Sewage settling tank

A sedimentation tank and sewage technology, which is applied in the fields of sedimentation separation, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Not high problems, to achieve the effect of improving volume and accelerating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

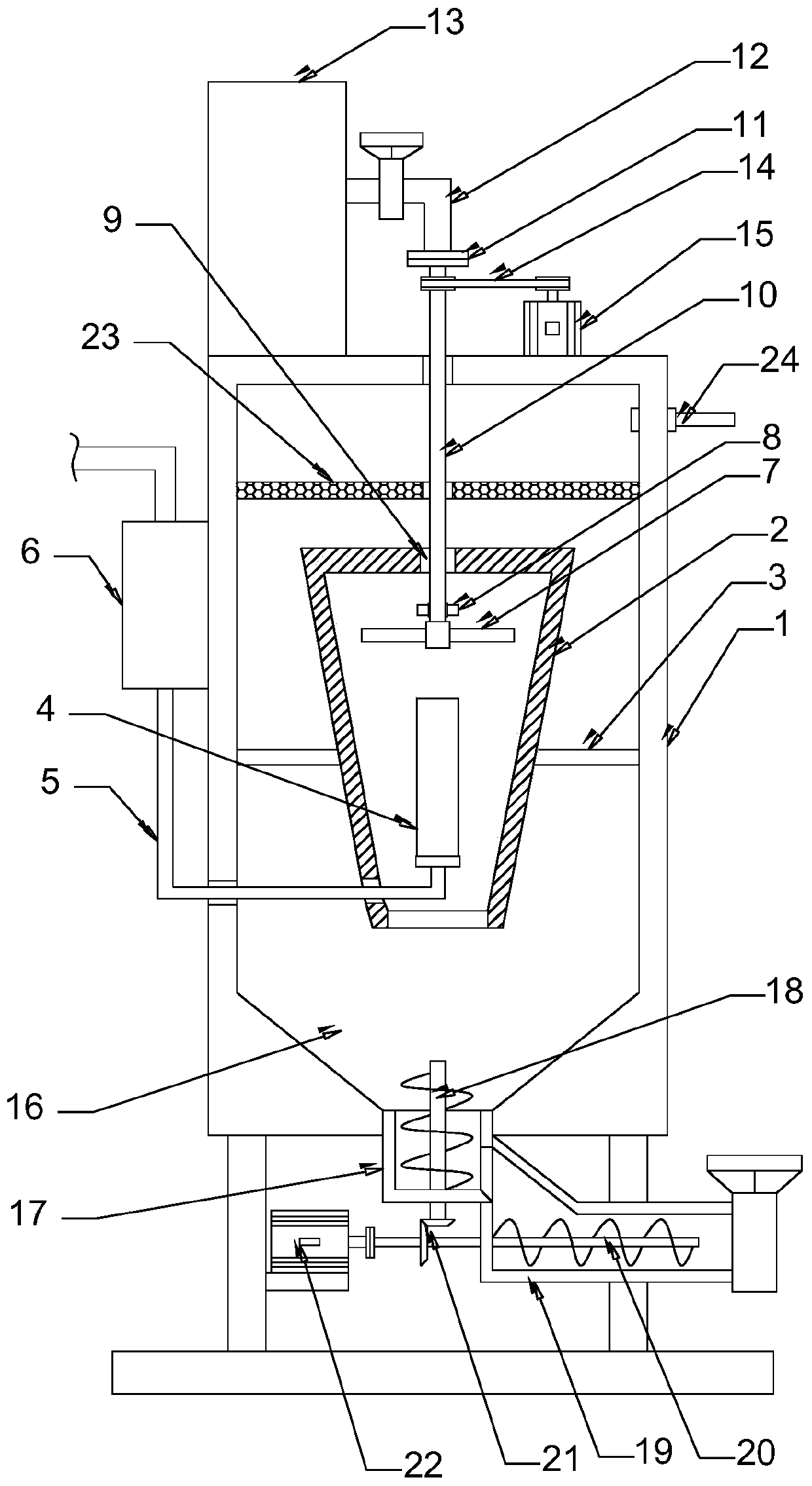

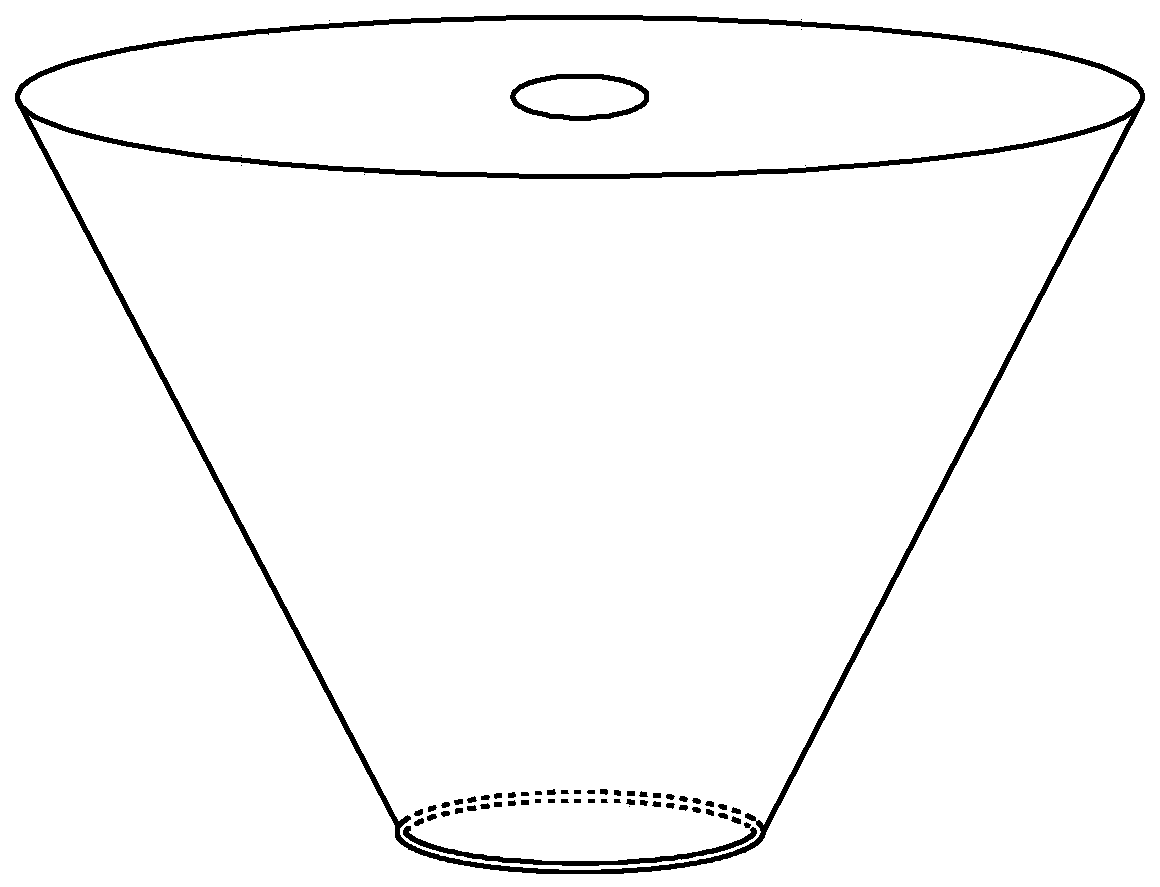

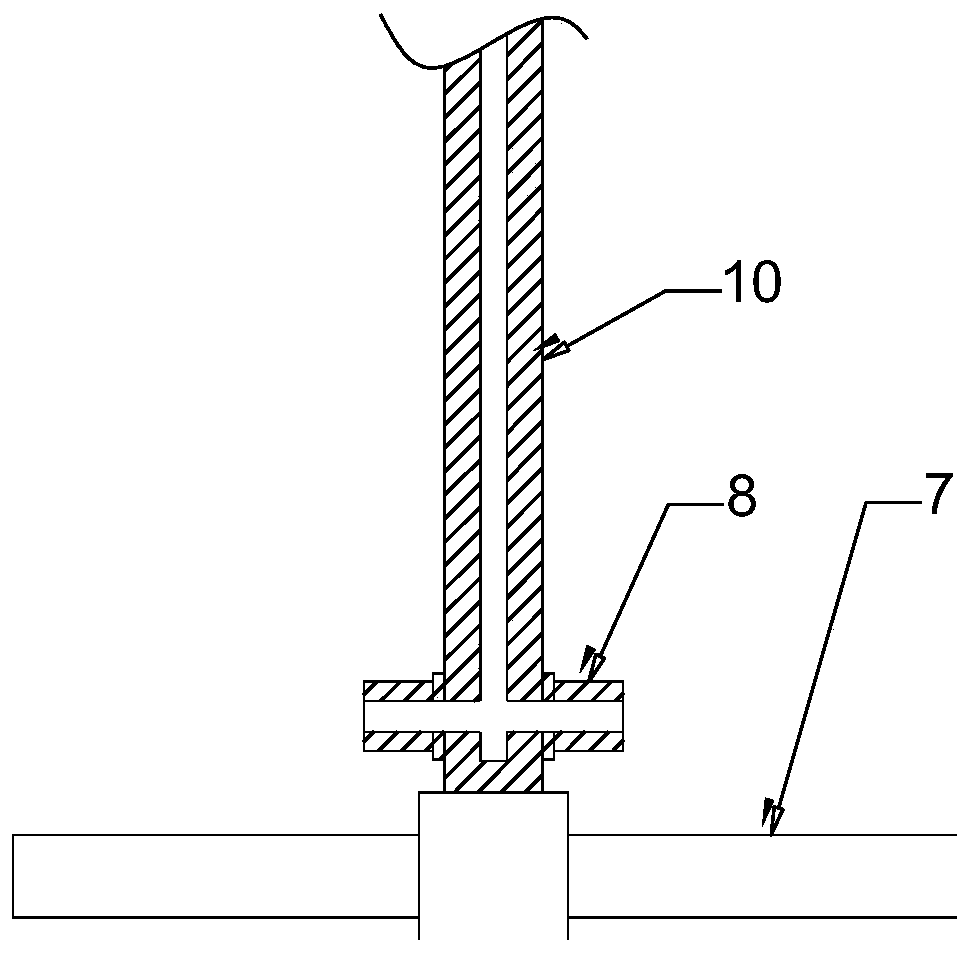

[0020] see Figure 1~3 , in an embodiment of the present invention, a sewage settling tank includes a tank body 1; a mixing cylinder 2 is arranged in the tank body 1, and the mixing cylinder 2 is located at the central axis of the tank body 1, and the mixing cylinder 2 is a conical shape with an open lower end. The mixing cylinder 2 is fixedly connected to the inner wall of the tank body 1 through the installation rod 3; the central axis of the mixing cylinder 2 is provided with a vertical outlet pipe 4, and the vertical outlet pipe 4 is connected to the water inlet pump 6 through the water inlet pipe 5, and the water inlet pump 6 communicates with the external waste water tank to be treated, and the water inlet pump 6 is electrically connected with the external power supply, and the water inlet pump 6 pumps the waste water through the water inlet pipe 5 to the vertical outlet pipe 4 in the mixing cylinder 2 for discharge; the vertical outlet pipe 4 The upper end is provided w...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that: the lower end of the sedimentation chamber 16 is connected with a feeding pipe 17, and the side of the feeding pipe 17 is connected with a mud outlet pipe 19, and the mud outlet pipe 19 is provided with a manual valve. There is a vertical spiral blade roller 18 inside, and a horizontal spiral blade roller 20 is arranged in the mud outlet pipe 19. The rotating shaft of the vertical spiral blade roller 18 and the rotating shaft of the horizontal spiral blade roller 20 extend in reverse and are connected by a transmission gear set 21. The transmission gear set 21 includes a group of bevel gears that are vertically cut and engaged with each other; the rotating shaft of the horizontal spiral blade roller 20 is connected with a second drive motor 22 through a coupling, and the second drive motor 22 is electrically connected with an external power supply. The drive motor 22 drives the vertical helical blade roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com