Sealing device for ultra-deep water marine working ship sea chest

A technology of submarine valve box and sealing device, which is applied in the direction of pipelines, hulls, ship parts, etc. used for emptying/ballasting, and can solve the problems of high cost and seawater failure of seawater valve boxes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

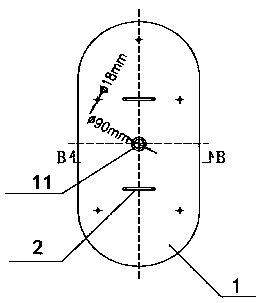

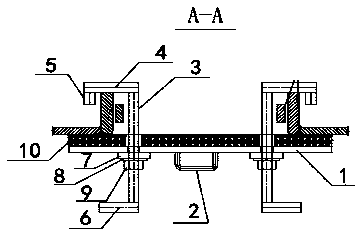

[0014] Such as Figure 1 to Figure 4 As shown, the sealing device for the subsea valve box of an ultra-deep sea work vessel includes a plugging blind plate 1, a handrail 2, a screw rod 3, a vertical stop bar 4, a horizontal stop bar 5, and a hand-held bar 6 , sealing rubber 10 and pumping valve 11, a small round hole is arranged on the plugging blind plate 1, and a large round hole is arranged in the middle, the handrail 2 is fixed on one side of the blocking blind plate 1, and the sealing rubber 10 is arranged on the sealing blind plate 1 On the other side, the screw rod 3, the vertical stop round steel 4 and the horizontal stop round steel 5 are welded together to form an integrated structure, and the integrated structure formed by the screw rod 3, the vertical stop round steel 4 and the horizontal stop round steel 5 is inserted into the In the small round hole on the plugging blind plate 1, the hand-held round steel 6 is welded with the screw rod 3 to form a rotating C-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com