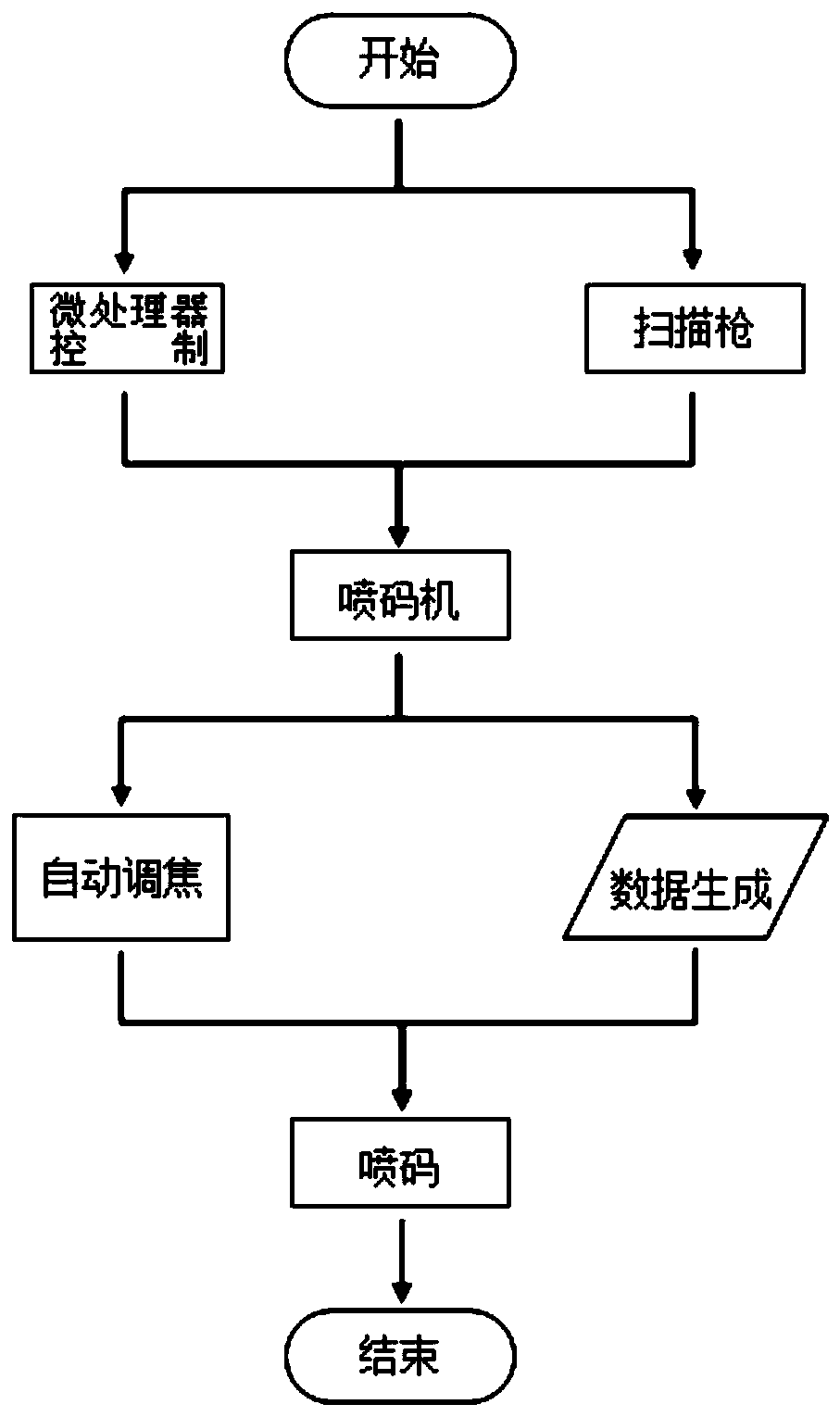

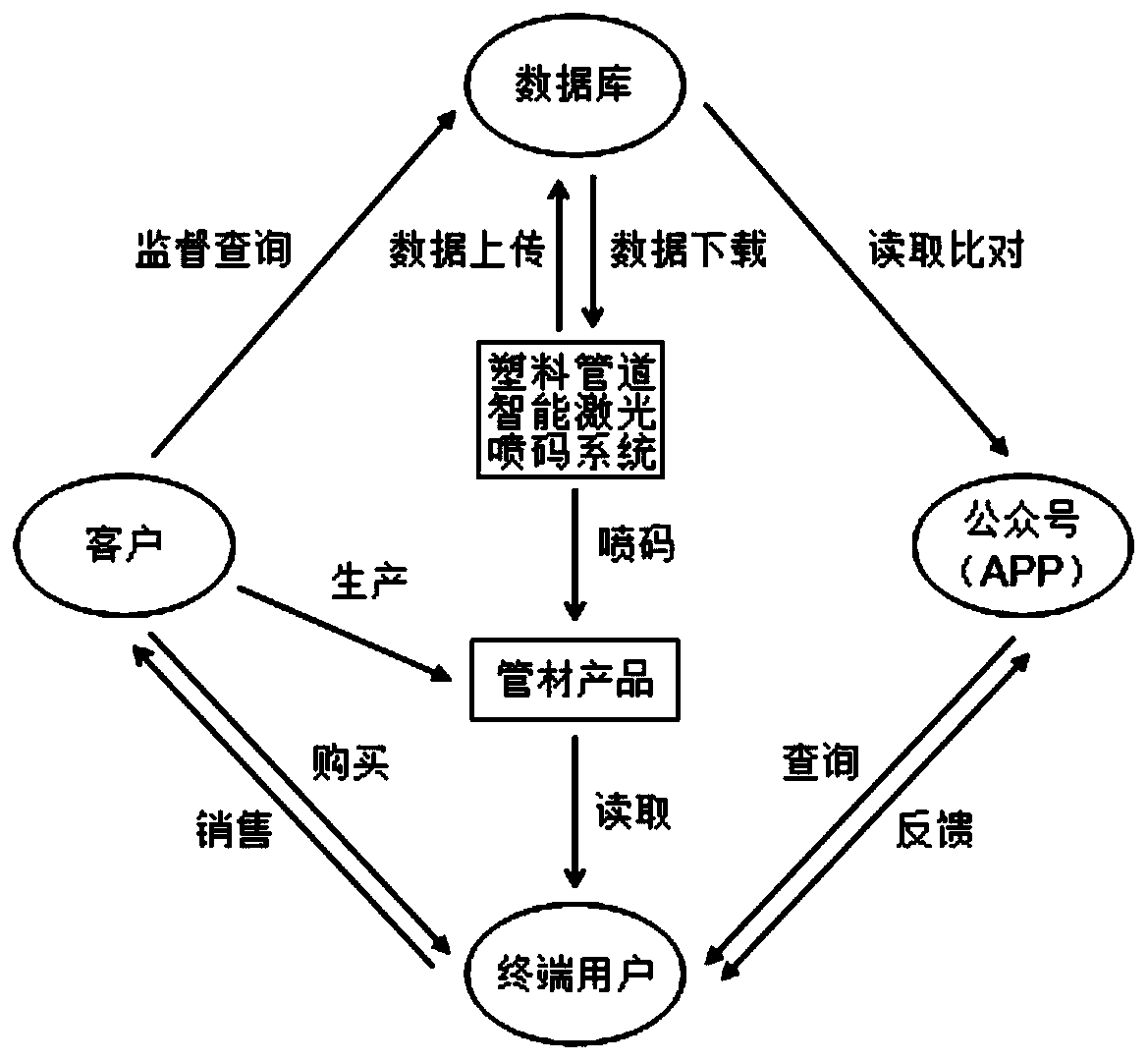

[0045] The present invention relates to a method for controlling a plastic pipeline intelligent laser coding system, including a microprocessor, a laser coding system, an ERP, an anti-counterfeiting traceability module, a system software docking platform, a product detection system, an auxiliary machine, and a laser coding machine. Check the system, there are the following steps:

[0046] 1) First realize the connection control with the laser inkjet coding system, ERP, anti-counterfeiting traceability module, system software docking platform, product inspection system, auxiliary machine and laser inkjet printer self-inspection system through the microprocessor;

[0047] 2) The communication control between the microprocessor and ERP is by realizing the ERP order of the inkjet manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com