Roller conveying device for flexible belt materials

A conveying device and roller technology, which is used in transportation and packaging, coiling strips, thin material handling, etc., can solve problems such as jumping and slippage of flexible strip materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

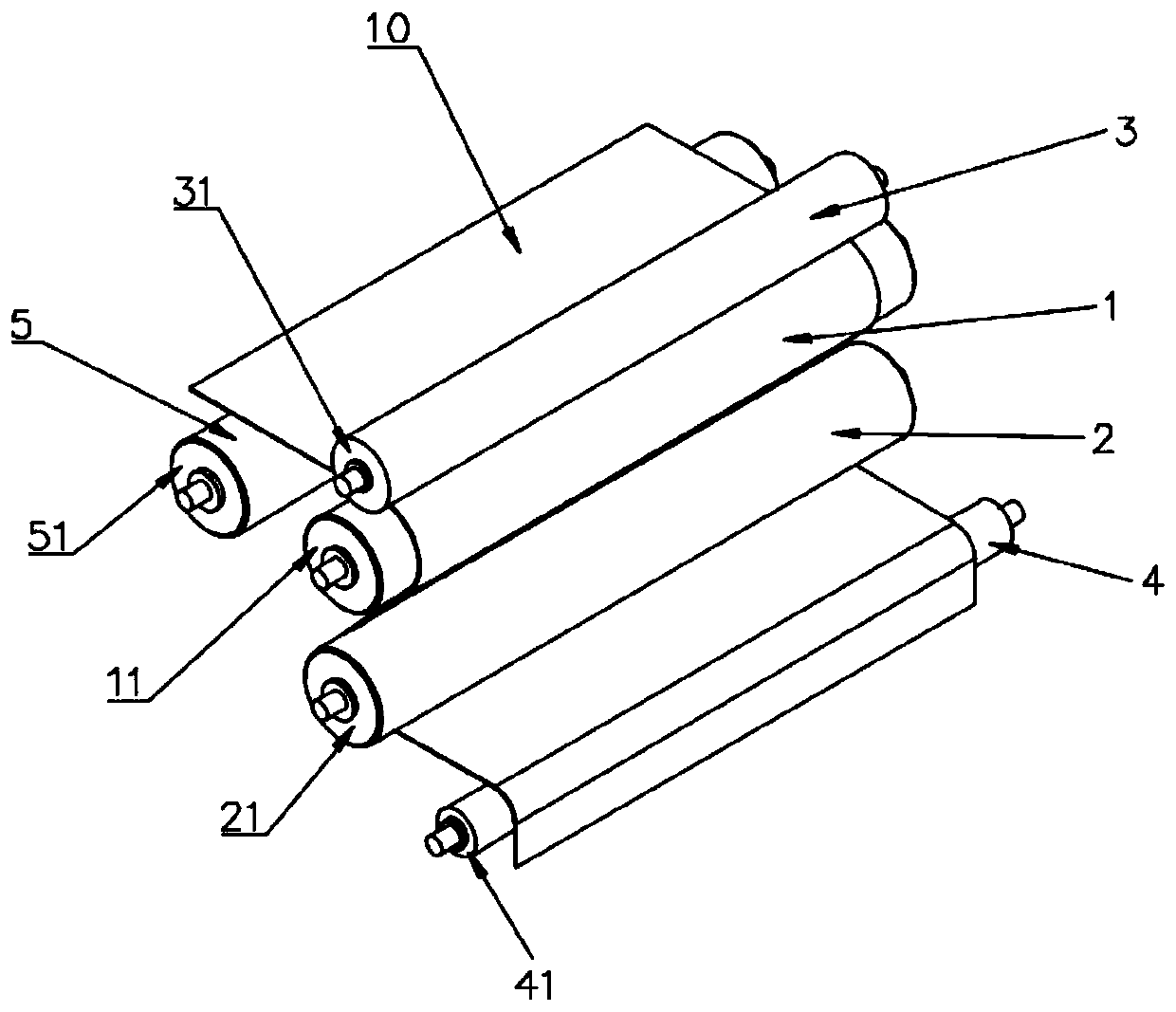

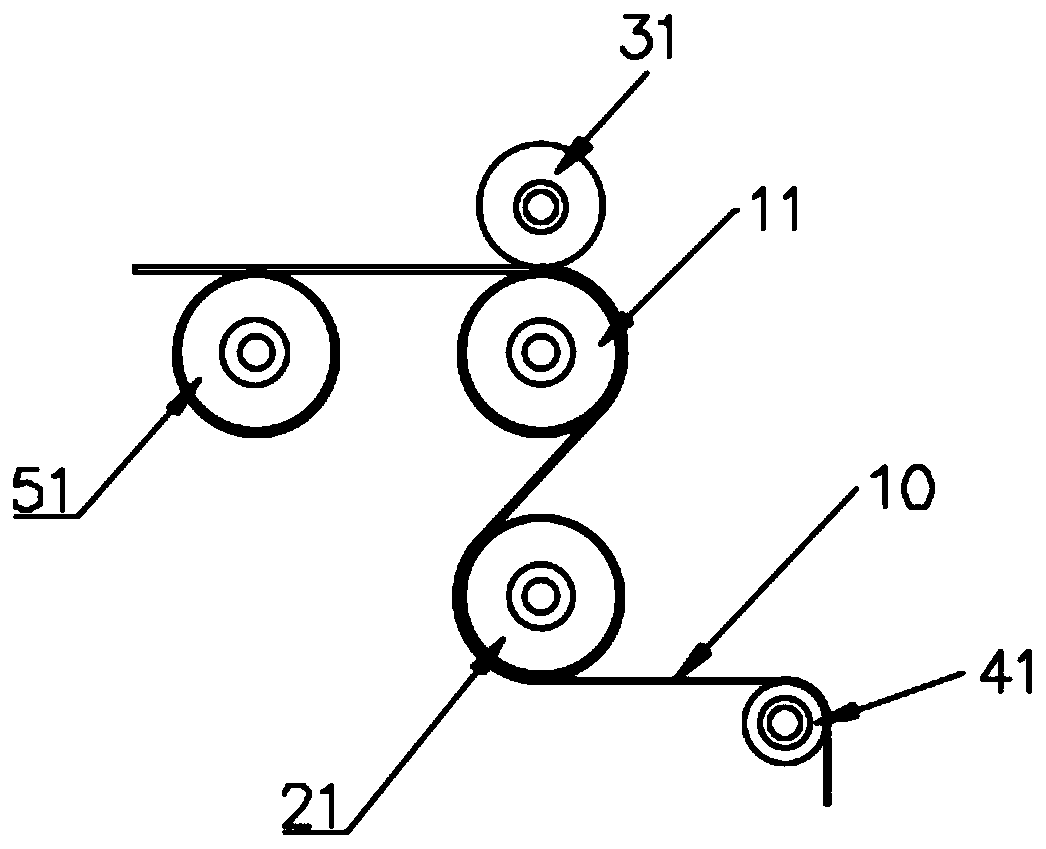

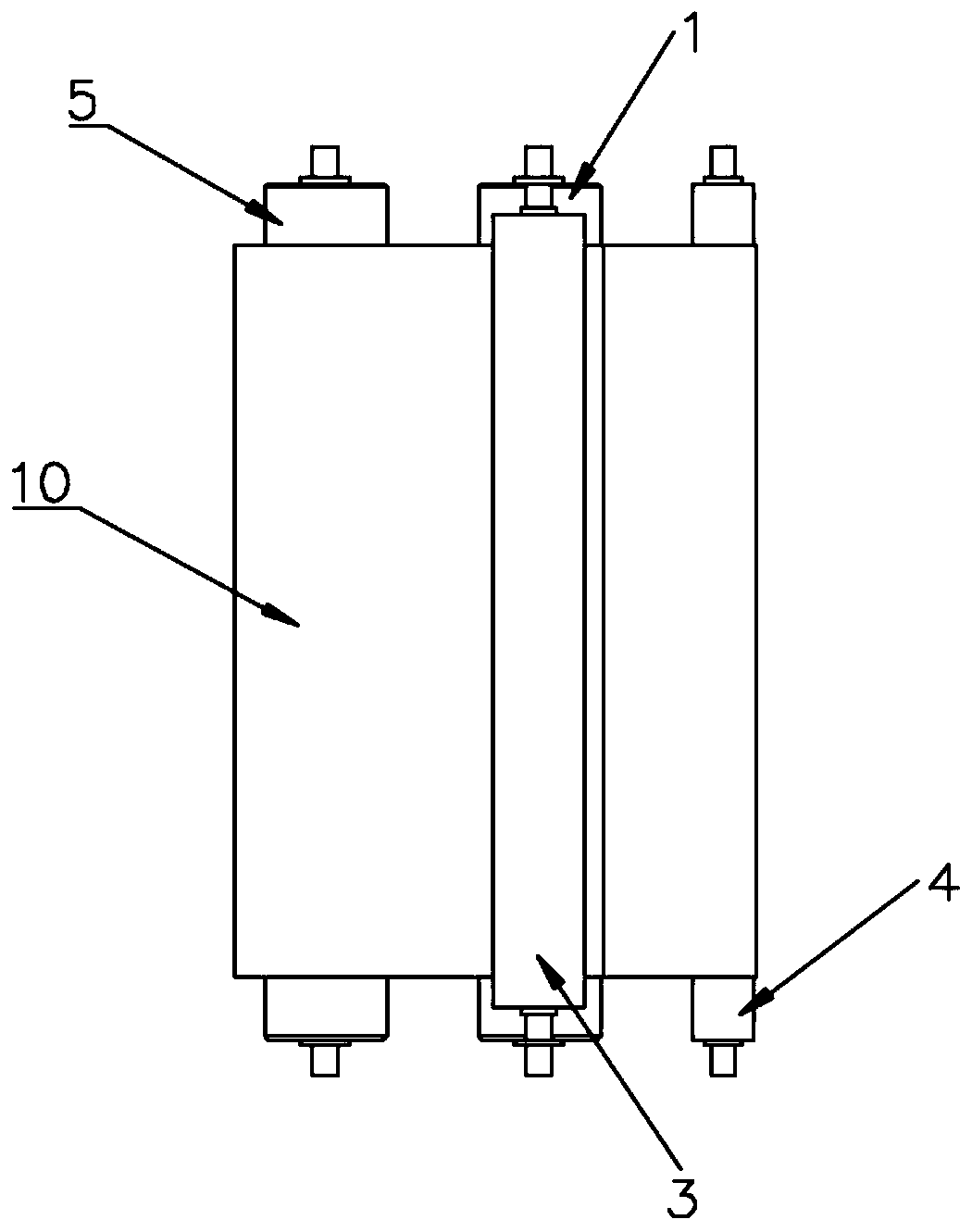

[0022] Such as Figure 1 to Figure 3 As shown, the present invention provides a preferred embodiment of a roller conveyor for flexible web material.

[0023] refer to figure 1 , a roller conveying device for a flexible strip-shaped material 10, the roller conveying device is used for conveying a flexible strip-shaped material 10, the flexible strip-shaped material 10 refers to that it can be easily deformed after being given an action force, but will not Damaged materials such as plastic film, paper, and cloth.

[0024] Specifically, refer to figure 1 As shown in Fig. 3, the roller conveying device includes a main driving roller 1, a slave driving roller 2, a pinch roller 3 and a driving mechanism connected to the main driving roller 1 and / or the slave driving roller 2, That is to say, the driving mechanism is drivingly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com