Coaxial double-waveguide optical fiber capable of generating vortex light and toroidal field, and preparation method of coaxial double-waveguide optical fiber

A dual-waveguide, vortex light technology, applied in the direction of optical waveguide light guide, cladding optical fiber, etc., can solve the problems such as difficulties in preparing optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

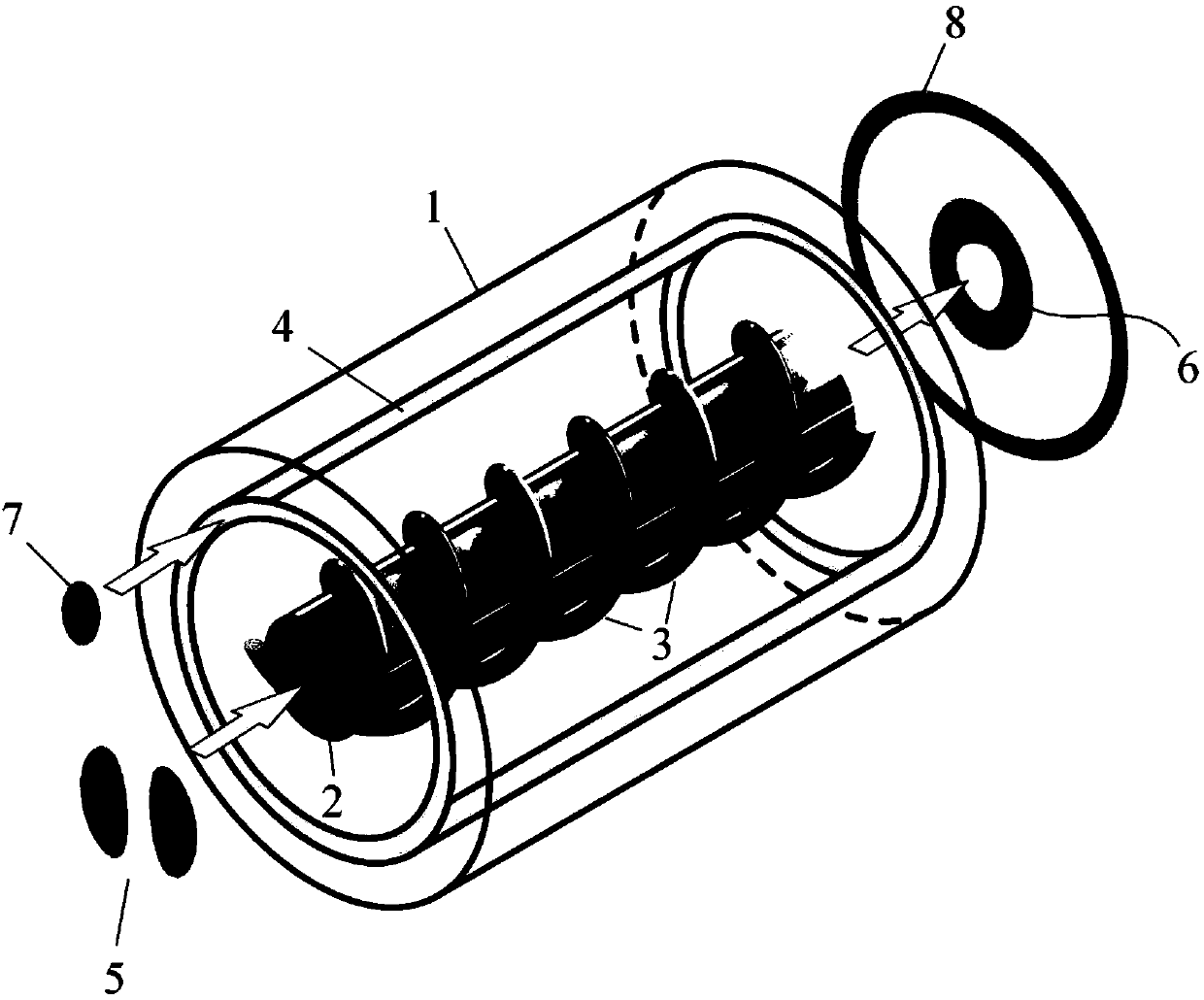

[0024] The preparation process of the coaxial dual waveguide fiber can be divided into the following two steps (see Figure 5 with Image 6 ):

[0025] Step 1: Coaxial dual waveguide fiber preform preparation (see Figure 5 ). First adopt the MCVD method to prepare a hollow annular core optical fiber preform member whose inner wall contains a central hole 9 and an inner annular core layer 10; Embed a small core rod 13 in the microhole 12, and finally embed the whole insert into a hollow ring-core optical fiber preform member to form a new optical fiber preform 14.

[0026] Step 2: Place the prepared optical fiber preform 14 on the optical fiber drawing tower and fix it on the rotating motor 15. The optical fiber preform 14 enters the heating furnace 16 to heat and melt, and under the vertical traction force 17 and the torsion force provided by the rotating motor 7 Under the combined action of rotating and drawing, the coaxial dual waveguide optical fiber 18 is finally draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com