A drug packaging equipment

A technology for packaging equipment and medicines, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems such as high cost and complex structure, and achieve the effects of low manufacturing cost, simple use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

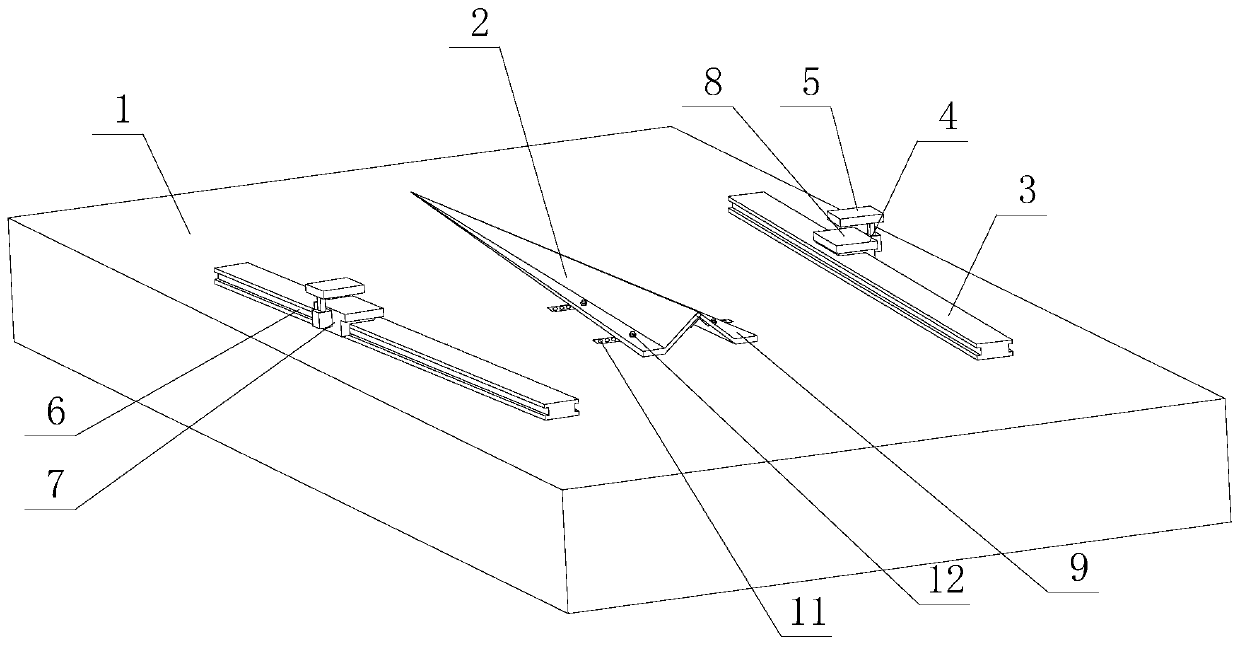

[0048] Such as Figure 1 to Figure 4 The medicine packaging equipment shown includes a cardboard hemming device, and the cardboard hemming device includes a hemming workbench 1 and a hemming plate 2 installed on the hemming workbench 1, and the hemming plate 2 A straight top is also provided above the top, and a driving device for driving the cardboard to interact with the top is also included. The folding board 2 is two pieces, and the two folding boards 2 are in a plane-symmetrical relationship. And the symmetrical planes of the two flanging plates 2 are perpendicular to the table top of the flanging workbench 1;

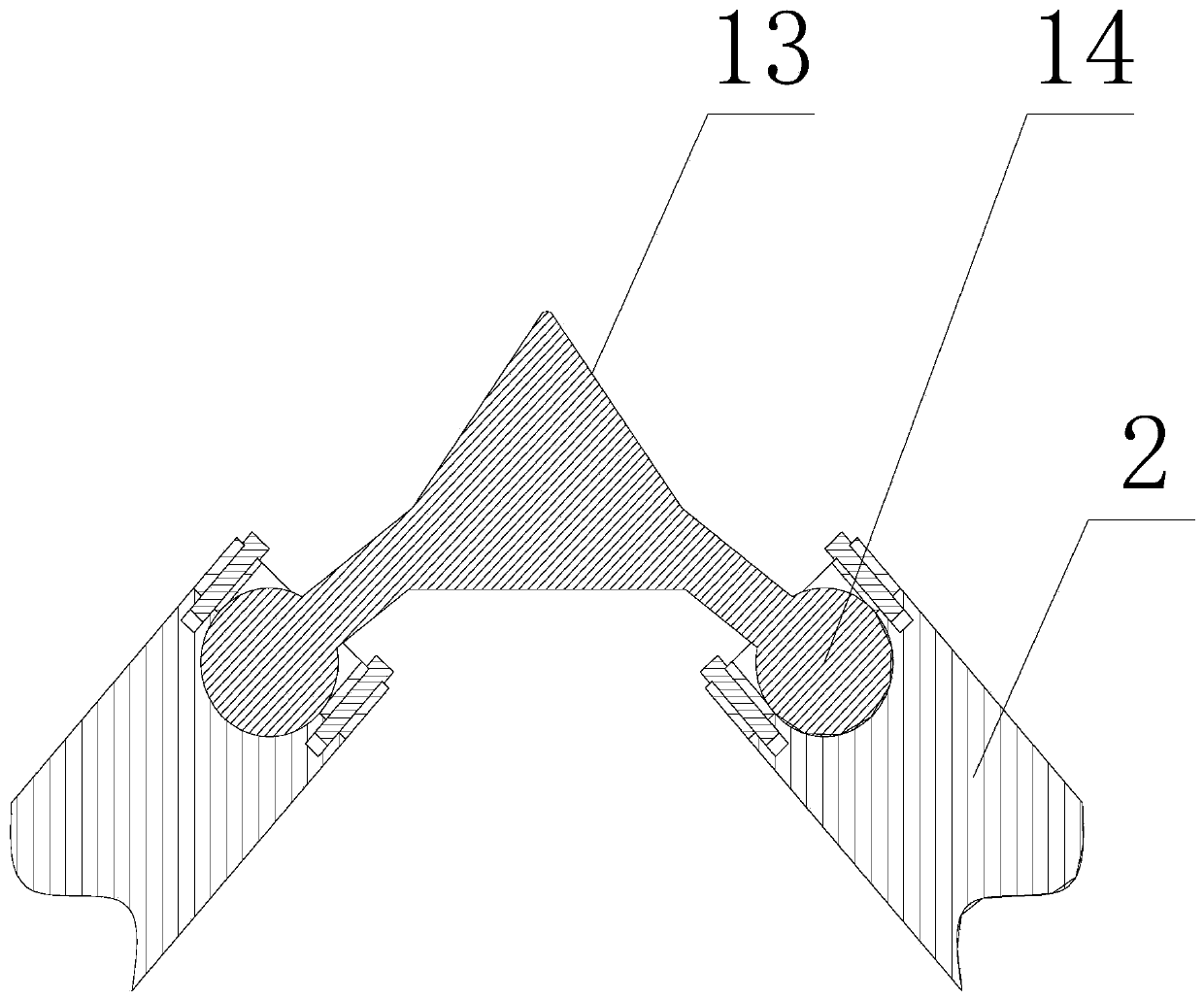

[0049] The upper ends of the two flanging plates 2 are close to each other, and the upper ends of the two flanging plates 2 are parallel to each other;

[0050] It also includes a strip-shaped hem strip 13, the top of which is the top of the hem strip 13, and the left and right sides of the lower end of the hem strip 13 are provided with hinge shafts 14, and the ...

Embodiment 2

[0060] This embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 4 As shown, as the specific installation method of the hemming plate 2 on the hemming workbench 1, it is set as follows: two mounting wing plates 9 are also included, and a mounting wing plate 9 is connected to the bottom end of each hemming plate 2 respectively, and The installation wing 9 connected to the left side flange 2 is located on the left side of the flange 2, and the installation wing 9 connected to the right side flange 2 is located on the right side of the flange 2;

[0061] Each mounting flange 9 is provided with a first bolt hole 10;

[0062] A second bolt hole 11 is also provided on the hemming workbench 1;

[0063] Each mounting wing plate 9 is bolted to the hemming workbench 1 through tightening bolts 12 , and the first bolt holes 10 and the second bolt holes 11 are the bolt holes of the tightening bolts 12 . This solution provides an easy-to-implement and conveni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com