SOI substrate OLED micro-display device having reflective isolation layer

A technology for microdisplay devices and isolation layers, which is applied in the manufacture of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of pixel cross-color and small device size, and achieves reduction of cross-color, lower product cost, and improved Display quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

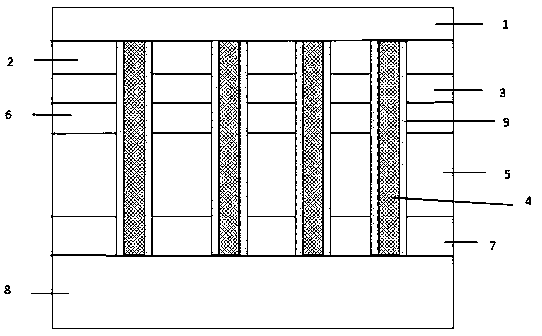

[0010] Describe in detail below in conjunction with the structure of the present invention: figure 1 Among them, an SOI-based OLED microdisplay device with a reflective isolation layer, including a cover glass (1), a color photoresist (2), an encapsulation film layer (3), a transparent cathode (6), and an OLED light-emitting layer (5 ), pixel anode (7), reflective isolation layer (4), SOI substrate (8), silicon dioxide oxide layer (9). It is characterized in that the reflective isolation layer (4) is grown in the gap between the pixel anodes (7) by using Cu metal by electroplating, and the reflective isolation layer (4) is wrapped by a layer of silicon dioxide oxide layer (9). Its manufacturing method Include the following steps:

[0011] 1. Fabricate the pixel anode (7) on the SOI substrate;

[0012] 2. A Cu reflective isolation layer (4) with a thickness of 200nm is electroplated and grown by Damascus process at the interval of the pixel anode (7);

[0013] 3. A silicon d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com