Combined noodles containing wheat aleurone layers and preparation method thereof

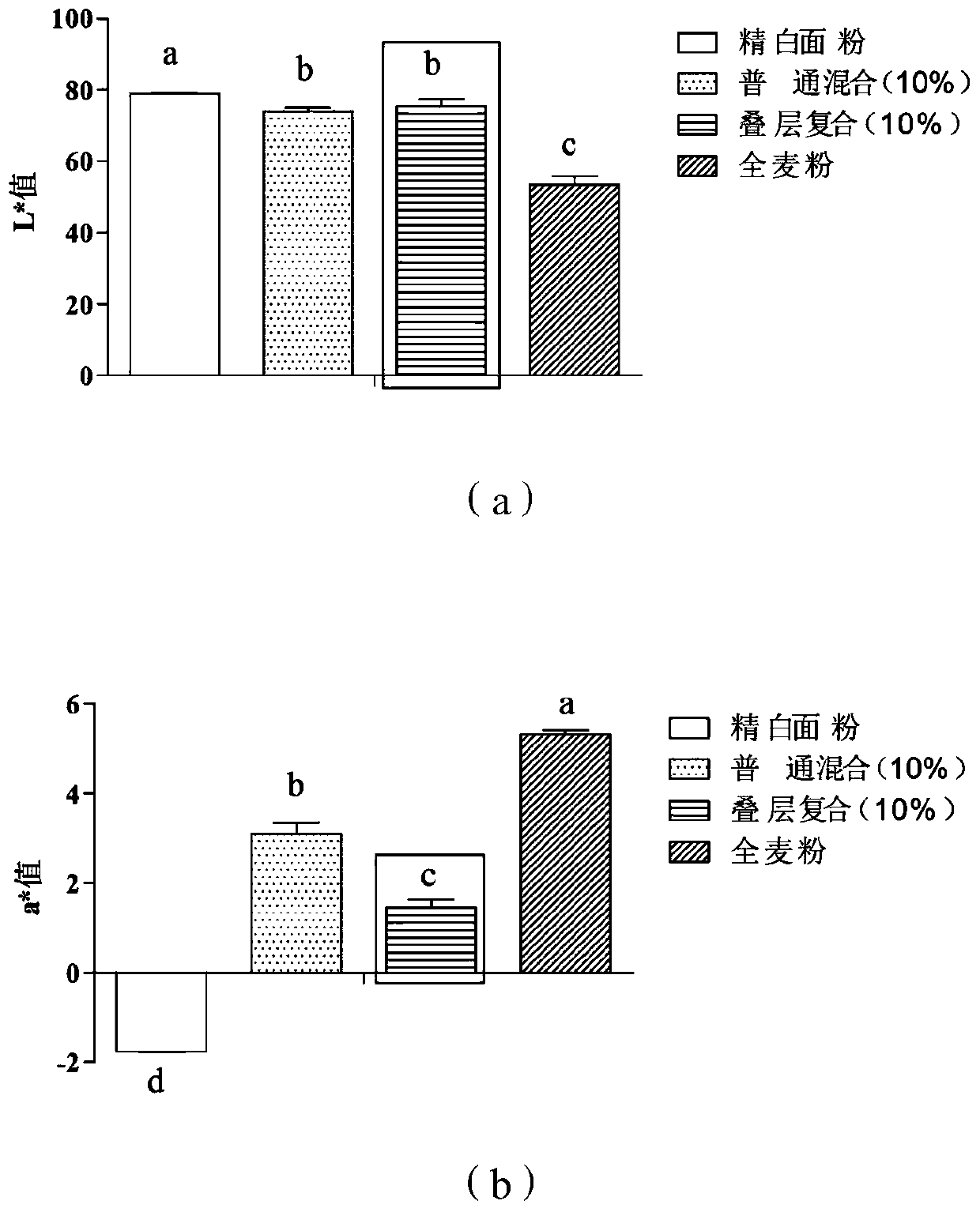

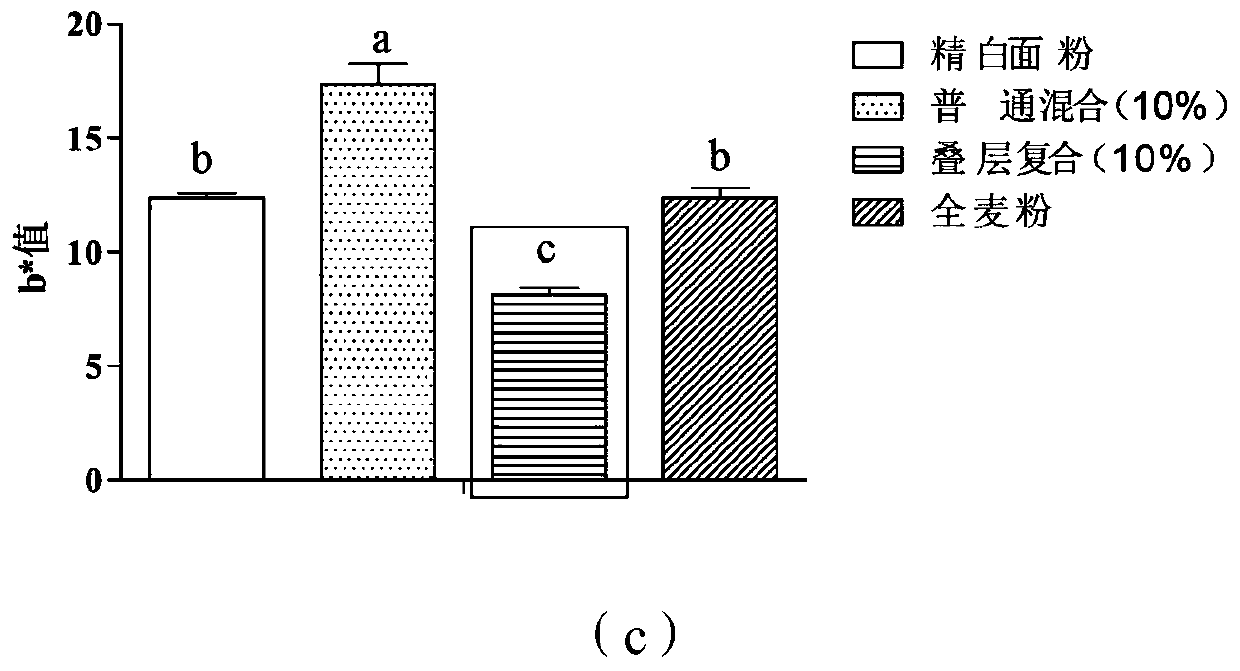

A technology of wheat aleurone layer and wheat flour, which is applied in the field of composite noodles and its preparation, can solve the problems of reddish and black color of noodle products, lack of firmness and smoothness, and large cooking loss, and achieve white color, moderate chewiness, Effect of Reducing Cooking Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

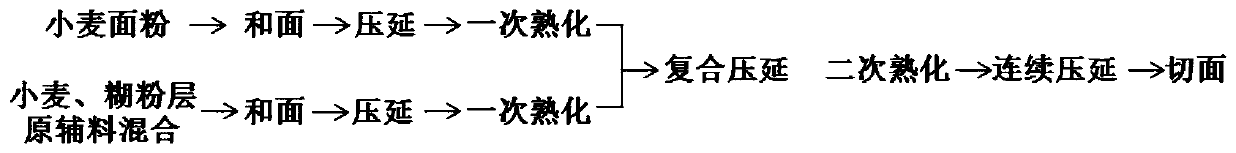

[0042] Present embodiment provides a kind of processing method of compound noodles, as figure 1 shown, including:

[0043] (1) Mix wheat flour and water in a mass ratio of 100:28 for vacuum kneading;

[0044] (2) Mix wheat flour and wheat aleurone layer at a mass ratio of 75:25, and then mix with water at a mass ratio of 100:37 to carry out vacuum kneading; the mass ratio of the dough A to the dough B is 4:1 ;

[0045] In step (1) and step (2), the vacuum kneading condition: the degree of vacuum is -60KPa, first stir at high speed for 5 minutes, then stir at low speed for 3 minutes;

[0046] (3) respectively calendering and primary curing;

[0047] Dividing the obtained dough A into two equal parts, respectively carrying out rolling and primary curing to obtain the first and third portions of dough; rolling and primary curing the obtained dough B to obtain the second portion of dough;

[0048] The number of rolling times of the first and third portions of dough is 5 times,...

Embodiment 2

[0058] The present embodiment provides a kind of processing method of composite noodles, comprising:

[0059] (1) Mix wheat flour and water at a mass ratio of 100:35 for vacuum kneading;

[0060] (2) Mix wheat flour and wheat aleurone layer at a mass ratio of 60:40, and then mix with water at a mass ratio of 100:42 to carry out vacuum kneading; the mass ratio of the dough A to the dough B is 6:1 ;

[0061] In step (1) and step (2), the vacuum kneading condition: the vacuum degree is -75KPa, first stir at high speed for 3 minutes, and then stir at low speed for 6 minutes;

[0062] (3) respectively calendering and primary curing;

[0063] Dividing the obtained dough A into two equal parts, respectively carrying out rolling and primary curing to obtain the first and third portions of dough; rolling and primary curing the obtained dough B to obtain the second portion of dough;

[0064] The number of rolling times of the first and third portions of dough is 4 times, and the roll...

Embodiment 3

[0075] The present embodiment provides a kind of processing method of composite noodles, comprising:

[0076] (1) Mix wheat flour and water at a mass ratio of 100:33 for vacuum kneading;

[0077] (2) Mix wheat flour and wheat aleurone layer at a mass ratio of 65:35, and then mix with water at a mass ratio of 100:39 to carry out vacuum kneading; the mass ratio of the dough A to the dough B is 3:1 ;

[0078] In step (1) and step (2), the vacuum kneading condition: the degree of vacuum is -100KPa, first stir at high speed for 4 minutes, and then stir at low speed for 7 minutes;

[0079] (3) respectively calendering and primary curing;

[0080] Dividing the obtained dough A into two equal parts, respectively carrying out rolling and primary curing to obtain the first and third portions of dough; rolling and primary curing the obtained dough B to obtain the second portion of dough;

[0081] The number of rolling times of the first and third portions of dough is 5 times, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com