Cabinet body of plate-type mortise-tenon assembly locking structure

A mortise and tenon and board-type technology, which is applied in the field of connection structure of board-type cabinet furniture, can solve problems such as shaking, increased shaking range, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

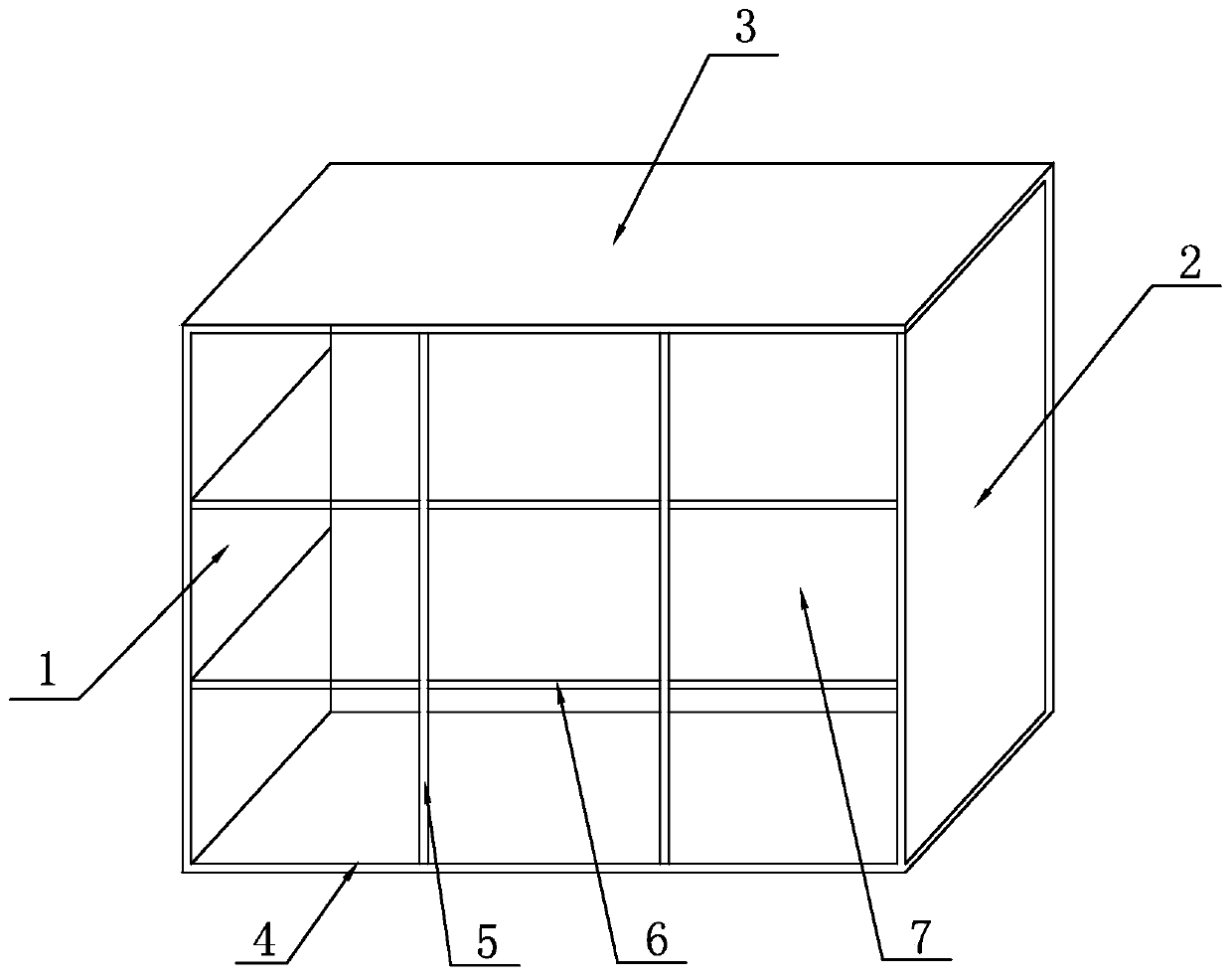

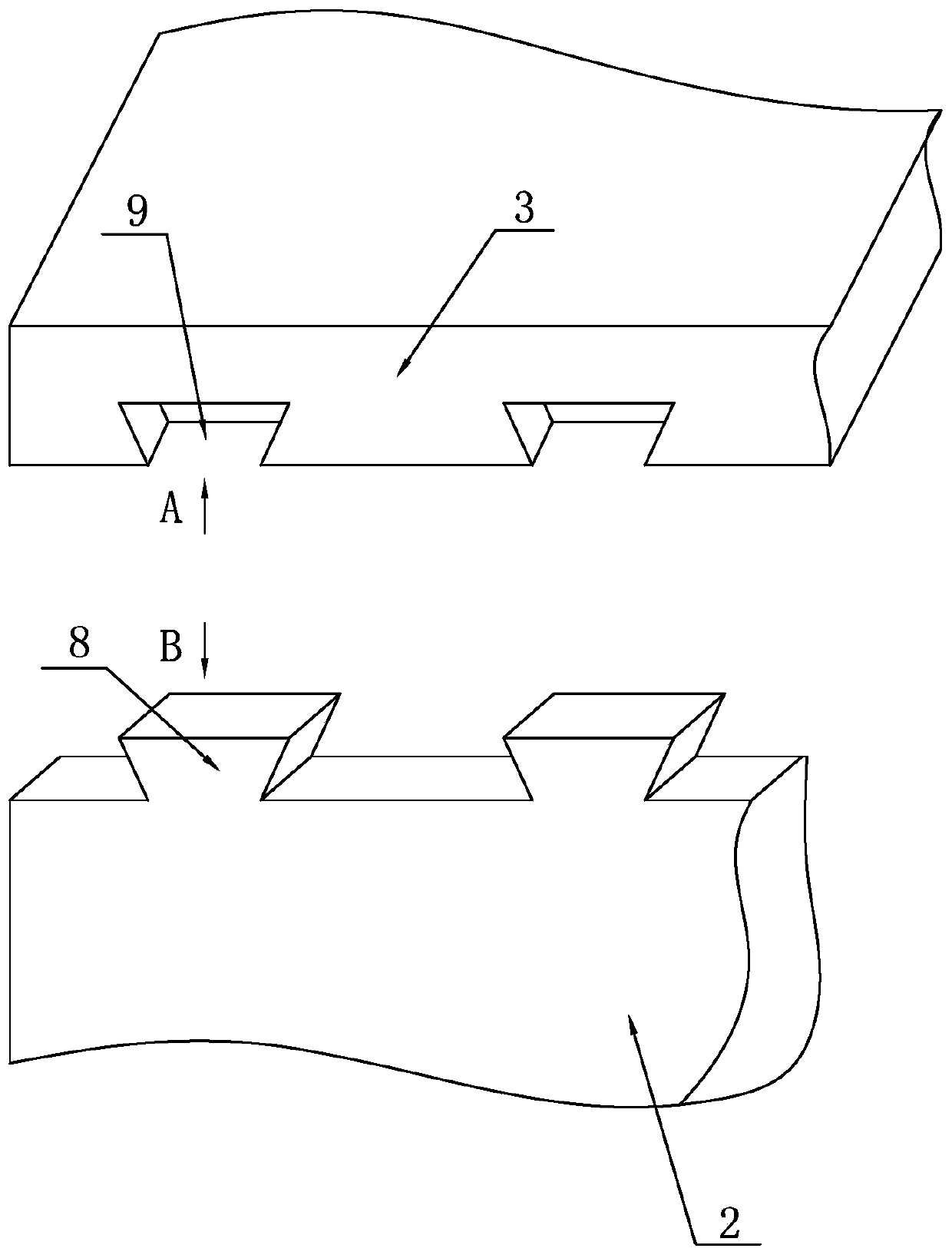

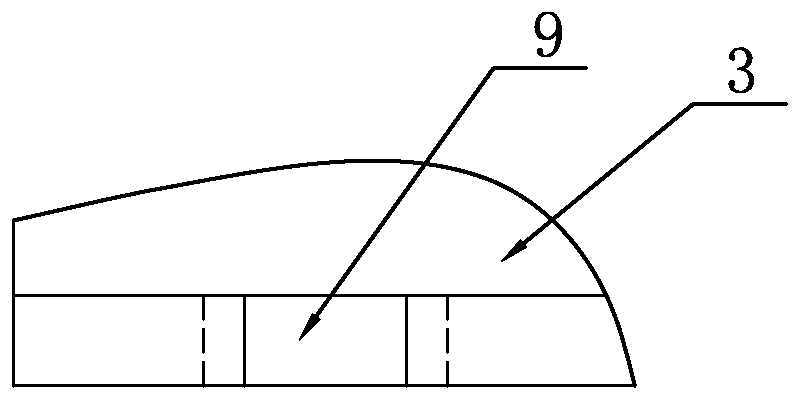

[0044] A panel type mortise and tenon assembly lock structure cabinet body, which is composed of a left side panel 1, a right side panel 2, a top panel 3, a bottom panel 4, two vertical partitions 5, two horizontal partitions 6 and a back panel 7 , the L-shaped fixed connection is realized between the left side plate 1, the right side plate 2, the top plate 3 and the bottom plate 4 through the dovetail tenon head 8 and the dovetail groove 9 mortise and tenon joint structure, and the height of the dovetail tenon head 8 is 80% of the plate thickness , the size, shape and depth of the dovetail groove 9 correspond to the dovetail tenon head 8, and the four are assembled into a cabinet frame; between the vertical partition 5 and the top board 3, the bottom board 4, the horizontal partition 6 and the left side board 1, The T-shaped fixed connection is realized between the right side panels 2 through the seat and gradually tightening plug-in engagement structure formed by the large an...

Embodiment 2

[0048] Embodiment 2: The difference from Embodiment 1 is that in the L-shaped fixed connection, two adjacent boards are spliced at a 45-degree diagonal surface at the diagonal connection, so that the connection between the two cannot be seen from the outside. Mortise and tenon joint structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com