Brushed-metal composite board

A metal wire drawing and composite sheet technology, which is applied to metal layered products, synthetic resin layered products, layered products, etc., can solve the problems of no insulation layer and inability to apply thermal insulation, etc., and achieves low cost and dosage. Less and more economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

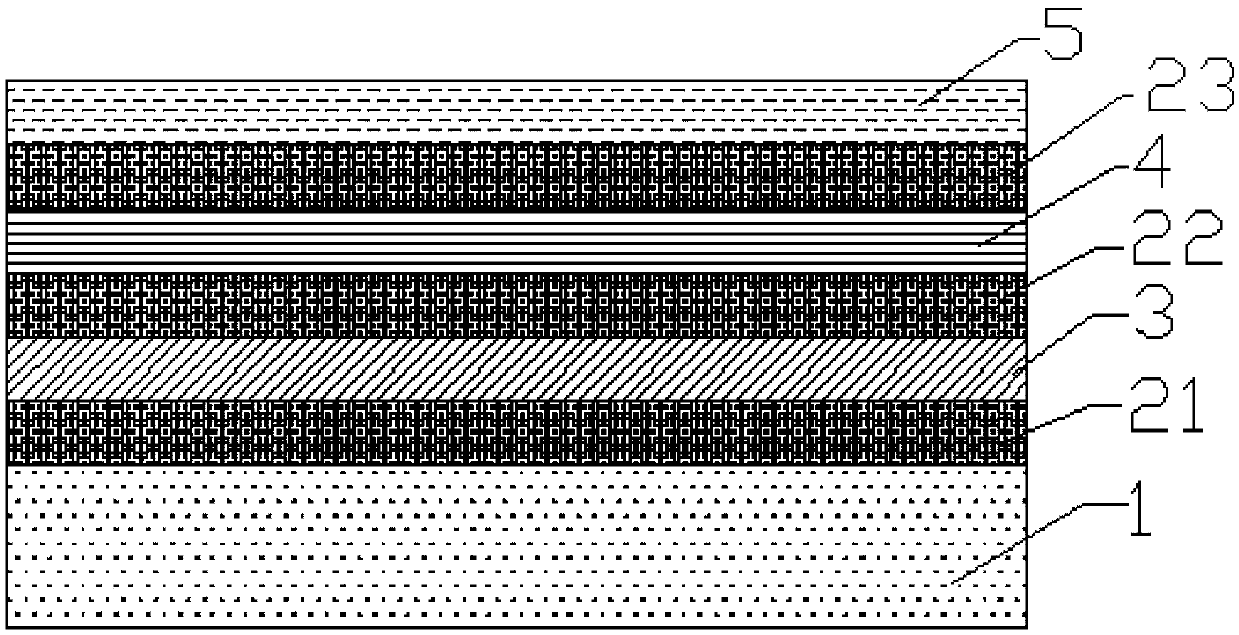

[0011] Such as figure 1 As shown, a metal wire drawing composite board comprises a plastic substrate layer 1, a bonding layer 1 21, a heat insulation layer 3, a bonding layer 2 22, a metal wire drawing layer 4, a bonding layer 3 23, and a protective film layer 5. The above layers are connected in sequence; the plastic substrate layer 1 is a PP or PE layer, the heat insulation layer 3 is an airgel felt layer or a vacuum board layer, and the metal wire drawing layer 4 is a wire drawing aluminum foil layer and an oxidation treatment film layer The composite structure, the protective film layer 5 is a baking varnish layer, and the adhesive layers one 21, two 22, and three 23 can be high-temperature-resistant double-sided adhesive layers.

[0012] The thickness of the plastic substrate layer 1 is 7 mm, the thickness of the heat insulation layer 3 is 3 mm, the thickness of the metal wire drawing layer 4 is 2 mm, the thickness of the protective film layer 5 is 1 mm, and the overall t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com