Protection rod assembly device for folding antennas

A technology for folding antennas and assembling devices, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of less automation equipment, complex structure, manual assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

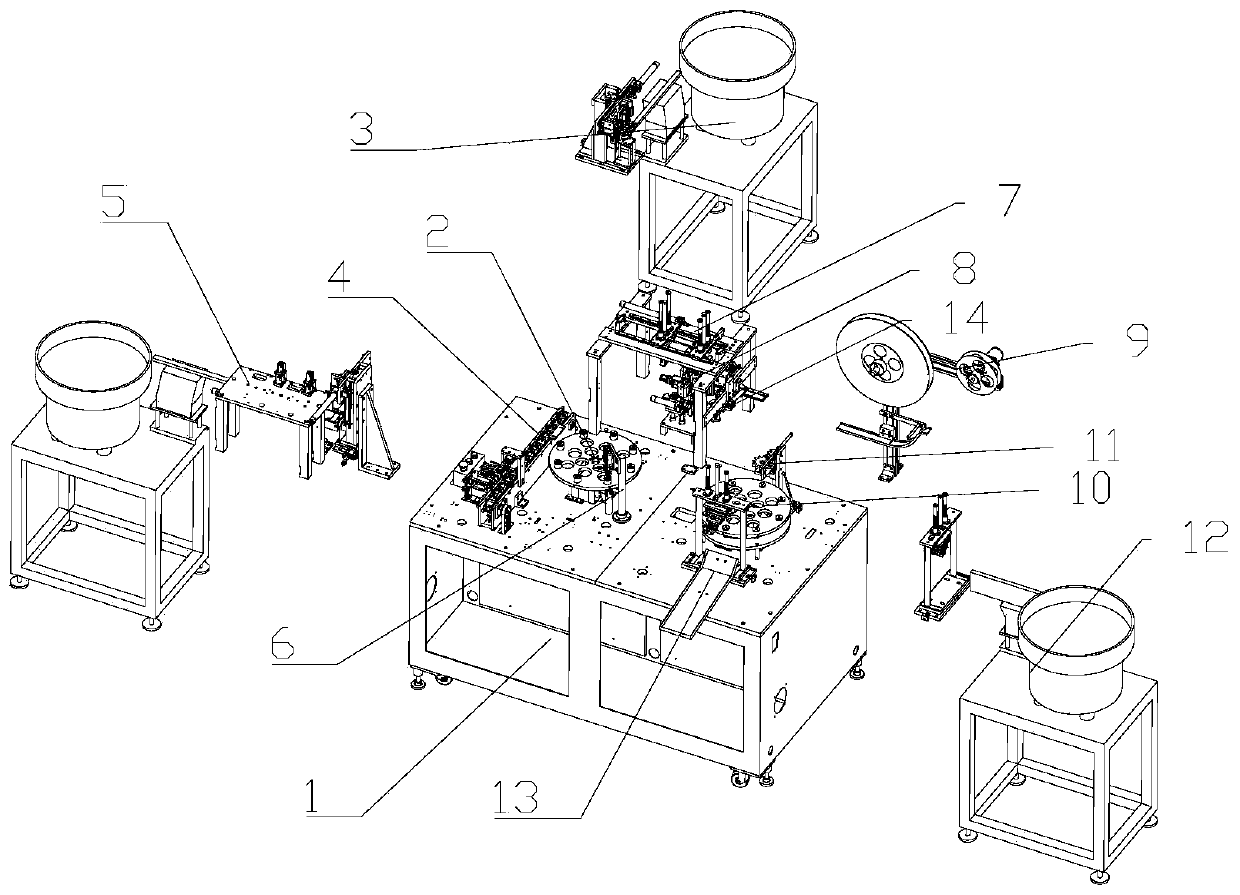

[0037] Such as figure 1 As shown, the automatic assembly equipment for a folded antenna includes a frame 1 and a first turntable device 2 installed on it, a rotating member feeding device 3, an antenna core feeding and transferring device 4, and a sma joint feeding and assembling device 5. Pressing device 6, handling device 7, copper sheet pressing device 8, copper sheet feeding device 9, second turntable device 10, positioning device 11, antenna guard rod feeding device 12, finished product unloading device 13 and guard rod Assembly device 14; rotating member feeding device 3, antenna core feeding and circulation device 4, sma joint feeding assembly device 5 and pressing device 6 are connected and installed on the first turntable device 2; the handling device 7 is installed on the Between the first turntable device 2 and the second turntable device 10, the copper sheet pressing device 8 is located below the conveying device 7, and the output end of the copper sheet feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com