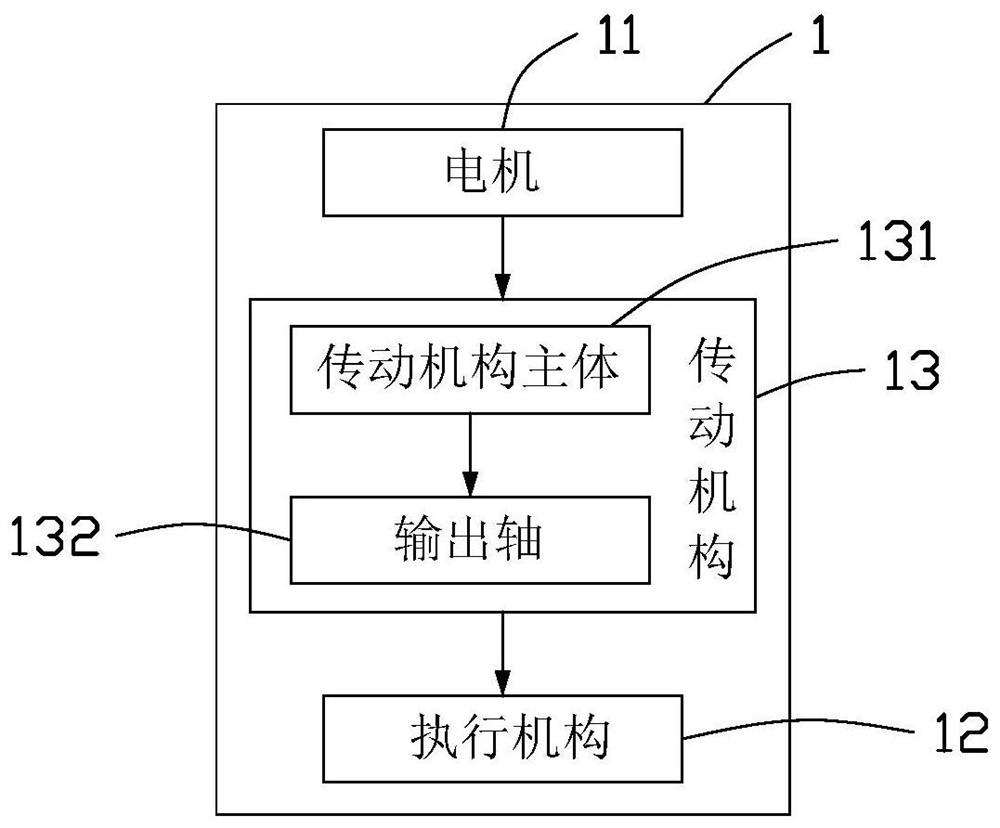

Actuator and its transmission mechanism

A technology of an actuator and a transmission mechanism, which is used in electromechanical devices, electric components, and mechanical energy control, etc., can solve the problems affecting the strength of the nut and the stopper sleeve, generate noise, and shake the stopper sleeve, so as to strengthen the strength, improve the The effect of shaking and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

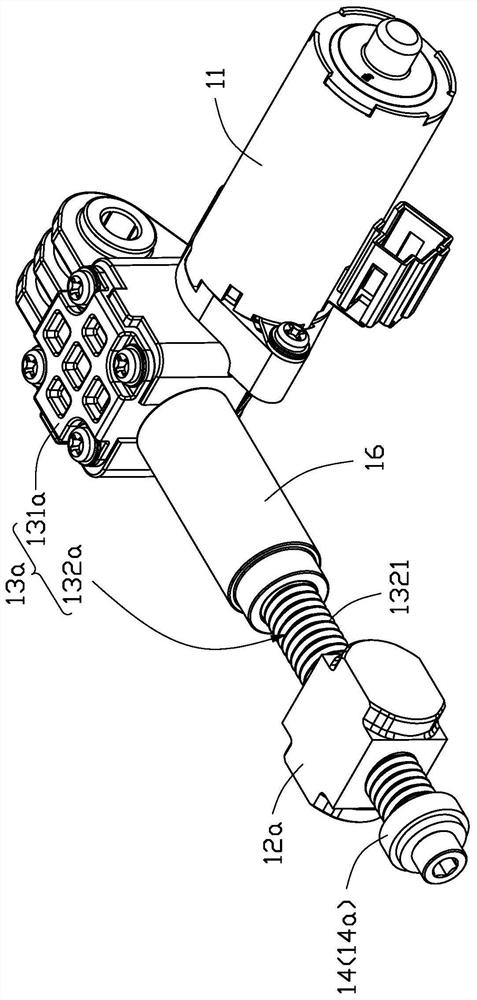

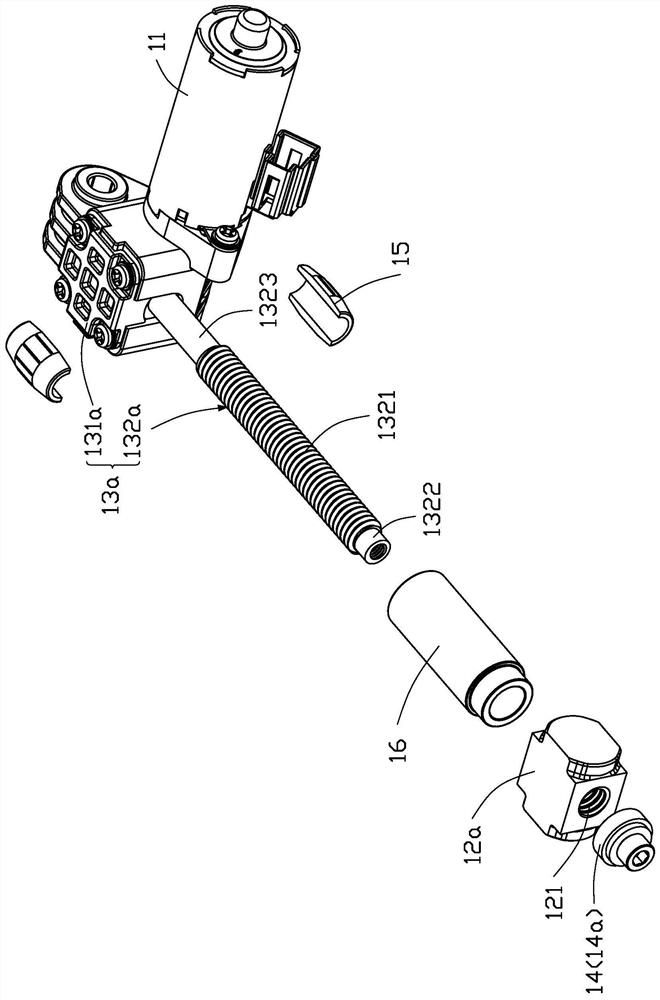

[0028] Various embodiments of the present invention will be described with reference to the accompanying drawings. In the specification and drawings, elements having similar structures or functions will be represented by the same component symbol. It will be appreciated that the accompanying drawings are merely illustrative of reference and illustrative purposes only and is not intended to limit the invention. The dimensions shown in the drawings are merely intended to be clearly described, and not to limit the proportional relationship or to illustrate the invention, the scope of the present invention is not limited. All technical and scientific terms used herein are commonly understood by those skilled in the art of the present invention, unless otherwise defined.

[0029] It should be noted that the component is referred to as "fixed to", "mounted" another component, which can be directly in another component or may exist in the hidden component. When a component is considered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com