A device and method for preparing high-purity titanium metal powder by continuous electrolysis

A kind of metal titanium powder, high-purity technology, applied in the direction of electrolysis components, electrolysis process, electrodes, etc., can solve the problems of lower production efficiency, lower quality, high raw material cost, etc., and achieve high production efficiency, increase production efficiency, and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

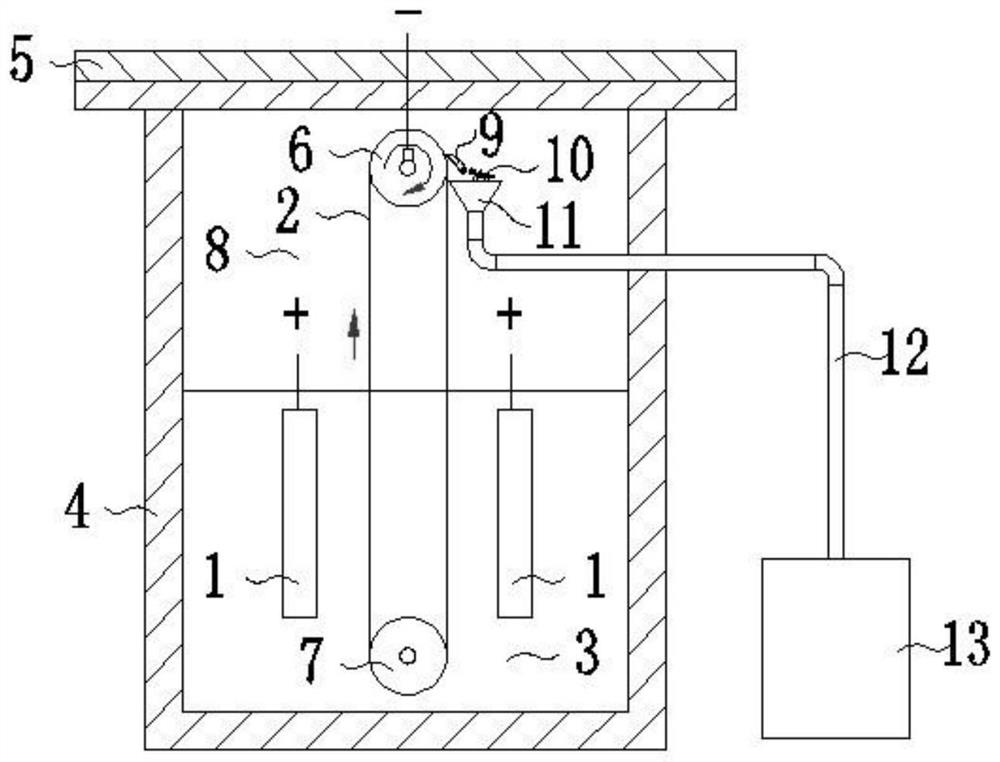

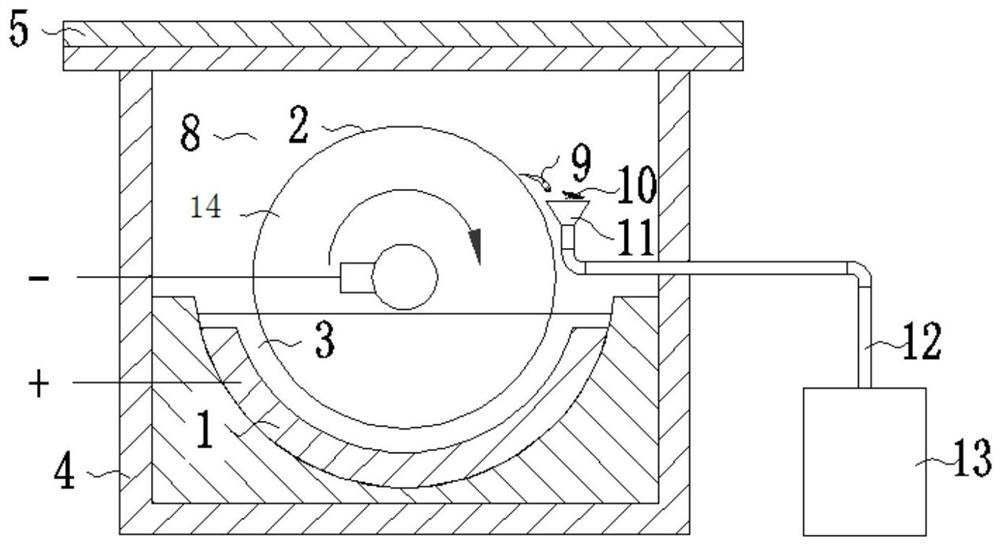

[0050] use figure 1 As shown in the molten salt electrolysis device configured with a conveyor belt type rotary cathode, a titanium-containing conductive ceramic anode 1 prepared by the above method is selected, and the chemical composition is TiC 0.33 o 0.67 . The cathode 2 (belt type) is SUS304 stainless steel with a thickness of 0.5 mm. With LiCl-NaCl-KCl-TiCl 2 -TiCl 3 The molten salt is the electrolyte, and the content of titanium ions is 4%wt. The inert gas atmosphere 8 in the electrolytic cell is protected by argon, and the electrolysis is carried out at 550°C. The electrolytic cell voltage is 4.1V, and the cathode current density is 0.3A / cm 2 . The rotation rate of the cathode 2 is 0.2m / s. After 12 hours of electrolysis, the metal titanium powder at the bottom of the inert gas atmosphere / vacuum environment storage tank 13 is passed through the metal titanium mesh filter mechanism to recover the molten salt. Next, the filtered titanium metal powder is cooled to ...

Embodiment 2~6

[0053] Change the transmission rate of negative electrode 2 (belt type), all the other experimental conditions are identical with embodiment 1, and the average particle diameter result of metal titanium powder that obtains is as follows,

[0054] Example Speed of rotating cathode (m / s) Average particle size of titanium metal powder (μm) 2 0.05 487 3 0.1 135 4 0.5 30 5 1 13 6 2 3.5

Embodiment 7

[0056] use figure 1 The shown molten salt electrolysis device is configured with a conveyor-belt rotary cathode, and the chemical composition is TiC 0.2 o 0.4 N 0.4 Titanium-containing conductive ceramic anode. The conveyor belt rotating cathode is a Ti metal belt with a thickness of 0.3 mm. with Ca 2 Cl-NaCl-KCl-TiCl 2 The molten salt is the electrolyte, and the content of titanium ions is 3%wt. Electrolysis was carried out at 670°C. The electrolytic cell voltage is 3.6V, and the cathode current density is 0.1A / cm 2 . All the other experimental conditions were consistent with Example 1.

[0057] The average particle diameter of the obtained metal titanium powder was 55 μm, and the elemental analysis results were: Ti: 99.50%, C: 0.05%, O: 0.15%, Fe: 0.07%. The yield of Ti element is 97%, and the current efficiency of the cathode is 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com