A method for designing lateral stiffness of an aircraft large-opening structure

A technology of lateral stiffness and design method, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problem of no theoretical basis for the design of large opening fuselage, and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

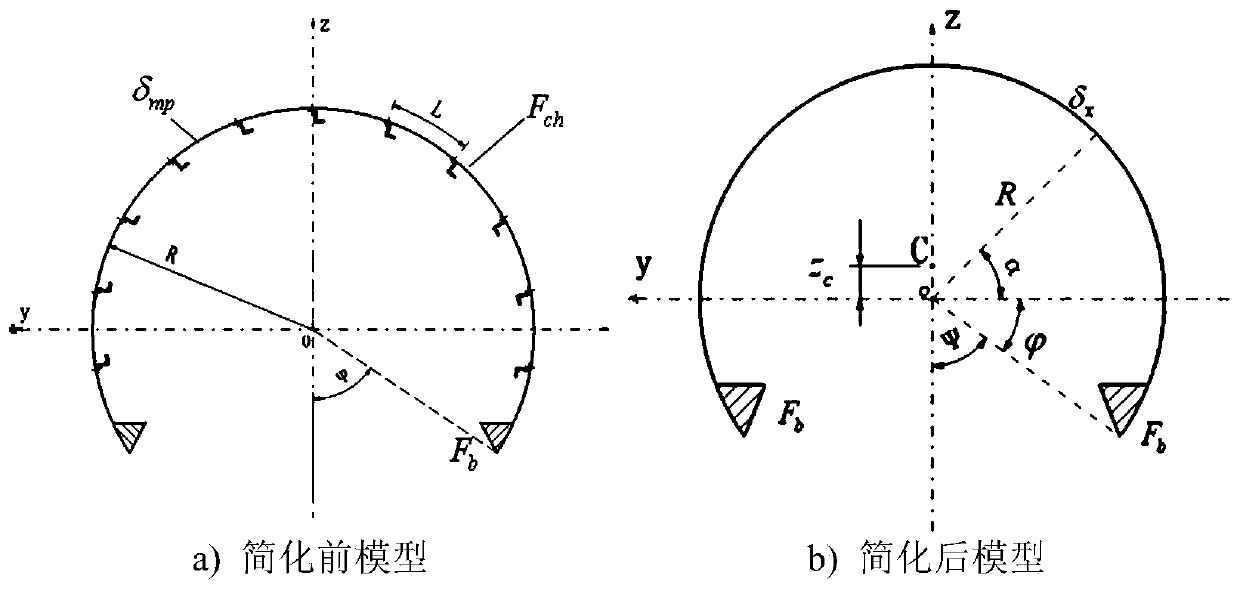

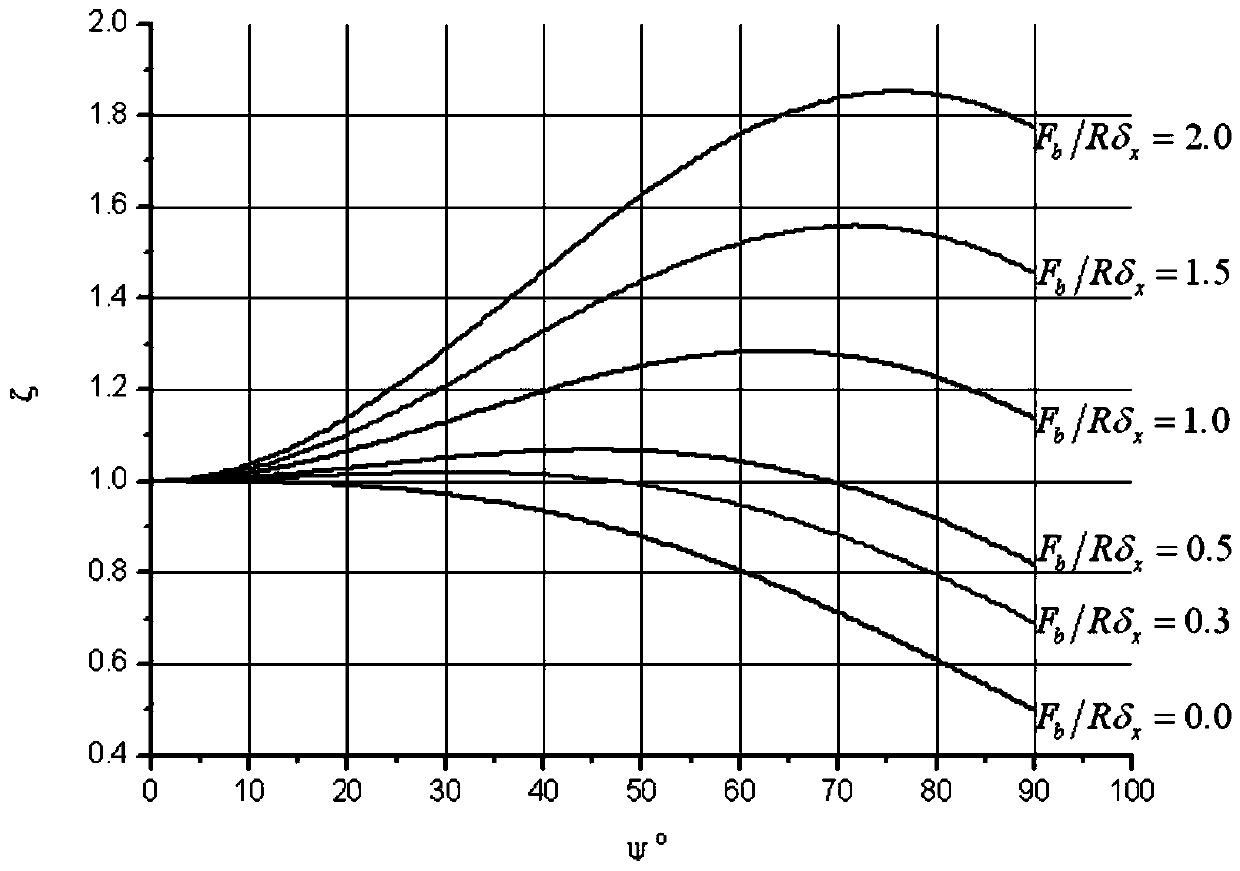

[0032] See attached Figure 1-4 , a method for designing the lateral stiffness of an aircraft large opening structure, comprising the following steps:

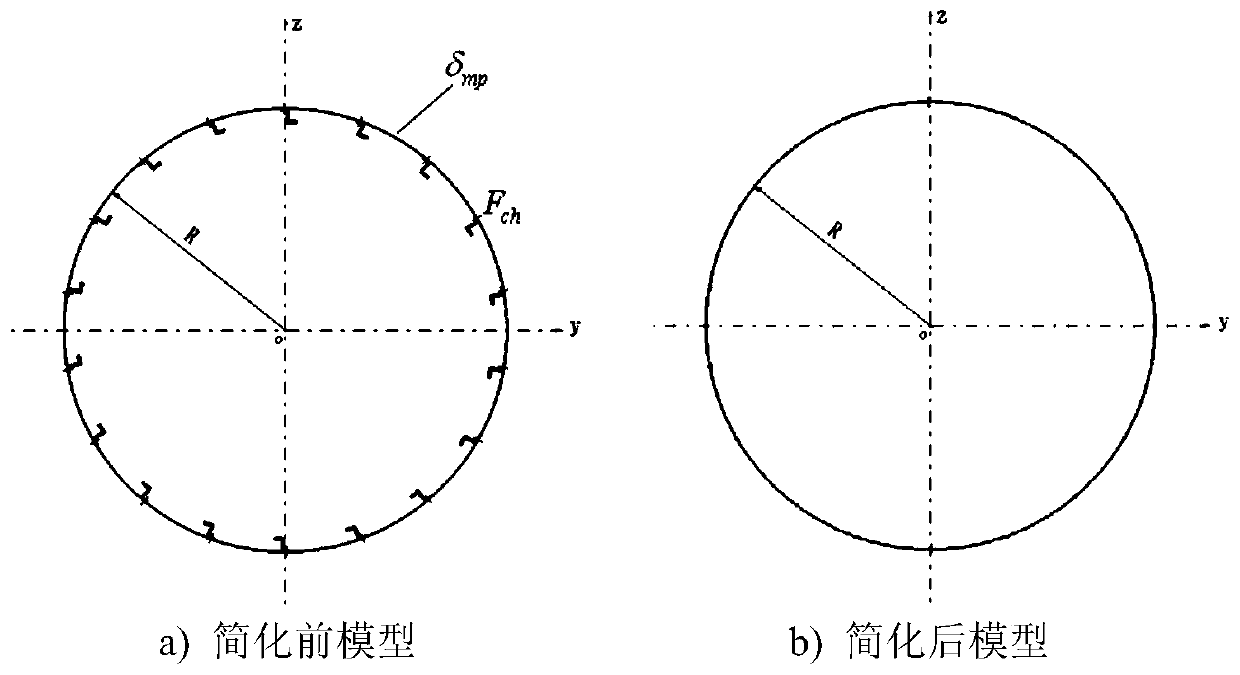

[0033] (1) Simplification of the large opening structure model of the aircraft

[0034] For the large opening structure of the aircraft, a girder is usually arranged at the opening for reinforcement. Typical large opening structures of the fuselage are as follows: figure 1 As shown in (a); during the calculation, the area of the stringer is converted into the thickness of the skin, and the simplified calculation model is as follows figure 1 (b) shown.

[0035] figure 1 middle:

[0036] R - fuselage radius;

[0037] f ch — the cross-sectional area of the girder;

[0038] 2ψ——large opening angle;

[0039] f b — the area of the reinforced truss girder at the opening;

[0040] δ mp - skin thickness;

[0041] δ x - the reduced thickness of the skin,

[0042] the s k — the length of the perimeter of the cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com